India is the second most populated country in the world with nearly a fifth of the world’s population. According to the 2017 revision of the World Population Prospects, the population stood at 1.339 billion. Infrastructure and industries tend to increase by meeting population demand and growth, which will considerably increase the energy demand. Therefore, it would be essential to reduce the energy per capita to meet the demand of the increased population. It’s also essential to reduce the carbon footprint and to preserve the environment.

Substantial infrastructure has been developed across India to meet the demands of the growing population. Bengaluru is one of the best examples of development with an increase in population. In this article, we shall be going through how the selection of glazing can play a significant role in the reduction of thermal and energy consumption.

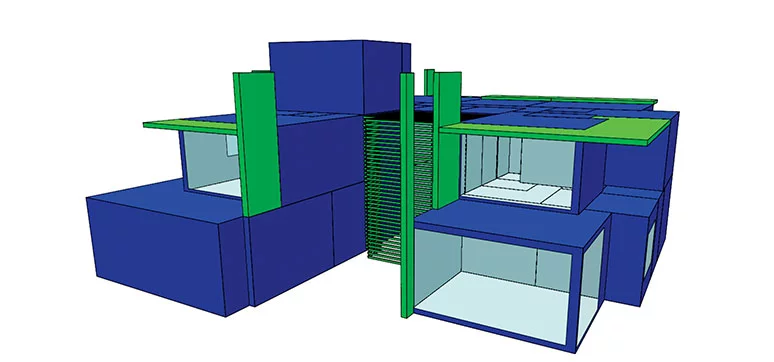

An energy model has been developed for the prototype villa to perform energy Simulation and study the impact of savings. In this example, we have assumed a G+1 Villa with 4BR located in Bengaluru and studied the impact of the reduction of thermal and energy reduction.

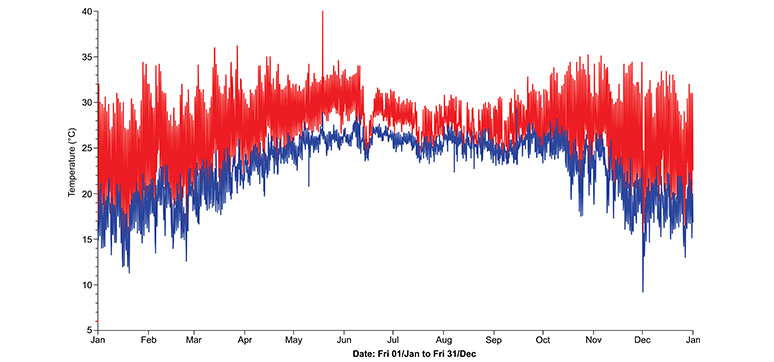

Bengaluru climate has been categorised as Zone 1 as per ASHRAE 90.1 which is defined as Very Hot-Humid (1A) and Dry (1B). The graph above (Fig. 1) summarises the dry-bulb and wet-bulb temperatures of Bengaluru.

A building envelope is a physical separator between the conditioned and unconditioned environment of a building, including the resistance to air, water, heat, light, and noise transfer.

A thermal envelope is one of the key elements of a passive or low-energy house. The most important parts of the thermal envelope include outer walls, roof, foundation, windows, and doors. The purpose of the thermal envelope is to prevent heat transfer from the interior of a house to its exterior in the winter and vice versa in the summer.

Most villas are designed to have 20 to 40 per cent window-towall by taking into consideration the architecture and daylighting aspects. Selection of suitable glazing by taking into consideration architectural parameters could benefit the occupants during operation.

Prior to the start of the design, it is essential to focus on the orientation and distribution of the window-to-wall ratio (WWR). Following are the few points to be considered during the concept stage of the project:

Adjusting the window-to-wall ratio (WWR) of the building envelope affects the amount of heat entering a space. The lower the WWR, the better the Envelope Thermal Transfer Values (ETTV).

Provide glazing where it is effective for views and/or daylight. Avoiding heat gains can be addressed by creative glazing design, which should vary as a function of the orientation.

