Green or living walls are becoming a familiar feature of the built environment. Whilst their relevance to sustainability and net-zero might not be clear they do present a public statement of green intent and do benefit city biodiversity, air purity, thermal environment, noise, and no doubt mental health. With all of these benefits, whilst possibly unpopular, there is a need to consider the challenges that their introduction creates for the safety and insurability of the building they are deployed on.

Once included as small decorative areas on buildings, they are now proposed for much greater expanses, covering an entire side, or even every side, of tall buildings, and perhaps this best explains the current raised level of interest in addressing their potential fire implications. Building life safety is normally well addressed within our regulations, but on green walls, there are inconsistencies between ADB and other government guides, and the allowance of a 2-track system for compliance enables them to incorporate materials and be tested in a way that would never pass muster in a normal façade system for certain building types which, in this post-Grenfell era, seems both wrong and completely counter-intuitive.

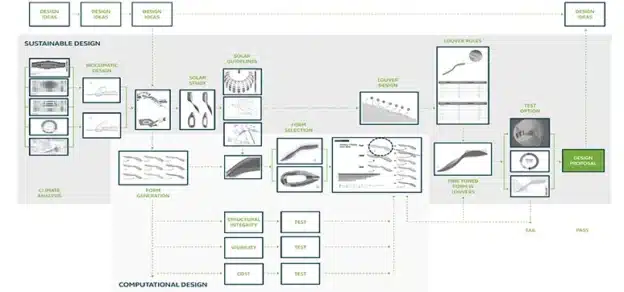

In my view, there is an obvious need to stop thinking about green walls as anything except another form of cladding – the outmost layer of a façade system. Building façade engineering is an involved and increasingly complex area that demands very specific expertise to ensure its whole-life performance, meeting stringent requirements for weather protection including wind resistance, thermal efficiency, acoustic performance, light transmittance, security, lifespan, and of course fire safety. Engineering detailing and installation accuracy is paramount, and many organisations, assurance and product certification schemes, exist to promote quality.

A typical rain-screen type façade system is a kit-of-parts comprising innermost, the building’s structure that supports it, layers of insulation, membranes, a cavity for moisture and air pressure management, and outermost the building’s skin – the visible cladding which might normally be formed of masonry tiles, metal composite sheets like ACM, or a myriad of other options, can now include green walling.

Horizontally mounted open-state cavity barriers within the façade’s cavity are designed to close under the action of fire to seal against the rear face of cladding panels to prevent vertical spread, and horizontal spread is restricted by the placement of vertical closed-state cavity barriers. Green walling systems come in different configurations, but a not uncommon current design employs plastic planting modules filled with growing medium, the plants, and an associated irrigation system (plastic pipe and guttering). Now visualise a rain-screen system where the outermost cladding panels are replaced by the green wall system, and you soon realise where the challenges lie:

• The cavity within the façade is now bounded by the insulation (which might be plastic) and the plastic of the rear of the potting system (without even the metal sheet protection afforded by an ACM), a situation that has the potential to support fire spread at a rate greater than open-state cavity barriers may function, effective cavity closure against the often uneven profiled back of the potting system might be almost impossible and closure against combustible materials needs very careful consideration,

• Any profiling of combustible materials within the cavity surface acts to increase the available fuel load above that of a flat surface, and

• The fire spread up the planted vegetation.

Approved document B cites that the external walls of buildings, with respect to green walls, should meet the performance criteria of full-scale façade testing as described in BR135 using the BS 8414 test methodology, a demanding 8+ metre test with full room flash over fire simulation of 3.5 MW heat output, used for all façade systems; or the green wall ‘best practice fire safety guidance document, Fire Performance of Green Roofs and walls, published by DCLG in 2013.

By comparison, the best practice guide establishes fire suitability for the whole system from the small-scale Single Burning Item (SBI) test of EN 13823 (1.5 metres high with a fire heat output of just 30 kW), a test more normally used for single materials with flat surfaces.

Of the two options one is clearly much more demanding than the other and the use of SBI can be easily criticised for its small fire challenge and front-face-only fire application where the problems of fire spread within a combustible cavity (the greatest threat) are unlikely to be revealed at that heat output and on that timescale. I have observed enough BS 8414 tests to know that the fire is severe enough to always challenge the cavity and its contents even if the cladding is fully non-combustible. Those who recall the issues in the 1980s with combustible sandwich panels used in the food industry, know how inappropriate small-scale testing (the cone calorimeter in this case) can promote products and give false assurance to building systems that behave disastrously at full scale (later sorted out by insurers introducing the large scale LPS 1181 test that allowed sandwich panels to delaminate and spill their contents under fire at full span).

The front-face protection afforded by the soil and plants is obviously greatly influenced by irrigation, plant selection, and the presence of water and this alone introduces some interesting considerations:

• No other product standards allow performance to be assessed wet for the simple reason that at times, they might not be wet. Is this an abuse of BS EN 13501-1? what if a request came along to test other building products with a wet flannel draped over them?

• If the safety of the building and its occupants is linked to the correct function of the irrigation system, then by default it becomes a life-safety system in its own right and needs to be designed, installed, and maintained as such. For guidance on what it takes to make water supplies resilient, a good starting point is the LPC Rules for Automatic Sprinkler Installations – it is not a trivial or cheap matter,

• Should the green wall ever dry out, is the building safe to use and occupy? A question for Building Control and the Fire Service,

• Is a test that can be passed or failed based upon the species of living vegetation used a good test?

