The design and structural performance of laminated glass in overhead glazing applications like canopies and skylights is very critical as it has an impact on the safety of occupants of a building and its maintenance workers. For such applications, the post-breakage strength of laminated glass construction is of utmost importance. Pre-breakage strength can be predicted with reasonable accuracy by FEM technique (Finite Element Method) based software packages, which allows the user to input mechanical properties of viscoelastic inter layers along with glass.

This helps in inter-layer-based differentiation of pre-breakage structural strength and design optimization. However, the post-breakage strength of glass is still a little-known area as analytical models for this are inconclusive so far and thus destructive testing is the only reliable solution. This article will present impact and load testing, simulating the accidental fall of a maintenance worker. It was done to assess the “fall through” resistance of point fixed laminated glass constructions having varying inter layers, like Standard PVB (Polyvinyl butyral), Ionoplast Inter layer (SentryGlas®) and Stiff PVB. In addition, medium duration (30 mins or more) post-breakage strength tests driven by the new requirements set in place by German Standard pr DIN 18008-6 were conducted at sub-zero (-20°C), room temperature (+21°C) and at elevated temperatures of +50° Celsius.

Introduction

Laminated glass is commonly used for applications involving a potential risk of injury to humans. A typical laminated glass construction consists of two or more glass panes bonded together by an inter layer such as Standard PVB, Ionoplast Inter layer (SentryGlas®), Stiff PVB or EVA (Ethylene-vinyl acetate). Laminated glass has become a major interest in structural applications after the adoption of the “Effective Thickness Method” by ASTM E 1300 in 2009. Now, more and more structural and façade engineers are becoming aware of the viscoelastic behaviour of the interlayers. Thus, now they are considering temperature and load duration as of the important factors which influence the structural performance of laminated glass construction.

FEM technique-based software like SJ Mepla can model the laminated glass as a composite material by incorporating the time and temperature-dependent properties of the inter layers. This allows the engineers to differentiate between the structural performances of laminates with various types of inter layers. However, for post-breakage strength, they still have to rely on destructive strength testing methods. Post breakage strength is a result of some complex parameters which are hard to model analytically so far. An attempt has been made to compare the qualitative residual strengths of laminated glass panels through destructive impact testing for a canopy application.

Laminated glass has a significant improvement in the post breakage strength over a monolithic layer of glass. The glass fragments adhere to the inter layers so that a certain remaining structural capacity is obtained as the glass fragments ‘arch’ or lock in place. This capacity depends on the fragmentation of the glass and increases with increasing fragment size. Therefore, laminated glass elements achieve a particularly high remaining structural capacity when made from annealed or heat-strengthened glass that breaks into large fragments. The post breakage behavior furthermore depends on the inter layer material.

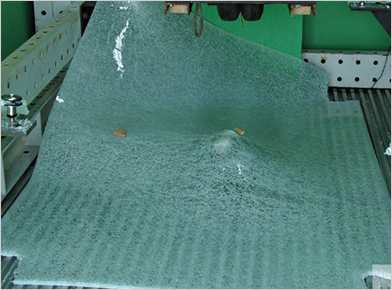

The most common interlayer is PVB whose mechanical properties are heavily dependent on temperature and load duration. At room temperature, PVB is soft with an elongation at a break of more than 250 per cent. For higher temperatures and load durations, the shear transfer is greatly affected. Low stiffness of the PVB interlayer results in the “Blanket Effect” (Fig. 1) as soon as the glass breaks even for vertical applications because of the self-weight of the panel, especially with large panel sizes and minimal supports. SentryGlas® Ionoplast Inter layer, from Kuraray (originally invented by DuPont), was developed with the aim of achieving higher stiffness, temperature resistance, and resistance to tearing in point fixed rule applications. This helps in achieving superior post-breakage strength and design redundancy. Table 1 gives a comparison of the mechanical properties of SentryGlas® Ionoplast Inter layer with PVB.

