With the advent of digital design documentation, the last decade has witnessed a significant departure from patterned linear geometries to more irregular and abstract building forms. Since the building façade is manufactured, and manufacturing efficiency governs the time frame and cost of the building, the key to successful implementation lies in the review and optimization of the building design to achieve a cost-effective solution while mitigating large adverse impacts on the building aesthetics that the designer and the owner have committed to.

In 2014, Unilever Indonesia envisioned to consolidate their operations across Jakarta into a single building owned and operated by them. Inhabit was approached to provide façade and BMU Engineering, lighting design, green building consultancy and acoustic/audio-visual design consultancy services. The services were delivered seamlessly by Inhabit’s specialist teams based in Melbourne, Hong Kong, Singapore and Dubai.

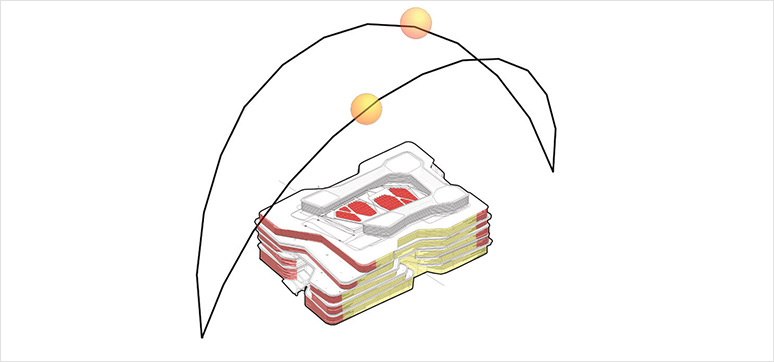

The building’s form was conceived as a perimeter office space with a hollow center, forming a large 5 storey day-lit atrium space with visually connected office spaces forming a multi-story community. The profile of each floor was designed to be dissimilar from the floor below or above creating an abstract ‘ground-scaper’, with internal overhangs forming balconies and external terraces providing landscape opportunities and external break-out areas.

1. Optimum Solar Performance:

Jakarta lies 6 degrees south of the equator making the east and west solar exposure the most critical to the thermal performance of the building. As a feature on the building, the principal architectural intent of the fins and the nosing as shading features was optimized further by iterative simulation by Inhabit’s team of environmental engineers assessing the thermal performance, cost (shades and glass) and desired aesthetics to arrive at a 3-way optimized solution.

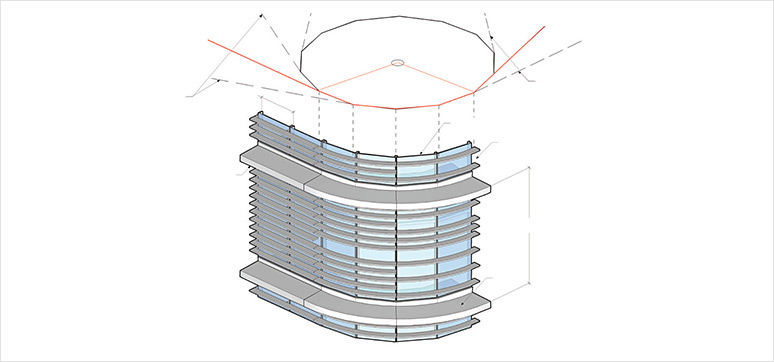

The final solution was with a denser shading (11 fins per floor) on the east and west, fading down to 5 fins per floor on the north and south elevations with the gentle fading on the north elevation to cater to north leaning sun in the months around winter solstice. The large 5 storeyed atrium was designed with 2 skylights providing natural daylighting at the ground level atrium and providing visual connectivity with the sky from a large public area while reducing heat gain.

2. Optimized for Manufacturing:

Understanding the geometry and its desired complexity is the key behind drawing out strategies to optimize it without affecting the critical design features that define it’s visual identity. The change in shape between the floors was facilitated by the façade turning the corner with varying curved lengths leading to multiple tangent conditions forming the straight façade. With the budgetary constraints established, the corner glazing was designed using faceted panels leading to significant cost savings while the shading fins were designed to turn the corner in a bent profile, retaining the architectural intent.

The angle conditions between the corner panels were determined by equally dividing the curved length to a dimension close to 1400mm. While geometrically, this was closer to the architectural intent, it lead to multiple unique mullion sets for most of the corner conditions requiring multiple extrusion die sets. The team worked on the most optimum condition for the architects to reconfigure the corners, optimizing the design further for manufacturing.

