A curtain wall is a nonstructural exterior covering of a building that is connected to the frame and used to withstand the effects of environmental elements including wind, rain, etc. For better performance of the façade of the buildings, it is very important to carefully study the curtain wall during the design stage to take into consideration all of the performance criteria such as air and water tightness. The selection of the right material and the design elements for the curtain wall are critical to giving longer life to the building. We interviewed a few top names from the Middle East’s façade industry to learn more about effective curtain walling. Here are experts’ views and some trips that should be followed.

The Key Elements of Curtain Walling Systems

Douglas Sum, Partner, and Co-Owner, of Heroes Architects and Engineers, believes that the key elements of the curtain wall system, or the definition of façade, are the ‘Barriers on the outer skin of a building, for separating interior space from the exterior environment. “Although people might immediately think of glass, and aluminium as the key elements of the curtain wall system, I would consider all of the components inside the curtain wall system indeed serve the same purpose – to confine a space from the (severe) external environment”, he adds.

Susanna Noureddine, Associate Façade Consultant, Ramboll explains every good curtain wall system has to be designed considering five key elements: safety, quality, cost, aesthetics, and constructability. All of these elements are very much linked with each other to achieve the desired outcome. Safety and constructability are aspects we do not compromise. Unfortunately, we have seen and heard it often enough that cladding and glass panels are falling; a fire erupts over entire elevations, and buildings become uninhabitable due to poor construction. In brief, quality is part of these two aspects. She adds aesthetics and costs are, to a certain extent, flexible factors. Value engineering and cost-cutting are often brutally left out in the aesthetics of the building. Materials are either replicated or entirely replaced by ‘cheaper’ usually aluminium panels or a render finish. There is a particular benefit for most of the projects, but often this compromises the architectural intent. Quality is also associated with indoor comfort. The better the thermal performance of the curtain wall, the better your indoor comfort. The Shading Coefficient and U-value are decisive and will increase the cost of aesthetics and quality.

Miguel Fernandez, Senior Façade Consultant, AESG mentions, “We tend to think that glazing and profiles are the key elements of a curtain wall system, however, we should not underestimate the importance of other elements like gaskets or fixing accessories, the correct design of these elements is truly a key part of assuring the required performance of the whole system. Gaskets are in great part the responsible parts for the air and water tightness of the curtain wall. Inside that category of accessories, the design of the curtain wall brackets is of key importance to avoid installation problems, brackets design should be able to accommodate the construction tolerances and the differential movements”.

Key Characteristics of a Well-Designed Curtain Wall

Sum says, following up with the point above, a suitable barrier is a well, design curtain wall. He recommends using the metaphor of ‘shopping for a winter jacket’ to define the right curtain wall – what is in your mind when you need to buy a jacket for hiking in the snow? He believes it must keep you warm (thermal performance); fit your body so you can move freely (allow movement); not make you feel sweaty (breathable but not air leaking); be scratchable (structural safety and durability); not burn when you are closed to a campfire (non-combustible); look nice and meet your style (aesthetic); and most importantly, buy it when the store is in a sale (cheap)!

“True to the motto ‘form follows function, a well-designed curtain wall is only as good as its functions. I cannot think of any other building energy resources and ensuring we are protected from weather, noise, and other external factors. A well-designed envelope is not only important for our comfort, but it is also equally responsible for the heating and cooling loads we spend and the overall energy consumption.

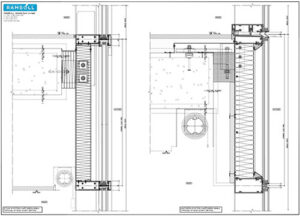

Susanna adds, “Considering these facts, I would change the question to a well-designed building envelope. A curtain wall system is usually pre-tested. We know the current performance standards the regional market offers, but how good is a curtain wall when the interface to the superstructure is faulty? How good is the interface when other trades are lacking coordination resulting in leakage and air infiltration? The interfaces to other building components are often neglected, thus we may split a well-designed envelope into two stages: the design phase and installation. In summary, I would say a well-designed envelope is the understanding and incorporating assembly and installation processes on and off-site between different trades”.

The Role of Glass in Curtain Wall Systems

According to Susanna, glass is undoubtedly one of the main components of curtain walling. It carries almost all the key aspects in its processing: safety, aesthetics, and thermal. Costs are mainly driven by the glass type and its required performance. One of them is the solar control coating which gives the glass its colour and shade. Reflectivity, internal and external as well as light transmission depend on this coating. Aesthetically, the quality of the glass processing gives the building façade the ultimate touch.

