Schmalz, one of the market leaders in vacuum automation and ergonomic handling solutions, has revised its SQC vacuum clamping system for glass machining and made the design perfect for the interfering contours of the original equipment. This makes the use of Bystronic glass grinding machines even simpler. Thanks to the quick-change system that can be operated without tools, setup times are significantly reduced.

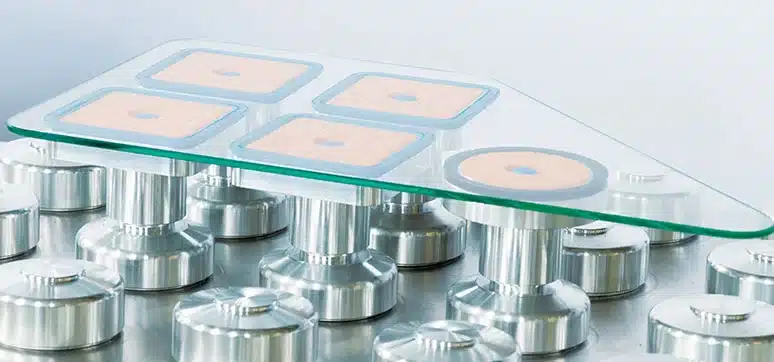

Schmalz has developed the system, especially for CNC machining centres made by Bystronic. This allows grinding of glass work pieces, for example designer and automotive glass on all sides. Thex clamping system consists of the suction cup mount (base), the suction cups and the covers for the unused vacuum connections. The cover protects the connections and mechanical parts of the change system from contamination. When changing work pieces, the users can retrofit the system very quickly.

The base is fixed with a hollow bolt and can remain permanently on the machine table. The suction cups can be easily attached. To remove the suction cups, only one push button must be pressed. The covers are also effortlessly attached and can be locked in a similar way to a bayonet fastener. Additional tools are not required.

The new Schmalz system is also very flexible: Depending on the glass geometry, the user can now choose between square and round suction areas. As a result, the Bystronic machines can be retrofitted on a one-to-one basis with Schmalz suction cups. Due to the slim shaft of the aluminium housing below the suction area, the suction cups can be placed closer to the processing edge. The machining becomes even more precise and low vibration. Combined operation with the original equipment and Schmalz suction cups is also possible.

The cups installed on the machine table suck in and fix panes of different geometries. Smooth machining and peripheral grinding is possible as a result. Users produce very precise and dimensionally stable parts. An abrasion-resistant coating allows the absorption of high lateral forces between the suction cup and the glass part. The work piece always remains securely in position even with strong lateral forces. Glass sheets are handled particularly gently. Incorrect clamping can quickly lead to damage and expensive waste. In order to prevent this, Schmalz makes the interchangeable sealing frames of its system with the material HT1, which leaves very few marks.