Façade orientation should influence WWR. A north-facing façade receives the least solar exposure and should have the largest glazing area. ASHRAE energy modelling guidelines penalise the building (by reduction of energy savings) if the WWR percentage is more than 40 per cent. Hence, WWR should not exceed more than 40 per cent.

In general, the selection of glazing depends on architectural appearance and cost, instead of focusing on the thermal properties of the glazing. This article focuses on the relationship between the U-factor and solar heat gain coefficient (SHGC) in relation to solar gain.

Thermal energy is an example of kinetic energy, as it is due to the motion of particles, with the motion being the key. Thermal energy results in an object or a system having a temperature that can be measured. Thermal energy can be transferred from one object or system to another in the form of heat.

Due to the increase in temperatures, HVAC is becoming part of our life for thermal comfort. Hence, minimisation of thermal gains into the building could reduce energy consumption. Solar gain is defined as solar radiation absorbed on the internal surfaces of the room, plus solar radiation absorbed in glazing and transferred to the room by conduction.

The analysis is performed by considering the different U values and SHGC values.

Definitions are these parameters are as follows:

Thermal transmittance (U-factor): Heat transmission in unit time through unit area of a material or construction and the boundary air films, induced by the unit temperature difference between the environments on each side (W/ m2K), in IP units it is referred in (Btu/h·ft2.oF).

| Items | Baseline Case | Parameter 1 – U value 4.5 W/m2K, SHGC 0.25 |

Parameter 2 – U value 3.5 W/m2K, SHGC 0.25 |

Parameter 3 – U value 2.5 W/m2K, SHGC 0.25 |

Parameter 4 – U value 2.5 W/m2K, SHGC 0.22 |

Parameter 5 – U value 2.5 W/m2K, SHGC 0.20 |

| Wall | 0.705 W/m2K | 0.705 W/m2K | 0.705 W/m2K | 0.705 W/m2K | 0.705 W/m2K | 0.705 W/m2K |

| Roof | 0.360 W/m2K | 0.360 W/m2K | 0.360 W/m2K | 0.360 W/m2K | 0.360 W/m2K | 0.360 W/m2K |

| Floor | 0.363 W/m2K | 0.363 W/m2K | 0.363 W/m2K | 0.363 W/m2K | 0.363 W/m2K | 0.363 W/m2K |