Characteristics of a Well-Designed Curtain Wall

• Performance: This is the basic function of a curtain wall, separating the interior of the building from the external conditions.

• Versatility: A well-designed curtain wall should be suitable for different conditions, and buildings, and provide a variety of solutions to different scenarios.

• Well-designed accessories: A well-designed curtain wall should incorporate accessories such as brie soles or louvres in a seamless way, which means without compromising the performance of the system.

• Installation: The design of a curtain wall should always consider the installation, panels, and brackets should be designed to ease the installation process at the site.

Many of you may have noticed distortion in one or the other skyscraper caused by the process when the glass is heat-treated, she adds. Another important consideration is the glass’s internal reflection which is often the least prioritised. We noticed a trend from architects and developers requesting to reduce the ‘glass’ internal reflections to enjoy views and sceneries, especially at night. We tend to recommend a glass coating internal reflection lower than 15%. We understand this is tough to achieve, especially when other coating requirements are prioritised.

Nevertheless, our Industry Partners are doing their best to invent new coatings to meet market demands. The essential factor of the glass, however, is safety; it serves as a falling height protection and human impact from the inside; on the other hand, we have to consider the post-breakage behaviour of the different glass types and the usage at higher elevations, eg. glass pieces falling on pedestrian ways or roads.

According to Fernandez, glass is the main boundary material between the inside and the outside of a curtain wall, glass gives us the possibility to see what is outside, provides natural light, and is separate from the weather elements, it also gives us thermal comfort or privacy when required. Apart from all these factors, the glass is also used as a way to express an architectural intent, an idea, or even an economical status. Glass fabricators in the last decades have provided a great range of glazing solutions that can combine performance and aesthetics in such way that the possibilities are almost infinite. Another relevant contribution of glass is its contribution to sustainability glass can help to reduce energy consumption and even produce energy by itself.

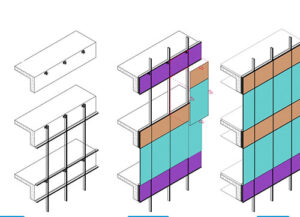

The Advantages of Unitised Curtain Wall

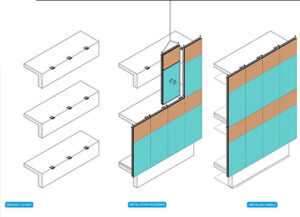

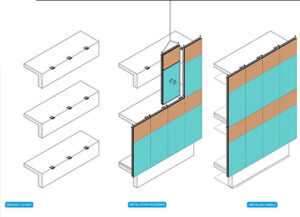

There are a lot of advantages to using unitised curtain walls, especially for highrise buildings. Sum believes that lots of people already pointed out most of them, such as faster production and installation, allowing differential movements, etc. All the fabrication and assembly operations are in a controlled environment. You have fewer people working on-site, and all of their activities happen on the floor slab – working on a cradle hanging outside a building is not required. “As safety matters to me and we are all responsible for our families, using a unitised curtain wall system to provide a safe working environment for our colleagues is the key advantage that I appreciate very much” he adds.

Susanna notes that the considerable advantage of unitised curtain walls is the efficiency of repetitive units and their installation. Once an assembly process is optimised off-site, the time saved on-site is significantly higher than a stick construction. Another decisive factor is the higher quality assurance due to fewer interfaces and workmanship on-site. Working at heights is moved to the inside of the building slab, and interior wall assemblies can be easily integrated. She prefers the unitised curtain wall rather than stick constructions because of these reasons. Of course, it will always be the first discussion if a stick curtain wall is equally suitable, especially when it comes to building movement joints.

A unitised system is better at accommodating movement joints and is more

One of the most evident advantages of the unitised curtain wall is the speed and ease of installation, typically A unitised system is installed around the same floor which gives the chance to the other parties to work on the inside of the buildings during the installation of the façade, this facilitates all the other works like MEP or internal linings. An important advantage, that sometimes is not considered, is the capacity of a unitised curtain wall to absorb the building movements, this becomes a crucial factor for high-rise building construction where building movements are considerable.

The Parameters for Designing a Curtain Wall System for a Building

As I mentioned above, if you think of the parameters of how you select a winter jacket – then you will not be too far away from getting a good curtain wall system”, says Sum. There are indeed a few more interesting parameters worth thinking about:

• Lightning protection: The curtain wall shall protect occupants against lightning strikes and not get an electric shock.