| Table 1: Comparison of Mechanical Properties of SentryGlas® Ionoplast and Standard PVB | |||||

| Interlayer Type | Density | Young’s Modulus@ 50°C, for 1 hour load | Poisson Ratio | Coefficient of Thermal Expansion | Tensile Strength |

| Ionoplast (SentryGlas®) | 850 Kg/m2 | 12.6 MPa | 0.5 | 12.5 x 10-5/°C | 34.5 MPa |

| Standard PVB (Butacite®) | 1070 Kg/m3 | 0.16 MPa | 0.5 | 2.2 x 10-4/°C | 20 MPa |

| Stiff PVB (Trosifol® EXTRA STRONG) | 1081 Kg/m3 | 1.20 MPa | 0.5 | 1.6 x 10-4/°C | 32 MPa |

Table 1 gives a comparison of the mechanical properties of SentryGlas® Ionoplast and Standard PVB interlayers. Post-breakage strength is significantly affected by the breakage pattern of the glass layers, support conditions, and temperature. The breakage pattern of glass can be a big variable even for the same type of glass and this makes analytical modelling of its post-breakage strength a nearly impossible task. Thus engineers have to rely on destructive testing for this. Post-breakage strength can be categorized as follows.

Code Requirements for Post-Breakage Strength for Overhead Glazing Constructions

pr DIN 18008-6 Standard and former GS Roof Glazing Guidelines (Maintenance workers on the roof) are valid for different overhead glazing constructions like framed or point-supported designs when access for maintenance or cleaning activities will be allowed.

In Germany, the overhead glazing that is accessible for maintenance and cleaning should be tested for post-breakage strength. The impact body is a standardized soft body impactor weighing 50 kg. After impact testing, the specimen has to be loaded with a single load of 1.0 KN, applied to an area of 200 x 200 mm. This should represent a single person standing on the glass surface. After the breakage of the uppermost glass sheet, the whole glazing element must stay on its supports for at least 30 minutes. After this, the impact body must be dropped from a height of 900 mm and has to hit the specimen in locations that cause maximum glass and support damage. The test is successful if the specimen does not slide from the supports, the impact does not penetrate the laminated glass and no dangerous glass fragments fall down2.

Testing carried out:

- Immediate Post Breakage Strength against “fall through”

- Medium Duration Post Breakage Strength Testing (More than 30 mins. as per prDIN 18008 – 61)

Separate tests were conducted for both types of strengths and the same have been presented in this paper.

Structural Glass Analysis Pre-Breakage

The structural performance of laminated glass in frameless point-supported overhead canopy applications is very critical because of high-stress concentrations at the fixing points. In these applications, glass elements are held in position to sustain the imposed load without any structural framework running along the edges. Instead, the panels have metal patch plates or point fixings called rotules or spider fittings.

In these types of applications, the flexural behaviour of the panel is very different from the one for a framed glass panel as large stress concentrations are observed around the rule fixings. Structural analysis for one such application was performed in SJ Mepla software.

Table 2 gives a comparison of structural performance results in terms of induced deflections and stress levels in a glass panel of size 1194 mm x 1500 mm subjected to a point load of 50 Kg for a duration of 1 hour. The analysis has been performed on the following glass constructions.

-

-

- 6 mm Tempered + 0.89 SentryGlas® Ionoplast + 6 mm Tempered

- 6 mm Tempered + 1.52 Standard PVB + 6mm Tempered

- 12 mm Monolithic Tempered Glass ( Control Sample)

-

A control sample of a 12 mm monolithic tempered glass panel was analysed to compare the extent of coupling provided by the interlayers. Table 2 gives the numbers for deflection and stresses in the panel for the same load and boundary conditions.

| Table 2: Structural Calculation Results | ||

| Laminated Glass Construction | Stress | Deflection |

| 6mm FT-Glass+ 0.89 SentryGlas® Ionoplast + 6mm FT-Glass | 66.47 MPa | 14.68mm |

| 6mm FT-Glass+ 1.52 Standard PVB + 6mm FT-Glass | 154.67 MPa | 28.74 mm |

| 12 mm Monolithic FT-Glass | 64.62 MPa | 14.93 mm |

Laminated safety glass produced with high strength, high stiffness Kuraray inter layers is considerably lighter than laminates produced with standard polyvinyl butyral (PVB), as the comparison shows. The SentryGlas® Ionoplast inter layer is approx. 100 times stiffer and five times stronger than Standard PVB, the transmission of load between the two sheets of glass in the laminate is almost perfect, leading to a rate of deflection that is less than half of that achieved by laminates using PVB of the same construction. Consequently, the laminate can either be used to bear greater loads or – as in the case above – reduced in thickness and weight without compromising safety.

