The curtain wall glazing system is an amazing design element and integral of modern building architecture and construction. Though from the layman point of view “it’s just glass panels stuck to the building”, however there are intensive specialist design involving several modern technologies, skills are the key drivers of any curtain wall glazing systems exists for the past several decades with buildings around the globe.

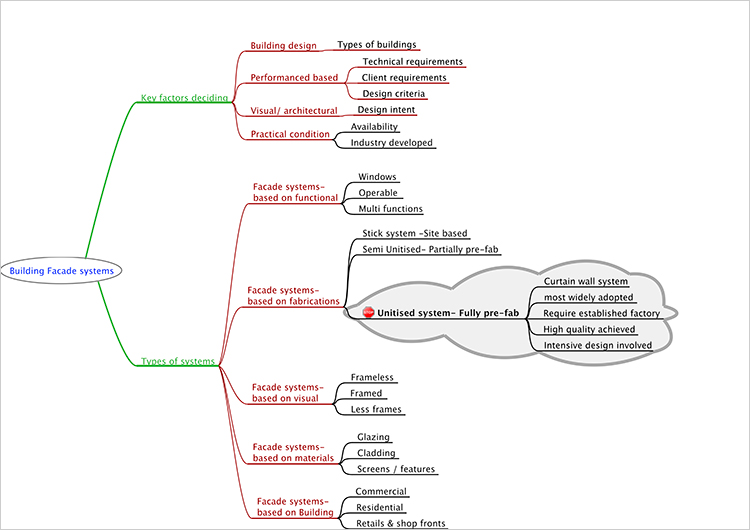

Types of Systems

There are unlimited ways the types of Curtain wall system can be classified, following illustrates the chronology of most widely used façade types.

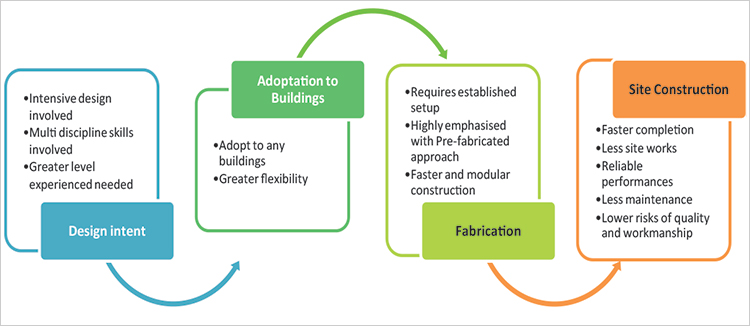

Work Flow or Process

Like any other pre-fabrication approach, a lot of pre-planning, and workings are paramount and make several aspects much more disciplined in the workflow.

The following illustrates the key process of design and implementation.

Architectural Design

Building envelope/building façade is the key communication of the building architecture defining the design intent and desire to achieve a particular visual appeal. Hence the architectural/visual plays a vital role in defining both macro and micro levels of details including materials, joints, etc.

Façade Engineering

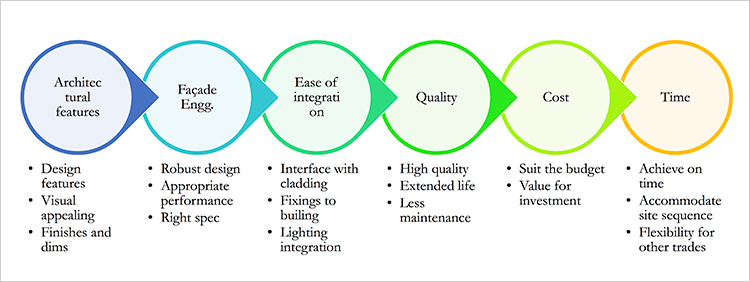

Façade Engineering which deals with several different disciplines such as Structural engineers, Materials Specialists, Product Designers, Mechanical and production specialists. Façade Designers or engineers are the key communicators between architects and constructors, their job is to translate the architectural design into a building design solutions that has been engineered with a greater level of detail.

Façade engineering defines several key visible elements which have architectural impact, hence the approach of the design is architecturally driven with a balanced approach on architectural and engineering requirements. This pushes the boundary of engineering limits and often challenges to achieve the highly optimized, lightweight and simple design solutions.