• Acoustic: You can have a peaceful room by isolating highway and party noises from your neighbours.

• Maintenance: Components that might break during their life span should be designed as accessible and replaceable.

• Warranty: Go back to the supplier and repair it when something goes wrong! Fernandez explains that there are several categories that need to be considered for the correct design of a Curtain Wall System:

• Structural: Loads will define the size and thickness of the curtain wall profiles, glazing, or other cladding materials, Typically to be considered are the wind load, dead load, and Live load among others.

• Geometry: Shape and modulation of the façade will also affect the design of the profiles and glass, Easily we can think about the differences between straight and curved panels, and modulation will affect the loads that the curtain wall needs to support.

• Aesthetics: Colour of profiles and glass appearance along with added accessories such as fins, blinds, decorative screens, and so on.

• Performance: The performance parameters are a driving factor in the curtain wall design, thermal performance (typically known as U-value) or water and airtightness will have key importance in the design of the systems.

• Fabrication/Logistics: Supply of materials and facility condition are fundamental factors in the success of the curtain wall design, the proper supply chain ensuring the quality of the received materials in place and time along with a well-implemented QA/QC system is of massive importance to deliver a good product.

• Site/Installation: Getting a good product to the site will not be enough to ensure the final success of the curtain wall, an experienced site installation team is necessary to achieve the final goal of a well-designed Curtain Wall.

Thermal Performance of Curtain Wall System

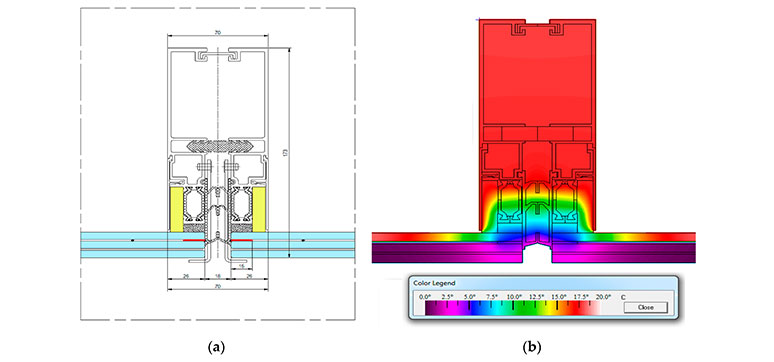

Sum points out that thermal performance is one of the essential criteria in the current curtain wall system design, considering energy saving and sustainability is some of the hottest topics that we cannot ignore. Glass panels generally have better thermal performance, the next challenge is to provide an excellent thermal break aluminium system to offer an excellent insulated façade. Susanna explains that the thermal performance of a curtain wall should be adjusted to its climate conditions. The trend is often to adopt the U-value of colder countries to tropical or as we have it here in the United Arab Emirates (UAE) hot and arid weather.

The U-value originated from the energy transfer through building materials from a high density of molecules to a lower density. The second rule of thermodynamics applies to this theory. It is an ongoing debate on how it changes the performance when cooling loads are calculated to keep the heat outside. Tropical countries usually have a temperate difference of ~10 degrees Celsius between interior and exterior while here in the UAE, we are fighting with around 25 temperature differences. The same is applicable in cold countries where the temperature delta reaches up to 30 degrees C. Tropical climate does not require a strict U-value and high shading coefficient.

What we like to do before we set the standards for a curtain wall performance is to look around the existing buildings and traditional architecture. It is not a secret to survive in harsh climate conditions. Human beings have adopted their living standards. In the Gulf Region, shading devices like Mashrabiyas, vertical fins, and small window openings are present in older building designs. Today, we try to adopt these principles with different materials and glass coating technologies to allow for higher design freedom,

Susanna adds. In tropical countries, windows and terraces are often shed with big and wide cantilevered canopies or roof extensions. The ultimate water and sun protection in one. At the same time, cold countries open their south façades to gain heat from the winter sun. Fernandez stresses sustainability. He says it is a key focus these days, building construction and the façade, in particular, cannot be indifferent to this, curtain wall design has to contribute to this important goal. Here is where the thermal performance of the curtain wall takes its part. The thermal performance of a curtain wall is defined by its U-value, This measure indicates the energy transmitted through the curtain wall, the lower the U-value the more efficient the thermal performance of the curtain wall. U-values requirements are clearly stated in the Energy consumption regulations the available façade technologies allow for improved U-values to achieve higher sustainability goals such as zero-emissions buildings.