The above results conclude that even at an elevated temperature range of 50ºC, SentryGlas® Ionoplast interlayer provides an efficient coupling to the glass layers to match its structural performance with an equivalent monolithic glass whereas PVB inter layer because of inefficient coupling lags behind in structural performance as both stresses and deflections in PVB laminates are around 100 per cent more than those in SentryGlas® Ionoplast laminates.

In order to remain within the deformation limits, the laminated glass panels with Standard PVB should have had to have been considerably thicker than those made with the SentryGlas® Ionoplast interlayer. Their weight would also have been correspondingly higher. In order to ensure the required safety levels, a much more substantial supporting structure would have been required than the intended light-dimensioned point fixing system designed for the glazing. The use of such a structure would have spoilt the desired transparent effect of the glazing, particularly when illuminated from above. Following intensive laboratory testing confirmed the FEM calculations of the simulation by physical strength testing.

Immediate Post Breakage Structural Performance through Impact Testing

Impact tests were done at Intertek ATI Inc. York, Pennsylvania by dropping a soft bag weighing 100 Kgs (typical weight of maintenance working along his tools and tackles) from a height of 1.20 m at a test temperature of 50ºC. The test method simulates potential loading from installation and /or maintenance workers in distress. The panels were conditioned at 50°C for 1 hour before the test. The test set-up was enclosed with insulated panels to ensure there is no variation in test results due to temperature. The insulated panels were removed just before the impact.

Laminates made from SentryGlas® Ionoplast interlayer provided a barrier against the impactor. The impactor was removed after 15 minutes without any tearing of inter layer observed at the rotules. Whereas laminates made from EVA, Standard PVB and Stiff PVB collapsed as soon as the impactor strikes and failed to act as a barrier.

The next level of test programs shall be aimed at knowing the minimum inter-layer thickness that is required for a glass panel to pass the post-breakage strength requirements set by standards with temperature as the key variable factor.

A. Post Breakage Strength Testing (30 Minutes or more)

German Standard pr DIN 18008 – 61, (Glass in Buildings – Design & Construction Rules – Additional requirements for walk-on glazings in case of maintenance procedures) in February 2015, has made the post-breakage performance test necessary. The new regulation requires a laminated glass construction to sustain the weight of 100 Kg for at least 30 minutes after breakage of top layer of glass. First, the panel is subjected to an impact made by dropping a twin tyre impactor which weights 50 kg from a height of 900 mm. This is followed by imposing a load of 100 Kg for 30 minutes on an area of 200 x 200mm. After the breakage of the uppermost glass layer, the whole glazing element must stay on its supports for at least 30 minutes. The test is successful if the specimen does not slide from the supports, the impact does not penetrate the laminated glass and no dangerous glass fragments fall down2.

Testing

Post-breakage strength tests on point-supported glass panels (1500 mm x 2000 mm) for a typical canopy application were conducted at University of Armed Forces in Munich4, Germany. 9 glass panels with each of 4 different inter layers: SentryGlas® Ionomer (1.52 & 0.89mm), Stiff PVB (1.52mm), and Standard PVB (1.52 mm) were prepared for testing at 3 different temperature scenarios. (Table 3)

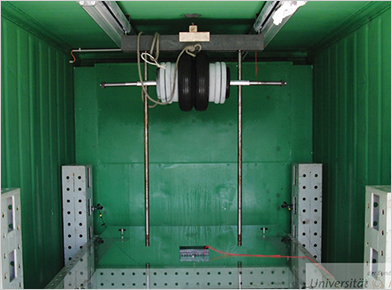

The objective was to know which inter-layer type laminate construction can pass the requirements set by pr DIN 18008-6 at 3 different temperatures (-20°C, +21°C and +50°C). 3 panels were tested for each temperature scenario. As a soft-body impactor the EN 12600 Pendulum Test “Double-Tire“ impactor in a new vertical position will be used. An attempt was made to know the ultimate capacity of the laminates. However, the test apparatus had a limitation of applying a maximum load of 400 Kg. The laminates were conditioned for at least 3 hours for each temperature scenario.

