Balustrades are all around us, and thankfully so in most cases. They are so ubiquitous that we take them for granted. They are present even in the simplest buildings and have been there for centuries. Think of an old-fashioned balustrade, and you will probably think of an old stone type, with the curved, and ornate baluster posts. Three aspects of these old designs are immediately apparent – they provided protection, they provided a view, and they were elegant. (The word baluster comes from the Greek balaustion meaning ‘wild-pomegranate flower’).

In modernity, this type of balustrade has frequently been replaced by one incorporating glass – all adequately providing the same function. But beware, for an element so common, their designs are surprisingly frequently inadequate – particularly in terms of their end functions. Arguably the simplicity and familiarity are the reasons for the mistakes made. So, let’s break this down – firstly by function, and then by components – hopefully revealing some of these overlooked issues along the way.

Function

Aesthetics are important, but in the case of a balustrade, the functions are more important. Balustrades are only installed if there is a functional reason for them to be present. Functional failure of a balustrade can be catastrophic and can even result in multiple fatalities. The principle function of a balustrade is to provide protection from a hazard, most frequently from a fall. However, there is also separation – the subtle difference being that one of the purposes of the balustrade may be to guide rather than to protect – perhaps in a queue or directionally on a stair.

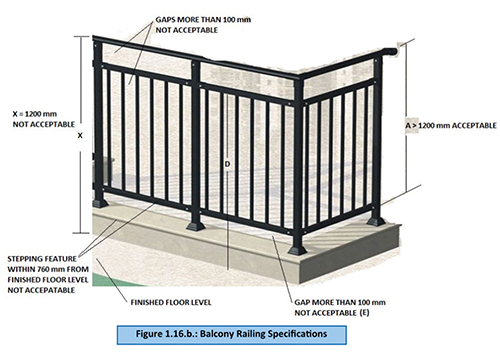

It may be important for a balustrade to allow ventilation, or conversely act as a wind break or a shield. Its purpose may be to provide privacy, or alternatively a view. And of course, its aesthetics must reflect the context of the building. Glass in balustrades, usually when combined with other elements, provides an excellent (if not unique) material to meet all the desired criteria. There are some important particular characteristics that ensure the typical minimum protection performance. The most obvious is height – most commonly this is 1.1m from FFL (finished floor level) but higher in some jurisdictions. (It is also worth noting that the sill of a window becomes a balustrade, when the window is fully-opened.)

Generally, openings in the balustrade should not be such that a 100mm diameter sphere would pass through them (a dimension that is related to the size of an infant’s head). It should not be readily climbable – a barrier that is also a ladder provides little protection where the young or (mis) adventurous are present. The practical combination of the non-climbability rule with the height rule is often overlooked. The regulated height may have to start from a climbable feature, which means the actual height is much higher.

Naturally, the balustrade should be able to resist the required load, usually the people-load and the wind-load. These can vary depending on the application, and both codes and standards provide clear guidance on these (BS and ANSI are good examples). The most common mistake here is that the appropriate safety factors are either not applied, or applied improperly for the appropriate load type. Other frequently-missed loading-related aspects include post-breakage safety and capacity, fixing methods, stress concentrations, handrails, and the thermal environment; but now we are getting into the realm of how the components behave, so let’s look at those.

Components

The most significant component of a glass balustrade is, not surprisingly, the glass. The glass can be a panel within the system or the whole balustrade.

Glass selection in any aspect of construction is more complex than it appears. Glass has numerous characteristics, and modifying one of those often has an effect on another, including cost. As such, choosing the appropriate glass is an optimisation process. For the glass used in balustrades, three characteristics are considered to simplify the selection, which includes – safety glazing, post-breakage safety and (in the Middle East in particular) the solar / thermal environment.

Annealed glass and heat-strengthened glass, in their monolithic form, are not ‘safety glasses’. The former (annealed) is susceptible to the thermal cracking in the Middle East in any case.

Fully tempered (FT) glass is a safety glass, but if it shatters – it offers no post-breakage capacity. It is also susceptible to spontaneous breakage from Nickel Sulphide (NiS) inclusions, and minor damage often results in the whole pane shattering. For these and a few other reasons, laminated glass is essential – at least two layers of glass bonded to a plastic interlayer (which is usually a soft and flexible PVB but can be provided in a harder, less flexible ‘structural’ form).

