Picture Credit : mrsiraphol

Glass Balustrade is a common application of laminated glass, wherein the glass panel acts as a structural member that is required to sustain lateral design loads as stipulated by building regulations. Rising awareness about safety related to glass usage instigated by accidents due to human impact is the driving factor for evolution of safety regulations for usage of glass in a building.

Singapore building authorities look for a solution that complies with the most stringent safety criteria, limiting the induced deflection in a free standing balustrade, in “all layers broken” condition to a limit that is deemed to be safe against “fall through”.

Live load testing of a balustrade, laminated with Ionomer interlayer, was done with a leading railing system supplier. The test concluded that the glass balustrade can be designed for sustaining the design loads, not only in “pre-breakage” but also for “post breakage” condition, thus providing a very high redundancy in balustrade design.

Introduction

Global Standards On Balustrades

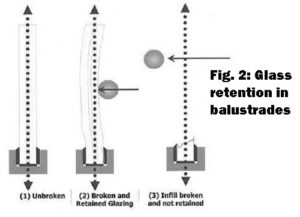

ASTM – E2353 – 06

- Unbroken

- Broken & retained

- Broken & not retained

The standard requires broken glass to be strong enough not to allow a spherical steel ball of diameter 75 mm when pushed with a force of 18 N.

AS 1288 – 2006

German Trav Guideline – 2003

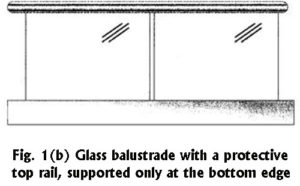

Germany has its TRAV Guideline for balustrades. So far it does not allow cantilevered balustrades, or only with a structural top-railing cap. For balustrades without top-cap a project specific approval and test scenario is required. Similar to Australia, the approval criteria depends on the project and local authority involved (could differ from one state to another).

BS 6180 – 2011

Depending on the type of occupancy of the building, the British Standard has requirements of sustaining below design loads for barriers

- Uniform distributed loads of 0.5KN/m2, 1.0 KN/ m2& 1.5 KN/m2

- Linear live loads of 0.36 KN/m, 0.74 KN/m, 1.5 KN/m & 3.0 KN/m

- Concentrated Live Loads of 0.25KN, 0.5 KN& 1.5 KN

Additionally, the standard requires the glass to be Class A safety glass. However, there are no criteria for post breakage strength[4].

The review of the above important standards & building regulations conclude that Australia & Singapore in particular have a critical approach towards free standing balustrades without any interlinking hand rail. The approach highlights the concern of the authorities for human safety. Clearly, the intent of authorities is to ensure the highest safety level in post glass breakage scenario.

Post Breakage Strength Test For Laminated Glass

Does glass has a strength after it has broken? It all depends on what type of glass and interlayer has been chosen for laminate construction and its boundary conditions. A tempered glass laminate construction with PVB interlayers in a balustrade application may have the desired structural strength but has poor post breakage strength depicted by “blanket effect”. This justifies the safety concerns of building authorities in Australia & Singapore. Ionomer interlayers, rightly address this problem by not only enhancing the stiffness of the glass laminate construction but bring in additional benefits of a very high edge stability compared to standard PVB. Singapore building authorities look forward to elevating the balustrade safety standards by requiring the broken laminate construction, to resist the design live loads within a safe deflection limit of maximum 150 mm when a design load of 1.5 KN/m is applied with all glass layers broken. Clearly, no parallel can be drawn to such a high performance standard of glass balustrade.

In 2015, Kuraray attempted a post breakage strength test on a balustrade having a 2 x 12mm tempered glass laminated with 2.28 mm ionomer interlayer. The test was conducted at an ambient temperature of 33°C, at TUV Singapore. In the test, the broken tempered laminate construction provided sufficient post breakage strength against a “collapse”. However, the broken glass construction was not strong enough to meet the Building Construction Authority (BCA) of Singapore’s requirements as the top edge deflections far exceeded 150 mm when1.5 KN/m linear load was applied at the top edge. Although, this test was a failure, it provided two key learnings – 1. Tempered glass laminate does not have the required post breakage strength. 2. The base of the balustrade need to be made perfectly rigid to mitigate the base mobility issues observed in the built-up U Channel base holding the glass panel.