The Challenges Associated with Curtain Wall Systems

There are many challenges in many aspects (technical, commercial, site coordination… etc.), but I can immediately think of the client’s expectation management. Our clients, especially in this region, are pushing the curtain wall system to be better, faster, and cheaper. While the industry is pushing our edges every day to make ourselves beyond the boundaries, we need to manage the client expectation and make it ‘slightly’ more realistic – and we have to do that: don’t give fake promises to your client” says Sum.

According to Susanna, the biggest challenge that is faced by a consultant is convincing the client of the best performance and the best suitable system of a curtain wall design which may exceed the investment cost but has a higher return. These figures are not tangible at the first moment; however, we see that better quality is a long-term investment. Historically, the construction pressure has been enormous to finish projects on time or ridiculously planned site programmes where installation quality has been the most significant compromise. This is tangible now with the many requests we receive for operational and unfinished buildings where the curtain wall leaks water and air. This, she believes, is one of the biggest challenges associated with curtain walls and their precise installation period. This convention of understanding this long-term damage for the developers’ protection and money-saving escalates quickly to long and in-depth discussions.

Fernandez points out that energy efficiency is one of the main challenges for the façade industry and the design of the curtain walls, in particular, there are several strategies implemented to achieve better energy performance, we can classify them into two main groups, active measures like PV glass panels or Bio-energy façades that can produce energy by themselves and the passive measures like low-E glass coatings or the use of triple insulated glass units to reduce the U-value, other alternatives are the shadings like the ones mounted on kinetic façades or the design of active curtain walls where the stack effect is used to improve the thermal performance.

The Most Common Types of Failures in Curtain Wall Sections

According to Sum, the most common type of failure is air/water leakage through the curtain wall systems. If the system is tested, then the design should be fine overall, and the remaining potential issues may come from fabrication and (most likely) installation. That is why having skilful labour and a professional supervision team is very important to have a successful curtain wall package. Susanna opines that the right alignment of the weather membrane and the allowance for tolerances and movement of a bracket is something we have to reject on 90% of our site visits. The design drawings and approved shop drawings do not reflect the actual site conditions and therefore adjustments to slabs and brackets are nearly always the case. Thankfully it is spotted in the early stages and rectification can happen accordingly.

Fernandez explains, in many other fields, the devil is in the details, a typical curtain wall wins just spandrel panels, and vision glass will be very robust and unlikely to present failures if it has been fabricated and installed as per the industry standards. When the requirements of the curtain wall design are higher due to the building complexity or the required performance, failures can appear if the design has not been done carefully. Common types of failures are the ones related to the performance of the curtain wall like air/ water leakages due to penetrations on the seals or incorrect installation and the ones related to the building movements and tolerances where the curtain wall cannot accommodate the building movements like sway or drift.

Latest Technologies in Curtain Wall Systems

There are a lot of new technologies to curtain wall system development. But it is my interest (and we are working on it very well right now) – we are combining the entire design flow (from concept to shop drawings to fabrication) into a single model, says Sum. “The ‘traditional’ BIM model contains many building information. However, in our curtain wall industry, the model is neither describe the geometry precisely nor detail enough to produce fabrication drawings; we regard it as just for “entertainment” only.

Thanks to our core programming team’s coding capability, we make the script to describe the building geometry and then apply all the details and fabrication data into the model – the fabrication data is then automatically generated from the script. Using this method, we are significantly saving a lot of time in fabrication drawing preparation and eliminating human errors – we call it FIM: Fabrication Information Management, he explains.

According to Susanna, the latest trend is dominated by these two materials – hand glass treatment and building automation. It is good to see that end-users and owners are aware of the comfort and sustainability aspects of a curtain wall design. The push towards automation and better-performing building envelopes is initiated by local authorities and the more prominent presence of sustainability experts. “I would call it a trend – a positive one – where clients request building simulations with different scenarios to choose the best options.

Parametric modelling makes this easy to run other options and compare the results. Our team has been involved in many discussions where cooling loads and shading designs were presented with a wide acceptance to increase the building envelope’s performance”. The desire to integrate façade openings or adjust the room daylight and shading conditions via smart devices is becoming famous. We see a drive towards changing glass transparency, especially for private residences – the coatings on the glass allow the interior’s darkening without external or internal blinds. It is a significant change evolving and consulting our clients with the latest trends and possibilities. We can consider two main trends regarding the latest technologies applied to the design of curtain walls, The first trend is the use of new materials and the other is the use of parametric tools for the design and fabrication of the curtain walls, says Fernandez.