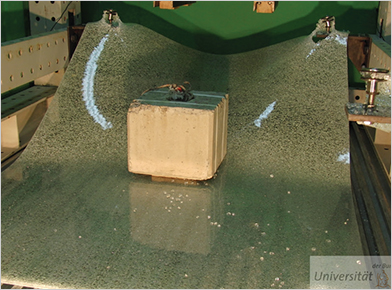

The test chamber (Fig. 2) had a temperature control mechanism for a temperature range of -25°C to +50°C. The laminate construction with all different types of interlayers was strong enough to withstand the impact against any breakage. Therefore the upper layer of laminates in each case had to be broken manually with a centre punch. It was followed by placing a 100 Kg concrete block on the glass panel for 30 minutes. The test was aimed at knowing the ultimate post breakage performance limit so the load was ramped up to 400 Kg in increments of 100 Kg, with a 15-minute time interval between each load increment. Laminates with SentryGlas® Ionoplast and Stiff PVB inter layers sustained this load of 400 Kg without collapse at -20°C and + 21°C temperatures (Fig. 3) Whereas in Fig. 4, Standard PVB laminate could not sustain the 100 Kg imposed load at +21°C as it collapsed in few seconds when load was placed due to tearing of the interlayer at the rotules.

| Table 3: Glazing Constructions | |||

| Dimension of the Specimen: 1.500 mm x 2.000 mm | |||

| Supports: PAULI & SOHN Rotule System 751260 VAM M16 (not fully motion restricted) | |||

| Laminate Construction 1 | Laminate Construction 2 | Laminate Construction 3 | Laminate Construction 4 |

| 2 x 6 mm FT-Glass | 2 x 6 mm FT-Glass | 2 x 6 mm FT-Glass | 2 x 6 mm FT-Glass |

| 1.52 mm Interlayer | 1.52 mm Interlayer | 0.89 mm Interlayer | 1.52 mm Interlayer |

| Butacite® PVB | Trosifol® Extra Strong | SentryGlas® Ionoplast | SentryGlas® Ionoplast |

| “Standard PVB” | “Stiff PVB” | “Ionoplast” | “Ionoplast” |

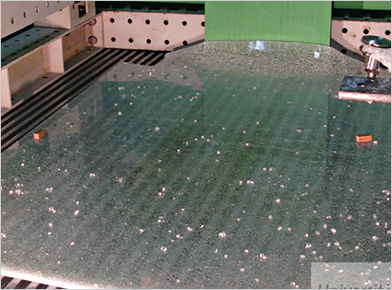

At an elevated temperature of 50°C, broken laminate construction with Standard PVB & Stiff PVB inter layers could not sustain their own self weight as they collapsed (Fig. 5 & Fig. 6) soon after the breakage of both layers. Whereas, the laminate construction made with 0.89 mm SentryGlas® Ionoplast inter layer sustained a weight of 100 Kg for more than 30 minutes and collapsed when load was ramped up to 200 Kg. Similarly, 1.52 mm Ionomer laminate could sustain a load of 200 Kg for more than 30 minutes after breakage and collapsed when load was ramped up to 300 Kg.

Fig.2: Test set-up before impact, installed in a climate chamber

Fig.2: Test set-up before impact, installed in a climate chamber Fig.4: Collapsed Standard PVB laminate with 100Kg at +21°C

Fig.4: Collapsed Standard PVB laminate with 100Kg at +21°C Fig.5: Broken Standard PVB laminate collapsed at +50°C