3. Optimising the Envelope System:

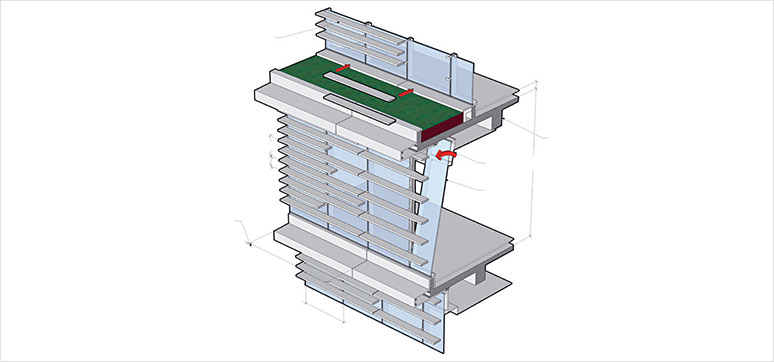

A key part of the architectural intent, the external envelope geometry, was organized to have vertically nonaligned glass surfaces with every floor shifting in relation to the floor below and above. A unitised window wall system was adopted to envelope the building which allowed the shape change between floors while offering the benefits of a factory-finished modular façade construction.

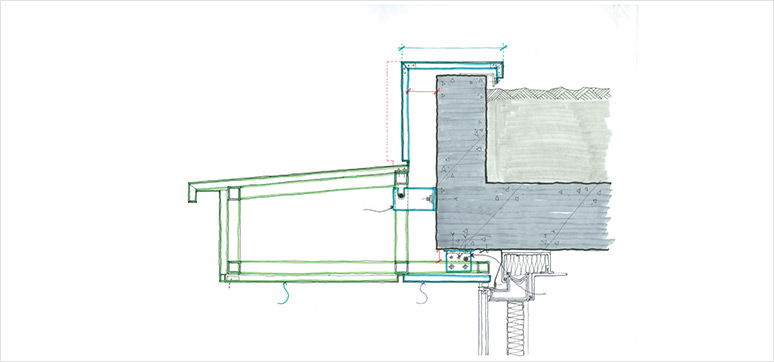

To respect the tight fabrication and installation program and the design intent of minimum joints on the shading fins, the fins were designed to sail over every alternative mullion, reducing the joints to half the number of panels and be site installed with receiving brackets which are a part of the factory assembled panel module. This allowed the building to be sealed in a shorter timeframe for interior fit-out to commence and improved transportation efficiency. The nosing that separates the façade at every floor and allowed the façade plane shift was designed as a slab projection clad in aluminium. In order to reduce tolerance conflict, the shape of the nosing was designed in a metal frame with cladding, and this unit was designed to be installed on a concrete perimeter beam.

4.Signature Lighting Solution:

Given the building’s strong architectural presence, Inhabit’s team of lighting designers worked on a scheme which helped accentuate the buildings geometry, highlighting the nosing features with indirect linear lighting features designed to visually enter the building’s 4 external atrium spaces. The interior lighting was designed using a seamless profile lighting solution, further accentuating the shape of individual floors. At specific locations, a larger application of the same concept was used to provide an illusion of a sunlit soffit and diffused lighting to seating areas below. In order to maintain the interior lighting levels on the ground floor which were largely facilitated by the skylight, the lighting engineers proposed a series of spot lights above the skylight designed to compensate for the reduced natural lighting levels during overcast sky conditions.

As the building design process evolves, it has become increasingly important for the specialists to work with a multi-disciplinary approach at the core of the design process. Unilever Indonesia is a great example of achieving a complex design, from initial concept to building completion over a 3 year time-frame with a team of specialist engineers and designers geared to understand each other’s trade and adding value by providing optimum integrated design solutions.

QUICK FACTS

Project Name: Unilever HQ, Indonesia

Location: Jakarta, Indonesia

Client: Unilever Indonesia

Architect: Aedas (Singapore)

Other Consultants: Royal Haskoning (PM), WTP (QS) Meinhardt Indonesia (Structure and MEP)

Materials Used for façade and fenestration: Glass and Aluminium

Commencement Date: June 2014

Completion Date: Mar 2017

Usable Floor Area: 35,000 Sq m