As smart building technologies become more prevalent, how do you see façades integrating with these systems to enhance overall building performance?

Smart technologies today are not just prevalent but have become an integral part of our lives. With apps controlling the lights, air-conditioning, entertainment, coffee machines, and whatnot, building fenestrations are not untouched by smart technologies today. From integrated blinds within IGUs, digitally controlled and programmed electro-chromatic glass products, to dynamic shading devices that can change orientation, position, and location, to daring adventures where roofs and façades are designed to function dynamically to control light and visibility, façades have come a long way. All these features being connected to building automation and maintenance systems make it even more relevant today.

Apart from thermal performance, intelligent smoke and ventilation systems involving façade automation, which are triggered in case of emergencies to help mitigate fire risks elevate the building performance above and beyond the safety offered by conventional passive systems. AI-enabled thermal detection camera-controlled fire hoses tackling localized façade fires over façade have also been experimented with, where strategically placed firefighting systems over the building face detect localized façade fires and extinguish them within critical time to avoid further spread.

What innovative materials do you anticipate will play a significant role in the development of future façades?

The choice of materials is endless when it comes to façades. What is exciting today, is that product innovation in materials has moved beyond offering ‘pretty looking’ materials to sensitive choices which helps the designers and developers meet their core principles while delivering the projects.

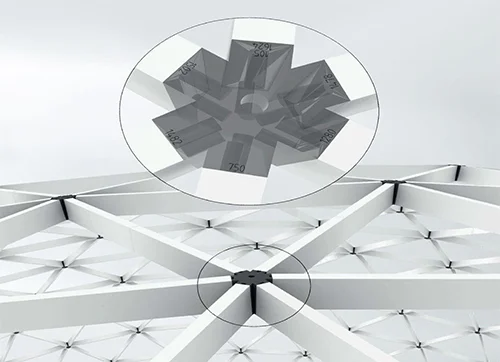

With the sensitivity toward the environment, leading manufacturers are offering recycled glass and aluminium products. With leading glass manufacturers finding ways to increase the cullet and system manufacturers introducing systems using up to 75% recycled aluminium, such as in the case of the Technal CIRCAL series, designers have a choice, to begin with, low embodied carbon for the two major components of contemporary façade systems.

From a thermal performance point of view, the availability of high-performance glazing with low-iron glass and triple silver coatings helps designers meet their performance goals without compromising on aesthetic quality. Advancements in ceramic fritting and digitally printed glass allow designers to control the window-wall ratio without compromising on the glazed area and material pallet. Thoughtful frit patterns over façades based on the sun’s path can help maximize the daylight while keeping the harsh sun away.

Laminated glass and the range of interlayers have started to play an important role in how glazing is looked at. From imparting different qualities such as translucency, colour variations, acoustic performance, structural performance, and safety toward blast-proofing and bulletproofing while maintaining clear visibility, PVB and SGP interlayers are changing the way glass is used in contemporary buildings. Building integrated photo-voltaic panels are also being integrated within the façade.

What are the essential tools used in the creation of future façades?

Façade development has three crucial phases – the vision developed by the Architects, the development of façade solutions with systems that can meet this vision, and the fabrication and installation stage which makes this vision a reality. All these three phases demand different tools and different attention at every stage.

With the future of design heavily relying on parametric and generative design principles, a large set of dedicated software as well as plugins are helping designers envision building skins that optimize environmental performance and push toward a sustainable built environment. With BIM being the industry standard and the way forward, the design information is loaded in at a nascent stage.

Façade models are then further detailed to capture the system nuances, material characteristics, and performance parameters, which can be analyzed in the larger building model to simulate the results, allowing further tuning to achieve established performance goals. Calculations for embodied carbon, impact on MEP, costing and value engineering, material optimization, and quantification can all be done within the BIM environment.

Beyond this point, the fabrication and installation discipline, popularly called the contracting world has a different set of tools that are gaining higher ground on innovation as compared to the digital counterpart. Fabricators and system manufacturers are investing in multi-axis CNC machines which can be programmed to process façade components from a simple extruded profile to a fully fabricated set of parts ready to assemble with strictest of the tolerances and high-quality control. Metal 3D printing is gaining popularity within the industry with innovative systems such as Schueco’s ‘Grid2Shell’ and Technal’s ‘Tental Parametric Façades.

Can you provide insights into the recent advancements in façade and cladding technologies, including materials and construction methods?

With an everchanging building landscape and a constant stream of innovative and unique design solutions by Architects, façade and cladding materials as well as the methods of putting them together are in constant development. The industry is majorly moving toward pre-fabricated site-installed façade systems for the correct reasons, and integrating, transporting, hoisting, installing, and testing such systems is increasingly challenging. Pre-fabrication and unitization of façade systems reduce the work on site and help in maintaining the quality of façade systems at the fabrication facility. It also helps reduce the time required, as fabrication happens parallel to the construction at the site, and reduces the site-associated risks.

Given the increasing focus on sustainability, future façades shall be seeing rapid integration of renewable energy technologies, such as photovoltaic panels or solar-integrated cladding. While roofs have been engaged before for the installation of photovoltaic panels, the limited area available which is shared with other building services considerably reduces the available surface area. With the advent of High-Transparency Window-Integrated PV panels, Façades can generate energy, helping decarbonize the built environment.

