Please mention a few important hardware that goes on the doors and windows?

Mortice or cylinder locks, lever handles or pull handles or knobs, surface mounted or concealed door closer, card readers, eye viewers, electromagnetic door holders, flush bolts, panic bars, floor stops, hinges, and glass hardware patch fittings are some of the hardware commonly used in doors and windows.

Please comment on the need for choosing the right kind of hardware for windows, doors and façades?

Primarily, openings in a building are the easiest locations to break in. Also, controlled openings like windows and doors are dynamic in comparison with other building components. So, it is important that we use the right hardware for our own security and safety. Secondly, the entrance door and its handle will be the first component that gets sighted or used by anyone entering your house, so it should be aesthetically appealing.

List a few factors to consider while specifying architectural hardware for doors and windows?

Door and window hardware are of day-to-day use. Therefore, it is imperative that factors like hardware durability, strength and easiness in use should be kept in mind during the selection process. It is also better to avoid sharp edges. The designer may specify a product by considering the extent of exposure, the function of the building and individual room. It is also advisable to use products with quality standard certifications. Fire-resisting requirements should be specified.

Please brief on the evolution of door and window hardware over the past two decades.

Globalisation has allowed economic and industrial institutions to interact freely without any major border restrictions. This facilitated many international companies to market their products in the Indian market at competitive rates. This influx of products increased the competition, which in turn benefited the customers by providing them with innovative hardware products with an assortment of finishes and mechanisms. The gyration in the field of information technology has brought about access control and access management systems.

Kindly throw some light on the latest technologies and materials for architectural hardware available in the Indian market?

Door and window automation has gained more popularity in India in recent years. Key card using magnetic strip or RFID reader technology is used for the security systems for office, commercial and hospitality buildings.

Also, many of hardware manufacturers have added a variety of shades and finishes to their standard product portfolio. Colour customisation to match the design theme became easy to achieve. Heavy-duty pivots with adjustable points are now available to support large shutters that require minimum effort to operate. Concealed hinges and concealed door closures have provided more design flexibility to the designers. Glass partitions, shutters and patch fittings are immensely used.

Please explain the standards and certifications you look for, to make sure that their products are of superior quality?

BIS / ISI marks are the general quality marks for the products in India. However, the Indian market has a great scope for improvement in ensuring quality marks for many architectural hardware products. Many hardware companies have achieved ISO 9001 certifications for quality management though, which can be looked into. Products with a CE mark represent conformity to EU standards.

Are there enough products available in the market, which would satisfy the needs of architects/developers and builders?

There is no dearth of products in the market for the common uses. Continuous improvement and innovation are inevitable and the Indian market can definitely accommodate more competitive products.

Tell us about customised architectural hardware. What are the advantages and hurdles façade by you regarding customisation?

Customisation of hardware is generally done to satisfy the specific design intent or to take care of a unique function of a building or room. Customisation helps to improve aesthetic performance and also caters to individual customer preferences. Quality, functionality and durability should not be compromised during customisation.

Tell us about the future of the Architecture Hardware industry for façades and fenestrations?

Before the COVID-19 pandemic, 6-7% annual growth was expected in the field of architectural hardware industry in the next five years. The economic slowdown is anticipated to last for one year due to the virus.

More IT and smart phone-based automation is expected in the near future, hence suitable hardware will be required. Also, the contribution of Nanotechnologies like Nanomyte coating and the contribution of Artificial Intelligence (AI) to design and manufacturing may be future revolutions.

Please give us a brief note on your latest project in which façade / fenestration hardware products are used innovatively?

Turner International successfully handed over ‘Talan Towers’, a mixed-use project comprising luxurious hotels and residences in Nur Sultan, Kazakhstan at the end of 2017. The performance of external doors and windows was extremely important to reduce the impact of the stack effect due to pressure differences caused by extreme outdoor temperatures which may even go lower than -350C.

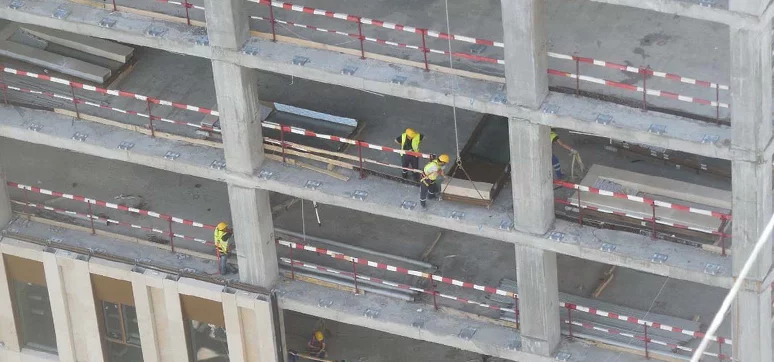

The selection of air and acoustic seal and gaskets was done carefully to minimise the draft. Also, heavy-duty customised pull/push handles were used to open the doors in high air pressure conditions. The above project had a state of- the-art façade, which is a combination of natural limestone, insulated aluminium and triple glazing filled with inert glass. Unitised panels were heavy due to the above combination. Heavy-duty insert channels and brackets were therefore used to connect the façade panels with the concrete structure.