As new materials, we can mention the use of composite materials such as carbon fiber or GRP profiles, electrochromic glass, or compacted stone claddings. Parametric design has opened a whole new world of design possibilities allowing curtain wall designers to come across an architectural design that was not possible 20 years ago.

Parameters That Decide The Success of a Curtain Wall

Curtain walls, just other projects, need everything to be well done to be claimed as a curtain wall’s success. But if any single parameter that we mentioned before is failing or could not meet the expected performance, it is a total failure, says Sum. It is just a jigsaw puzzle, you need all the puzzles put together to complete work. Missing any single piece, although it is tiny, is incomplete and should be regarded as a failure.

“In summary, I would say that performance is only given by its proper function, adoption of local market conditions, consideration of site installation processes, and the ability to allow flexibility within the design process to react faster to changes”, says Susanna.

Coming back to the introduction statement with the ‘Form follows function, façade consultants should adopt the statement ‘Performance follows function’. The curtain wall performs only in its designed purposes. Functions are something that is fabricated, assembled, installed, and maintained for its purpose. To give an example think of your car or smartphone – they will only perform at their best when all of the components are functioning together and well maintained – long road trips will be enjoyed comfortably without breakdowns.

Fernandez explains, that for a successful design of a curtain wall, some factors are essential at the different project stages, During the design stage, the knowledge and use of the latest technologies such as parametric design BIM integration are key for the success of the project, a strong technical team is a great asset for a curtain wall design. During the fabrication stage, a well-implemented QA/QC process is completely necessary to achieve the required level of quality for a curtain wall. Finally, during the installation of the curtain wall, counting with an experienced site team and the proper management will ensure the success of the curtain wall.

Criteria to Select between Stick and Unitised Systems

Sum stresses on two most important criteria to choose between stick and unitised systems: • Do the panels are highly repetitive and can be done massively in the factory? – If yes, go for using the unitised system • Does the panel need to allow big differential movement between supports? If yes, go for using the unitised system. A decision between both is often not easy. It depends on architectural design and how complex and high a project is. The main criteria are based on the design pattern and the location of the building. In Europe, towers are often designed as unitised because the workmanship is a higher cost than in this region, says Susanna.

Weather and site conditions are the main drivers. Another factor in planning is the repetitiveness of the surface. Are balcony slabs or setbacks in the building complicating the reach and the installation? Are the assumed building movements possible with a stick construction and is structural glazing a requirement? These initial questions will narrow down the options to further evaluate cost impacts and efficiency. The project’s location is vital to understand whether a qualified installer and factories are at a reasonable distance to provide technical expertise. On-site and off-site assemblies have both their advantages and disadvantages.

Building changes can be accommodated within a stick system onsite that is easier than a unitised panel. Once the panel is assembled brackets and slabs have to be accurate in the designed position to receive the pre-assembled bracket while a stick profile can be adjusted. Generally, for a continuous application spanning over several floors, a unitised system is the preferred choice.

According to Fernandez, there are several considerations to take when selecting between a stick and a unitised curtain wall, the more common ones are the following:

-

- Budget: There is a difference in cost between Stick and unitised, this is typically reflected in low-budget projects where the stick system has this advantage versus the unitise, this price difference is getting reduced by the implementation of new technologies that expedite the design and fabrication process.

- Building configuration and shape: As commented before the shape and size of a building can determine the type of curtain wall to be installed, for example, a unitised system will have much more of an advantage on a high-rise building with a large level of repetition, otherwise, a stick system will be more suitable for a podium with a complex design and low level of repetition.

- Performance: There are considerably better performance and quality levels of a unitised system versus a Stick system that relies on the site workmanship for the correct installation, There is a higher number of failures on a Stick system compared with a unitise one.

- Time constraints: For some projects, it is important to have material installed on-site as soon as possible due to time and commercial reasons, that gives an advantage to the stick system cause normally they are “by the self” and the materials can be obtained faster, on the other hand, a unitised system will help to close floor by floor much faster and allow for other parties to work in the building interior.

He adds, all these factors have to be considered and analysed during the early stages of the design to choose the most suitable solution, as changes in systems at more advanced stages normally lead to a problematic and unsuccessful project.