In 2016, Kuraray & Q Railings together, ventured out to develop a solution that meets the intents of not only the architects but the building authorities (BCA) as well in Singapore. The same test was repeated at at the in-house testing lab of Q Railings at Mumbai in India, which concluded that ionomer interlayers with heat strengthened laminated glass constructions can achieve a very high structural strength capable of safely resisting the design loads in post breakage condition too.

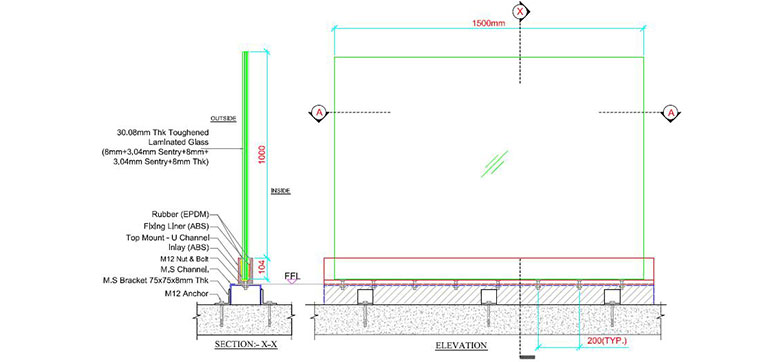

The U Channel base with Acrylonitrile Butadiene Styrene (ABS) Fixing Liner ensured a perfectly rigid base to the balustrade. The glass construction was also changed to a triple laminate construction made with heat strengthened glass instead of tempered glass, with a hope that the middle glass layer “interlocked” between outer glass layers would improve the post breakage strength.

Laminated Glass Construction Details – 8mm Heat Strengthened + 3.04 mm Ionomer Interlayer + 8mm Heat Strengthened + 3.04 mm Ionomer Interlayer + 8mm Heat Strengthened

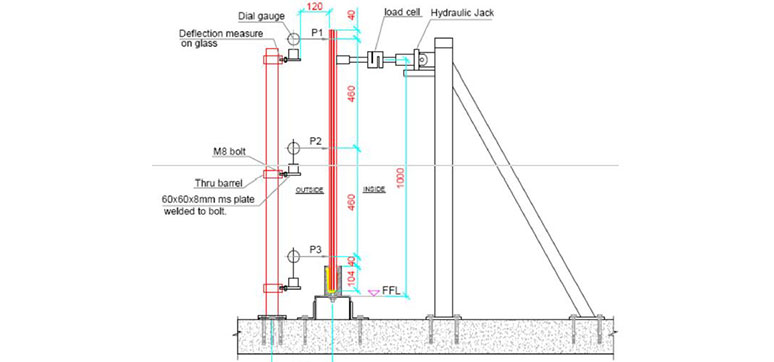

Test Methodology

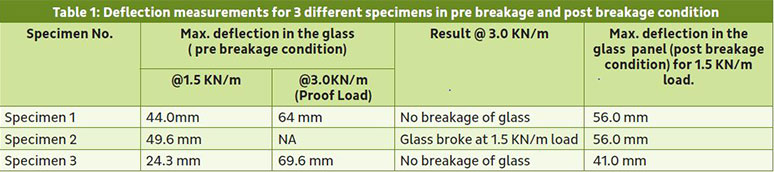

Specimen #2 had an unexpected breakage, probably due to less surface compression stress. The deflections in the Specimens # 1 & 2 in pre breakage conditions for 1.5 KN/m were bit on the higher side because a full rigidity of the bottom edge could not be achieved for the non-standard glass thickness with combination of two different standard ABS wedges. For Specimen # 3, the base stiffness was enhanced by Q Railings, using slightly thicker ABS wedges which resulted in significant reduction in top edge deflections of the panel in pre and post breakage condition[5].

Conclusions

Advanced structural interlayers like Ionomers, when used in a triple layer heat strengthened glass laminate construction, significantly enhance the structural integrity of the glass balustrades to resist the design loads in post breakage condition as well, thus meeting the most stringent safety norms laid down by countries like Singapore & Australia.

References

- ASTM E 2353 – Performance of Glass in Permanent Glass Railing Systems, Guards, and Balustrades

- AS 1288 – 2006 – Glass in Buildings – Selection & installation

Building Code of Australia – 2015, 2016 - BS 6180 – 2011 – Barriers in and about Buildings – Code of Practice Testing of Glass Balustrade System, free standing without cap rail / handrail by Q Railing India for Kuraray India Pvt. Ltd.