Please brief us about your Sobha Façades and their journey.

Our humble story begins 4 years ago in Dubai, with a mere 5 employees entrusted with the engineering and design of the façade and glazing works for all the in-house projects of Sobha Realty.

We did not want to opt for the conventional route and follow dated practices. Rather, we mustered up the courage to create a vision for ourselves and set out to rejuvenate the mostly unorganized industry. Naturally, there were many ups and downs like most others have experienced. Often there was an easier, albeit a less than ideal, way to just deliver the product. But our focus has always been on the problem and not on the solution.

We viewed our challenges as opportunities to grow and learn. And today, we are a well-established organization that has risen above the competition in the façade, curtain wall, and aluminium fabrication industry. What started as a simple contracting company, soon became a fully-fledged manufacturing unit with excellent installation capability on-site.

But the journey was not simple, in this highly unorganized façade industry, we were struggling with high wastages, increased labor costs, and low efficiency. Modernizing and streamlining a traditionally bulky, and labor-intensive business model is no easy feat, and we too thought it was impossible.

We wanted to focus on optimizing the process right from the grassroots until the end installation to create value at every layer. We are aware that it is difficult if we practice age-old practices and hence wanted to digitalize and follow a proven methodology like Lean and six sigma to improve the overall efficiency and quality.

As our workforce kept growing to the 500-strong team we have today, we honed the talents of the individuals, identified strong leaders, and gave all employees the space to grow and express themselves. This has greatly contributed to the healthy, prospering work environment we enjoy at Sobha Façades.

Now we are enjoying a good presence in the industry and planning to scale up to cater to global needs with our sophisticated, sustainable, and smart solutions.

In addition to all the IMS certifications, very recently Sobha Facades is honored with prestigious ISO 18404 accreditation for implementing Lean & Six- Sigma Methodologies in all its processes. We are the first in the world from façade and many other industries and interestingly first private company in the GCC to be certified.

Tell us about your product offerings. What benefits do they offer?

We design and fabricate aluminium doors & windows, façades, claddings, unitized curtain walls, skylights, balustrades, louvers, pergolas, and frameless façades. We strive for the highest level of precision, top craftsmanship, and efficient processes.

We use Lean Six Sigma methodologies to optimize the processes and add value to offer thorough customer delight. Sobha Façades has developed in-house systems for aluminium metal claddings, sliding doors, hinged doors, and windows, allowing us to deliver high-quality materials at an affordable and competitive price. We also have partnered with European manufacturers to deliver using their systems.

Name some of your projects.

Our products are used for all properties in the Sobha Hartland which is an 8 million sq. ft waterfront sustainable community of high-rise towers, beautiful villas, high-end townhouses, international schools, and commercial spaces located in the heart of Dubai.

Currently, we are not catering to the outside Sobha clients in UAE as we are not interested in the subcontract method which the façade industry is following here. But we are definitely interested in partnering with UAE clients on a design, manufacture, and supply basis, where we can add immense value with our efficient product delivery and quality.

Could you please tell us about your manufacturing facility and capacity?

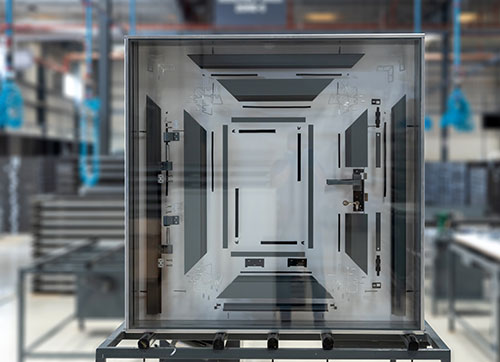

With two factories located in the Emirates Industrial City, Sobha Façades is the most efficient façade fabricator in the region with state-of-the-art technology and machines.

We have a wide range of equipment including most modern CNC machines capable of manufacturing different façades with the utmost precision. Each workstation is designed with individual pneumatic tools to ensure high levels of accuracy. The facility can produce premium quality façade systems that comply with international standards.