| SHGC | 0.25 | 0.25 | 0.25 | 0.25 | 0.22 | 0.20 |

Table 1: Analysis 1 – Impact on overall heat gain

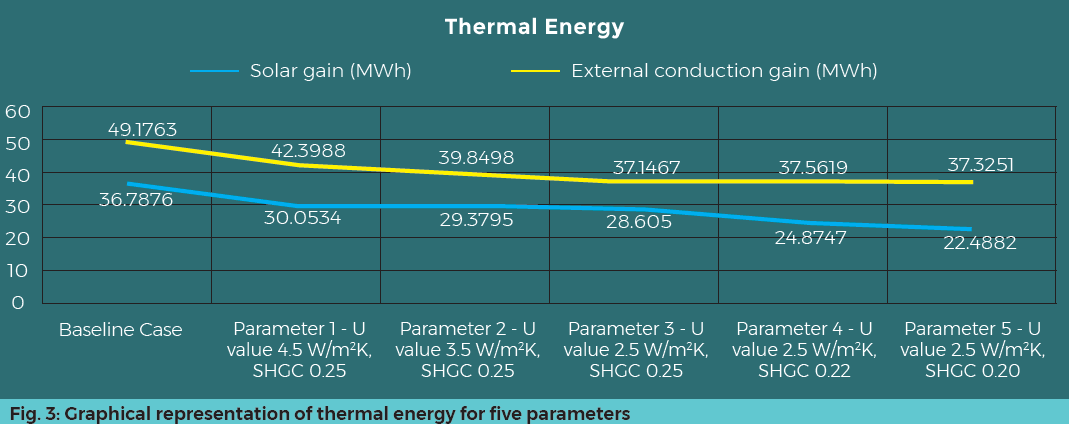

| Parameter | Solar gain (MWh) | External conduction gain (MWh) |

Heat gain (MWh) | Percentage difference |

| Baseline Case | 36.7876 | 49.1763 | 85.9639 | |

| Parameter 1 – U value 4.5 W/ m2K, SHGC 0.25 |

30.0534 | 42.3988 | 72.4522 | 15.72% |

| Parameter 2 – U value 3.5 W/ m2K, SHGC 0.25 |

29.3795 | 39.8498 | 69.2293 | 19.47% |

| Parameter 3 – U value 2.5 W/ m2K, SHGC 0.25 |

28.605 | 37.1467 | 65.7517 | 23.51% |

| Parameter 4 – U value 2.5 W/ m2K, SHGC 0.22 |

24.8747 | 37.5619 | 62.4366 | 27.37% |

| Parameter 5 – U value 2.5 W/ m2K, SHGC 0.20 |

22.4882 | 37.3251 | 59.8133 | 30.42% |

Table 2: Overall heat gain which is the combination of solar gain and external conduction gain has been analysed by changing the U values and SHGC.

Solar heat gain coefficient (SHGC): The ratio of the solar heat gain entering the space through the fenestration area to the incident solar radiation. Solar heat gain includes directly transmitted solar heat and absorbed solar radiation, which is then re-radiated, conducted, or convected into space.

The relationship between the thermal transmittance and solar heat gain coefficient has been studied in the following analysis and the impact has been presented. For the purpose of analysis, the U values and SHGC of different fenestration of glazing are considered whilst the rest of the inputs are kept identical in all cases.

Five options have been considered comparing with the ASHRAE 90.1 baseline case and further enhancement to the U value and the reduction of SHGC. Kindly note that this article focuses only on the enhancement of fenestration whilst the rest of the parameters are kept identical. Table 1 exhibits the assumptions considered in each simulation.

Overheat gain which is the combination of solar gain and external conduction gain has been analysed by changing the U values and SHGC. The analysis considered all of the five parameters by comparing them with the ASHRAE 90.1 baseline (Table 2, Fig. 3). The selection of efficient glazing could significantly reduce the heat gain which could maximise more than 30 per cent.