Product Design & System Design

The concept of pre-fabrication and factory-finished approach has not only helped in the project but has resulted in improved confidence of the design solutions which can be worked out for any complex requirements. The availability and affordability of design and production technologies has made positive impact on the constantly evolving façade industry.

Image 5: Curtain wall glazing – close up inside view

Image 5: Curtain wall glazing – close up inside viewVariety of Designs

There are no boundaries in the design solutions for the Curtain wall systems, there are no rules or limits on the designs but all limits of imaginations and skills of designers.

Though the looks and physical appearance are different, design principles, functions and behaviors are similar.

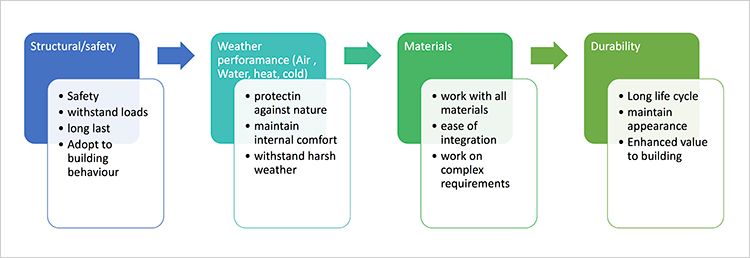

Primary design and functions of curtain wall systems as elaborated below, irrespective of any systems and designs these remains principle design philosophies.

Image 7: The design process

Image 7: The design process Image 8: The design process

Image 8: The design processCase Study

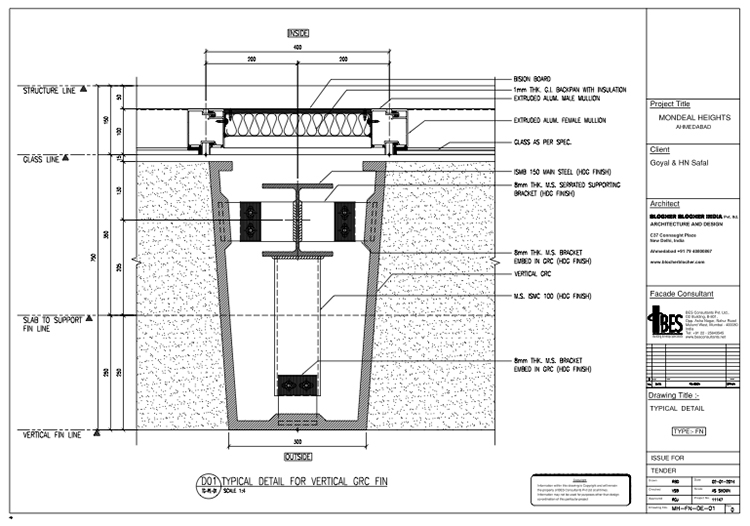

Mondeal Heights, Ahmedabad

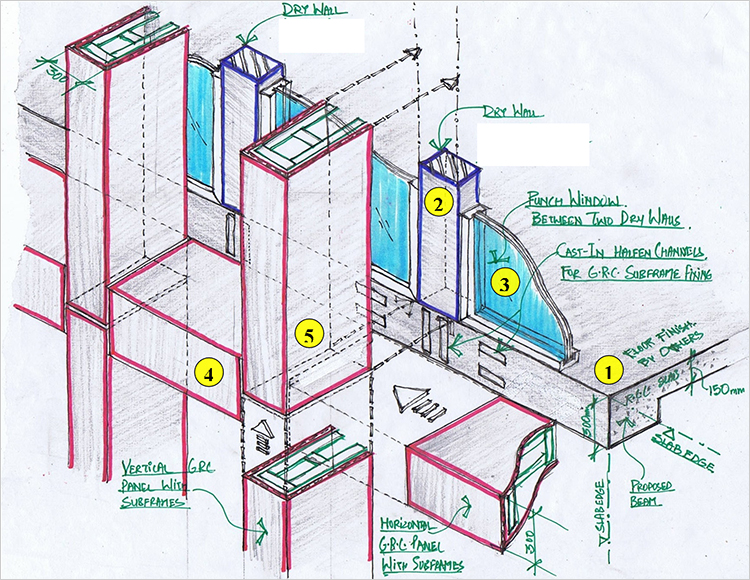

Arriving a most practical and appropriate design solution, which would address the need for iconic architectural building designs and to meet the project timelines, has been a very important and challenging task.