We consider ourselves as one of the most organized companies in the GCC and strive for continuous improvement in all processes wherein almost 750 Kaizens (ideas) are recorded by our employees/ technicians in 2021.

Our manufacturing philosophy is leveraging Technology and Lean Six Sigma practices to increase efficiency and promote an innovation-driven culture inside the shop floor.

We believe in staying up to date always and training our workforce with the best practices periodically. We intake mostly fresh graduates and groom them with generic, Lean & Six Sigma methodologies along with technical teachings. In fact, all our new joiners must undergo a 2-week induction/training program where they are trained to meet Sobha standards.

We continue to challenge ourselves to be innovative, analytical, and always at the forefront of bringing change. This is how we keep complacency away and continue to set an example for the façade industry.

What do you see as the main challenges faced by your industry?

The construction industry struggles when it comes to efficiency and optimization, but the façade contracting sector suffers even more. Since it is a division of the traditional construction industry any inefficiencies in the construction industry are passed down to the façade industry. Adding to that, the Façade contractors always come late in the project and are expected to go out first!

A unique challenge in the façade industry is the fact that nearly every project will require different designs and have unique engineering constraints and requirements. This makes standardization, automation, and mass production extremely hard to achieve. The façade contracting industry needs innovations, improvements from the traditional processes, and better communication across all stakeholders to cut down wastages.

The unorganized supply chain is the next bottleneck where things get worsened by delayed deliveries. Transparent communication by all stakeholders should be improved.

It is imperative to get skilled manpower both blue-collar and white-collar to deliver and install façades efficiently, but there are no institutes that provide dedicated façade training. So, getting a skilled workforce meeting world-class standards is also a challenge in the industry

The pandemic has affected all businesses. How are you coping with this situation?

As many were firing, we were hiring employees during the period because we anticipated the risk early and planned the supply chain to an extent. We couldn’t succeed 100% but we managed to tackle this hiccup and feel sorry for many of our friends who went bankrupt during these unforeseen crises. Thanks to our in-house projects and backward integration of the Sobha group where we had diversified projects in hand and worked in full swing even during the pandemic.

It is in our DNA to avoid wastages and optimize the process by value stream mapping suiting the need thereby cutting costs. For example, during the pandemic, we reworked the transportation routes, and logistics supply, and almost 80% of the products are changed to prefabricated in the factory to deskill the workers at the site, reducing installation time without compromising on quality.

What are the characteristics of a well-designed façade system?

Any system should perform as per functions designed meeting at least air, water, and structural performance. However, most of the metrics are not witnessed at installation on the site. This happens because correct processes are not followed, and systems are not fabricated and installed in the right way.

Many projects as per specifications have passed in the laboratory but have not been performed in the actual installation due to inefficiencies in each process.

For me, a good system should be simple, easy to fabricate, and less skill required to install. Most of the assembly should be made in the factory and should perform in any conditions for which it is intended considering factors like site tolerances, etc.

What are the major opportunities for your business in the Middle East?

Sobha as a group has many luxury projects in the pipeline and we are determined to supply our products for all our in-house projects. There’s good growth potential in this region, the leaders of the nations are envisioned to get a global branding with the best infrastructure and the world is looking to UAE as the best destination. We are gearing up to choose the best opportunities to serve this region.

Because of the tough times, many immature companies are filtered, and now commercial benchmarks have to be improved for a healthy façade industry.

We foresee that the façade industry in the Middle East will come out of this unorganized subcontract model to a more matured manufacturing/installation model, where the heart and soul of the operation will be pre-fabrication and deskilling site installation.

What are your goals and plans for the next 4-5 years?

Our plan now and in the future is to focus on a 360-degree approach in optimizing and revitalizing the façade industry and embrace the change to shift digital/automation in possible means. We want to contribute to the global audience and practice better sustainability measures in the coming years.

We always want to keep innovating and keep evolving in this expedition and to stay one step ahead by continuously improving to be a role model for the industry always.