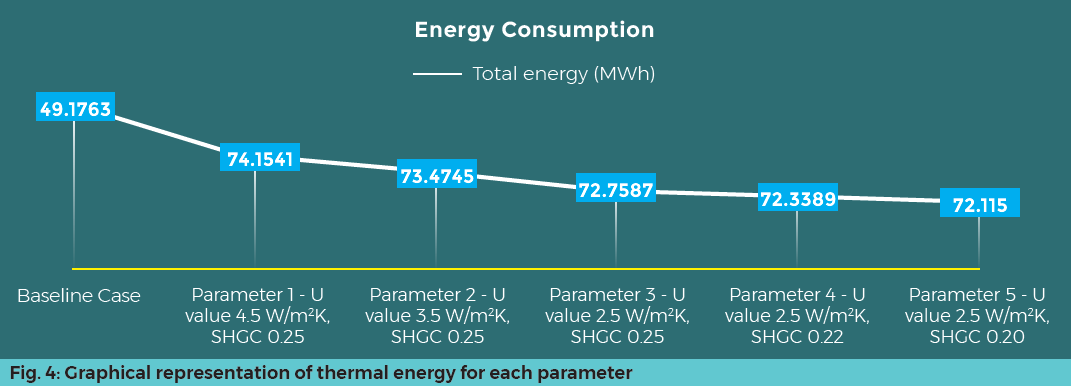

| Parameter | Total system energy (MWh) |

Total lights energy (MWh) |

Total equip energy (MWh) |

Total energy (MWh) |

Percentage Difference |

| Baseline Case | 60.6327 | 11.04 | 4.8492 | 76.5219 | |

| Parameter 1 – U value 4.5 W/ m2K, SHGC 0.25 |

58.2649 | 11.04 | 4.8492 | 74.1541 | 3.09% |

| Parameter 2 – U value 3.5 W/ m2K, SHGC 0.25 |

57.5853 | 11.04 | 4.8492 | 73.4745 | 3.98% |

| Parameter 3 – U value 2.5 W/ m2K, SHGC 0.25 |

56.8695 | 11.04 | 4.8492 | 72.7587 | 4.92% |

| Parameter 4 – U value 2.5 W/ m2K, SHGC 0.22 |

56.4498 | 11.04 | 4.8492 | 72.3389 | 5.47% |

| Parameter 5 – U value 2.5 W/ m2K, SHGC 0.20 |

56.2258 | 11.04 | 4.8492 | 72.115 | 5.76% |

Table. 3: Total energy changes consumptions by changing the U values and SHGC

As the SHGC value decreases, proportionally the solar gain is reduced. This exercise can overview the importance of selection of lower SHGC values and it has a major factor in reducing the overall solar gain.

Analysis 2: Impact on Total Energy Consumption

Overall energy is the combination of system energy, lighting energy and equipment energy. The analysis was considered on all five parameters by comparing them with the ASHRAE 90.1 Baseline. Total energy changes consumption by changing the U values and SHGC are presented in the following table (Table. 3), as it is noted that massive amounts of energy savings are demonstrated by the selection of efficient glazing.

Conclusion:

Reduction of U value and SHGC plays a significant role in the reduction of the overall energy and thermal energy and likewise similar increase could have an adverse effect on the building energy consumption.

Glazing parameters should be reviewed in detail prior to the finalisation of fenestration. It is very important that test conditions are considered prior to selection, the following are a few guidelines that could assist in the selection of glazing,

The “Overall U value” should be considered not the centre of the glass. In general, the U value at the centre of the glass is more efficient compared with the overall U value. Data sheets should be reviewed to obtain these details.

U value should be analysed by including the frame i.e., not only the glass but also should include the assembly. Several software are available in the market that can perform the analysis.

- Testing should be in accordance with the following listed standards or equivalent whichever is efficient,

- U value should be in accordance with NFRC 100

- SHGC should be in accordance with NFRC 200 and

- Visible transmittance should be in accordance with NFRC 200.

- Visible transmittance should balance by considering daylighting and security.

If the project has a minimal budget, then the focus should be on the areas that have the maximum solar exposure and installing the building in a west-facing orientation.

Daylight & Views: –

Good daylighting not only reduces the artificial lighting load of a building, but it also reduces the heat gains from artificial lighting, and therefore the ventilation or cooling load. It is therefore important to understand the effect of glazing on the energy performance of buildings by performing the simulation during the concept design stage.

Daylight and occupancy sensors can be used to reduce or turn off electric lighting automatically when it is not required. In new offices, the glazing ratio (the area of unobstructed glass as a fraction of the total wall area) should not exceed more than 40 per cent.

Providing glazing from floor to ceiling is not the most effective way to provide views as it will also bring in more solar radiation. Vision glazing is typically applied between 750 mm and 2,100 mm to accommodate sitting and standing occupants. Areas below 750 mm, therefore, do not require glazing for either daylight or vision purposes. This can save on material costs and also reduce the amount of solar radiation entering into space through the glass.

The Balance between SHGC and Visible Transmittance

Windows that reduced solar gain (with tints and coatings) also reduced visible transmittance. However, new high-performance tinted glass and low-solar-gain low-E coatings have made it possible to reduce solar heat gain with little reduction in visible transmittance. It is measured in the Light-to-Solar Gain (LSG) ratio.

- In hot climates, high LSG means good heat rejection with minimal impact on view and daylight.

- The LSG ratio is defined as a ratio between visible transmittance (VT) and solar heat gain coefficient (SHGC).

- A clear double-glazed unit with a low-solar-gain low-E coating (H) reduces the SHGC significantly, to 0.25, but retains a relatively high VT of 0.70, so the LSG is VT/SHGC = 2.80