This offers some post-breakage safety in the event of one pane breaking. FT glass, although the strongest kind of commonly-available architectural glass, loses all its structural integrity on breaking (in addition to its NiS issue). Consequently, where loads allow, we tend to use heat-strengthened laminated glass as our configuration of choice in the Middle East.

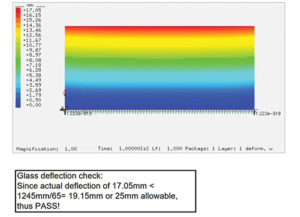

Where a higher design load necessitates the use of FT glass, a structural interlayer can be used, providing post-breakage support. However, this still does not fully alleviate the NiS problem. Once everything is in place and considered, a common (perhaps conveniently) overlooked issue is to consider an environment of 50°C when evaluating the structural performance. The various plastic interlayers available behave quite differently at that temperature, compared to the more frequently used 20°C.

Our next components are posts, rails, brackets and fixings. These may be the principle structural elements, such that the glass is only an infill panel, or there may be a structural collaboration between these and the glass. In glass terms, though, the stresses within the glass at the points of connection to the fixings, based on the fixing arrangement, are often the critical aspect. Speaking of stresses, turning our attention to the base channel, we find two issues that we should vigilantly watch out for. The first is the differences between calculation and reality. Many calculations assume a uniformly distributed load, indicating that the base channel captures the glass evenly along its length. The associated stress profile may look like this.

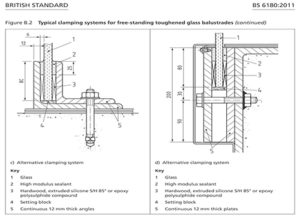

The reality may be that the glass is actually fixed in particular locations with wedges, packers, or bolts. Consequently, the actual stress pattern may look much less even, with hot-spots that hadn’t been predicted in the calculation. This can be a function of improper workmanship on site, where the designers have intended an installation in one way and the site team has built it in another way, incorrectly packed and adjusted it, or just installed it ‘how they have done it before’. The second watch point is related to the first and is highlighted in BS 6180.

The figures extracted from the standard show high modulus sealant used (2) with non-continuous packers (3) and inserted at particular locations for alignment. The combination provides an effective distribution of stress along the base. What often happens is a (less expensive) low-modulus weather seal is used – the consequence being that the stresses are transferred more locally into the packers, causing point loads not anticipated by the designers and not represented in the calculation.

An alternative may be to use grout, which sets to provide an even contact with the glass, and then a weather seal can be used to cap it off. This may not be possible if the balustrade is not horizontal. Our final component of note is the handrail, and there are as many questions as there are configurations.

• Does it contribute to the structure (has that been modelled)?

• How is it connected to the glass and how does the load, therefore transfer (stresses at the connection points)?

• How many panels is it connected to (it should be more than one – preferably at least three)?

• Is it protecting you from the glass, or the glass from you (possibly both)?

• What is the location of the handrail (inside, on the top)?

• What shape is it (if it is flat does it encourages a cup, phone or ashtray to be left on it – until of course that item is knocked off)?

• Is it bare metal located outside (if so, it may reach skin-burning temperatures in the summer – an aspect that may be lessened if the metal is coated)?

• Is it capped?

The ‘capped’ question was kept to last because it has several factors. Architects often favour balustrades with no features at all – and understandably so – the elegance of the unobstructed view. However, this is not without its problems. Some interlayers, when left exposed, absorb water or crack or delaminate or are just difficult to clean. The exposed edges of adjacent uncapped glass panels are virtually impossible to consistently align acceptably, and even where they are aligned, the upper corners can form a sharp edge.

Over time, chips and shells are common, creating even sharper edges, and are made more likely to occur because of the misalignment and exposure. This obviously presents a potential cutting hazard to a hand. This is exacerbated when the top edge of the glass is not horizontal, such as on a stair.

One corner of the glass will be an acute angle, creating a piercing point, or a chance of catching clothing – potentially throwing the descending person off balance. Capping the glass with a simple, small channel can alleviate most of these issues, and can even enhance the aesthetic – particularly over the long term. It may even create a greater level of comfort, a feeling that there is no railing or balustrade can be quite disconcerting for many people.

It is clear that in spite of centuries of design and installation, there is still too much evidence of incorrect design and poor installation. The information offered above may not cover every event or condition, but knowing to look for the issues will hopefully take us a long way towards an installation that will be durable and practical, and most importantly provide its safety function in every case.