Just as failures are caused by the alignment of many poor factors (the Swiss cheese model), the same applies to the correct operation of the systems designed for protection – a green wall installation justified on the grounds of the SBI apparatus alone must always be as wet, AND always have the same plants, AND those plants must always be in the same healthy condition, AND the presented fire must not be greater than 30 kW, AND fire must never enter the cavity, AND fire must not start in the cavity (i.e. kitchen vent), etc. With every additional requirement, the aggregate probability of safe function reduces – you start to quickly appreciate why insurers favour non-combustible materials – they have few other dependencies to perform.

Just as failures are caused by the alignment of many poor factors (the Swiss cheese model), the same applies to the correct operation of the systems designed for protection – a green wall installation justified on the grounds of the SBI apparatus alone must always be as wet, AND always have the same plants, AND those plants must always be in the same healthy condition, AND the presented fire must not be greater than 30 kW, AND fire must never enter the cavity, AND fire must not start in the cavity (i.e. kitchen vent), etc. With every additional requirement, the aggregate probability of safe function reduces – you start to quickly appreciate why insurers favour non-combustible materials – they have few other dependencies to perform.

I must confess that it is not clear to me why green walls have been afforded special consideration within Building Regulations. If treating them as cladding systems, excludes their use, one can only assume that the government is prepared to make compromises to safety to make buildings and cities prettier.

So how will a green wall system of the plastic pot type fare when subjected to the BS 8414 test? To a certain extent, this can be answered by a recent ‘worst-case’ experiment funded by AXA Insurance at the Fire Protection Association’s facilities in Moreton-in-Marsh. The material components of an unplanted (no soil or plants) green wall system that, as a planted system achieved a B-s2 d0 fire rating, were subjected to the BS 8414 fire load with a 5m high sample on one face of the test rig.

The tested components included the aluminium mounting rails, irrigation system (not water-charged), and guttering system. Whilst it is certain that there would be differences in the reaction of the front face if planted up, as plant material dries and burns off and growing medium dries, the likely involvement of the unprotected plastic in the cavity and associated plastic pipes and fittings remains valid. At the very least the configuration is relevant to an ‘under construction’ scenario.

If the system installed was compliant with the full requirement of BS 8414 it would not surprise the reader that the system would fail to meet the requirements of BR135, failing on the grounds of both internal and external fire spread, with the size of fire limited only by the amount of system installed. In under 5 minutes, the plastic had burned out completely to the full height of 5 metres above the crib and proceeded to burn laterally. The fire was extinguished soon after.

So, two systems of appraisal that might (subject to establishing the extent of protection afforded by wet soil in the BS 8414 test) give different results – this clearly needs some thought. When testing gaseous fire protection systems there are a number of tests that can be used for the determination of the ‘extinguishing concentration’. These vary greatly in scale from bench-top equipment to large rooms, but the standards state that the value determined at the largest scale will prevail and even then a large safety factor is applied to give the end-user ‘design concentration’ – something similar could be specified for green-walls, but what would that mean for systems installed on the grounds of SBI data, if a future BS 8414 test might give a different result? (Are we removing cladding again?)

Like any insurance company, before providing cover for a building, AXA needs to make a judgment on how the prospect will perform in a fire event. Many names and versions are used but the key metric is Estimated Maximum Loss, or EML. This describes the most that are likely to be lost to a single fire event and considers the key routes for mass fire spread: through the occupied compartments of the building, through hidden voids, and over the external surfaces.

Grenfell and other large cladding fires demonstrate how the poor choice of external coverings can communicate fires to all floors and compartments readily – a situation that defeats all internal active and passive fire safety measures. A building with a high EML may present challenges in terms of availability, ease, and cost of insurance. Nick Tilley of AXA Insurance states “Early and detailed engagement with insurance risk engineers and underwriters is very important so all aspects of project design including resilience to wind as well as fire can be fully reviewed. This needs to include the robustness of monitored irrigation systems and any backup to ensure the plants remain healthy plus the ongoing maintenance of both the plants and the irrigation system”.

Other versions of green walling do of course exist, and great effort has been made to remove all combustible content (aside from the plants themselves) by others including Vertical Meadow. Originally a façade engineer from ARUP, Alistair Law has developed a hydroponic aluminium cassette system that grows the plants in a non-combustible medium. “The events at Grenfell profoundly impacted me as a façade engineer, hence fire and biodiversity enhancement were non-negotiable requirements when we started designing our living wall cladding panel. I recognise the remaining fire spread limitations; however, I believe this can be addressed in the configuration by good design principles.

Getting this right safely is essential in restoring biodiversity to our cities and planet, there is a lot at stake for everyone.” The cassettes that replace the cladding have a flat back, are a suitable surface for open-state cavity barriers to seal against, and introduce no additional combustible materials into the all-important rain-screen cladding void. There’s still the issue of fire spreading up the plants to deal with, a not inconsiderable remaining challenge that might demand the use of forestry-like fire breaks, but it’s certainly a step in the right direction for reducing the number of combustible materials on buildings. It is understood that non-combustible versions (metal) of the soil potting system format tested are also available or proposed.