BES has been responsible right from design conceptualization stage since any decisions at this stage will have the greatest impact on the project outcome which was majorly based upon BES expertise.

Various aspects starting from design to final completions were focused on while keeping end in the mind. The following illustrates the design process.

Materials

The design of the building envelope displays a mixed use of glazing and cladding materials.

Glazing System

Careful thoughts were given to the appropriate selection of the glazing system. Out of many other aspects, quality, timely completion and overall cost were the key factors to consider. While quality was set as one of the key aspects, BES decided that a pre-fabricated façade with less site work needed to be implemented.

The following elaborates on the key process and finalization strategy adopted:

Details of Glazing System

A unitised curtain wall system was adopted throughout the project, A Continuous glazing system runs along the building envelope, without any interruptions at the cladding locations. This has given huge advantage of less site work, better weather performance, etc.. This key decision was one of the main reasons for the project’s success, which has been realised upon completion.

Cladding System

| Cladding Material | Pros | Cons | Conclusions |

| Aluminium / ACP panels | Economical and widely available | Require joints and a seamless approach difficult to achieve | Not considered |

| Fibre cement boards | Economical | Require backing supporting frames, long-term durability in question | Not selected |

| FRP – Fibre-reinforced Plastic | Complex shapes possible, durable material | Limited local availability, finishes and local skills not proven | Not selected |

| GRC | Highly versatile material, time-tested approach, good local sourcing and supply | Overall Cost, large scale project on similar application not executed. | Selected |

GRC cladding

Although plenty of as-built references were available, however those completed works are generally ornamental, and decorative such as jalli, screens etc. Large architectural building external applications were nearly none.

BES took the challenges of developing the available vendor and supply chain and bringing adequate technology and construction techniques which has helped the vendor confidence. BES’s practical approach and layman level of design and details have helped the local vendor to implement correctly. In addition to design and detailing, BES spent a considerable amount of time on fabrication and installation methods. A detailed installation sequence, lifting methods and site fixing methods were prepared, tested and monitored by the BES team which has resulted from ease of site construction.

Image 11: Installation method study and preparation of right site construction methods

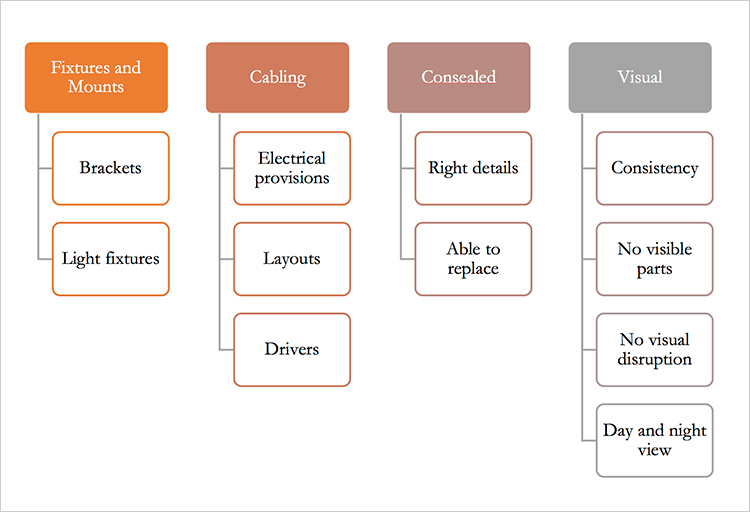

Image 11: Installation method study and preparation of right site construction methodsLighting

Image 13: Lighting integration

Image 13: Lighting integrationFact File:

Project: Mondeal Heights, Ahmedabad

Client: HN Safal Group, Ahmedabad

Architect: Architect BlocherBlocherIndia

BES Scope: Building Envelope Design & Consultancy Services covering concept to completion

Completion: 2016