Fig.5: Broken Standard PVB laminate collapsed at +50°C

B. Deflection Measurements for Estimating Modulus of Broken Laminate

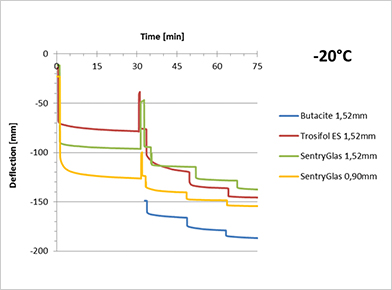

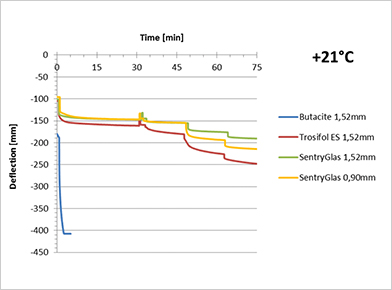

Deflection measurements were made during the test for all three temperature scenarios to make an estimate of the post-glass breakage strength of the laminate constructions. At –20°C the 1.52 mm Ionomer laminate demonstrated the lowest deflection after 30 min (Fig. 7), whilst at +21°C both SentryGlas® Ionoplast laminates (1.52 and 0.89 mm) outperformed the PVB laminates (Fig. 8).

Conclusions

- At -20°C, laminates made from the 4 interlayer candidates i.e 0.89 mm SentryGlas® Ionoplast, 1.52 mm SentryGlas® Ionoplast, 1.52mm Standard PVB, 1.52 Stiff PVB pass the post breakage strength requirements of the new German Standard pr DIN 18008 – 6.

- At -20°C, all 4 candidates had their ultimate strength more than 400 Kg as there was no collapse of the panel due to tearing of the interlayer at rotules.

- At +21°C, SentryGlas® Ionoplast and Stiff PVB laminate pass the post breakage strength requirements of DIN 18008 – 6 but Standard PVB laminate does not (for this type of construction).

- At +21°C, 0.89 mm & 1.52mm SentryGlas® Ionoplast laminate had almost similar post-breakage strength till about 45 minutes from the breakage.

- For tropical climate regions where the ambient temperature is more than +45°C, SentryGlas® Ionoplast interlayer laminates meet and exceed the requirements of pr DIN 18008- 6 Standard as the only interlayer material.

Please note that the findings are valid for point fixed fully tempered glass and the described testing set-ups only. Glazing construction using heat-strengthened glass, annealed glass and/or different fixations systems could show a different performance. Further testing and research will be conducted to get a better understanding of the post-glass breakage behaviour of laminated glass and to develop appropriate design methods.

Modern construction without laminated glass is no more an option to meet the architect and specifiers needs and at the same time meet codes and regulations in place. At the same time, global challenges of the industrial world are calling for some new glazing solutions. Interlayer suppliers have been able to address some of these challenges through innovative products and will continue to do so in the coming years.

More recently, new requirements have added challenges to the performance of laminated glass:

- UV filtration performance

- Acoustic performance

- Larger glass panes and minimally support edglass.

- Post breakage performance

- Enhance glazing system performance for:

- Blast and ballistic resistance

- Very high wind load and debris resistance for hurricane sensitive areas

- Concerns about the safety performance of tempered glass

- Durability and performance in open edge and silicone sealed applications.

- Changes is colour and transparency/translucency

- Material inclusion and combination with glass coatings

Laminated glass is also increasingly challenged to help meet the energy control requirements imposed on new and retrofitted buildings. These requirements have led to a dramatic increase of inter layer solutions. At the beginning some of these challenges were met through modification of the original “automotive” PVB: Inter layer thickness ranging from 0.38mm up to 4.56mm or more, sheet size increase and introduction of colours for architectural applications including translucency. However, as the architectural laminated glass market was maturing, the original PVB recipe proved to have its limitations for architectural applications. This led to the modification of the PVB recipe for applications such as enhanced acoustics, and the development of other polymers such as SentryGlas® Ionoplast and EVA.

This summary illustrates that the use of advanced inter layer, thanks to their stiffness and retained transparency – even after many years of use, presents new opportunities for architects and engineers to carry out cost-effective modernization projects and innovatively adopt laminated safety glass in construction. Such glass is already being used on a large scale for architectural projects such as glazed balustrades, floorings, staircases and pedestrian bridges – bringing with it additional benefits in terms of the preservation of valuable resources.

References

-

- Draft Standard / DIN prEN 18008-6, Beuth-Verlag, Berlin

- GS-BAU-18, Merkblatt ZiE-Nr. 3A

- ANSI Z.97 Standard / Safety Glazing Materials Used in Buildings – Safety Performance Specifications and Methods of Test

- Test Report Nr. b-03-14-08 / Universität der Bundeswehr, Munich