Could you share your favorite façade material and explain the reasons behind your preference?

I would love to answer that as an Architect, but as someone helping fellow designers to take their design intent to a built product, I am unfortunately not allowed to be biased for or against materials and systems and tend to choose a material or system that can achieve the best results for the proposed design intent. The projects I find interesting are the ones where the qualities and strengths of a certain material or set of materials are capitalized to achieve a thoughtful design intent.

What features would you like to see incorporated into future façades to enhance their functionality and aesthetics?

Façade industry is dynamic and we’re all learning new things every day. At an early design stage, the designers need to understand the available materials, their strengths, and their limitations. Considering available stock sizes of materials to optimize their usage at early design stages can help achieve ‘zero waste’ façades.

Performative testing and the use of certified materials in façade are equally important to ensure anticipated results. With the constant flow of attractive materials entering the market and the excitement of designers to build something unique, it happens far too often that materials that are not tested for their performance make it to building façades. Their reaction to fire, weathering, and integrity when installed within a defined façade system remain questionable and their use might unfortunately be a calling for undue events risking life and safety. Performative mock-up tests also enable designers to empirically establish the performance of façade systems and fix any shortcomings before application over the actual project.

When it comes to functionality, it is important to note that façades need timely cleaning and maintenance. It happens far too often, unfortunately, that the façade access and maintenance systems for even large projects are completely ignored and the developers just end up delivering a pretty building. Proportionate investment in appropriate BMU systems is pivotal to a functional and durable façade, which looks good and functions well throughout the building life-cycle and not just the first few months.

How does automation play a role in façades and fenestration, and what are the associated benefits of incorporating automation in building exteriors?

Today automation by far is largely limited to home interiors, with a lot of system manufacturers now offering motorized door and window systems. As dynamic façades along with façade lighting and modern glazing materials start gaining traction, the skin systems will be much beyond a static set of materials. Buildings will be programmed to be more ‘climate reactive’ than ‘climate-sensitive’. With the integration of automation and artificial intelligence in every aspect of our lives, façades will soon enjoy the benefits of the digital revolution with the integration of dynamic components.

What are the key Characters of a High-performance Façade?

The performance of façades is primarily associated with their thermal performance – may it be avoiding radiant heat or trapping the embodied heat within a building depending on the location of the project. While thermal performance is the key driver for high- performance façades, other aspects such as durability, fire performance, safety, air tightness, resistance against water permeability, the integrity of materials, quality of finishes, and compliance with international codes and standards – all contribute toward making a High- Performance Façade. Demands from façade are becoming more complex as standards keep on updating. Nations and cities are gearing up to implement stringent codes and standards addressing the performative aspects of façade systems. Façade systems employed on the projects should meet and exceed the international standards as we progress.

In the context of climate change, how can façades be designed to withstand extreme weather conditions while maintaining their aesthetic appeal?

We have all seen faded colours of once bright-coloured shopfronts around town, which were novel a decade or two ago, deformed cladding panels, dislocated louvers, and stained glass canopies with rust streaks from spider fittings. Although the ageing of a building is not completely avoidable, modern materials, if chosen wisely and installed correctly, can last longer in worsening weather conditions.

It is important to choose the correct coating for exposed aluminium cladding and extrusions meeting international standards. Choice of the right hardware, fasteners, gaskets, and silicone compatible with materials in contact, bi-metallic separation, proportion of panels, and making sure the systems are designed to withstand the anticipated wind loads are a few factors that are vital while designing façade systems.

Performance glazing plays a vital role in addressing the extreme weather and innovation in high-performance glazing shall lead the path for how the industry reacts to climate change.

As urban spaces become more interconnected, how might façades contribute to creating a sense of community and connectivity within and between buildings?

From the digital screens of Times Square, the celebratory face of Burj Khalifa, exterior green walls of Singapore, to sculpted honey-comb curved columns and canopies of Mumbai Airport, façades all over the world can define a sense of place and affect everything that happens around them.

While the experiential quality of architecture can be overwhelming through its spatial characteristics, the first relation a user makes with a building is from the exterior. Façades make the first impression on the user. With designers paying more importance to integrating interior and exterior by blurring the boundaries, building skins are becoming more permeable in nature. Designers are expecting performance glass products with higher light transmission while retaining the thermal performance. As designers continue to blur these boundaries, façades need to be extremely flexible while providing the necessary protection and performance.

How do you envision the future of façade design, considering the evolving technologies and materials in the field?

With conventional architecture where the structure, fenestrations, and finishes were indistinguishable and designed as a larger system forming the external building wall, façade design as a specialized discipline barely existed. Façade meant the ‘exterior road facing side of a building’.

With evolving building technology, the advent of new materials, and the growing general scale and pace of construction, façade design has found a new meaning. Today, façade systems serve as the primary and many times the only barrier between the inside and outside, hence making it necessary for them to be robust from structural, environmental as well as safety perspectives. Façades need to perform all the functions of a conventional external wall, along with imparting a unique and contemporary appearance to the structure.

We see the construction industry move toward a modular approach as we progress, and the integrity, performance, and novelty of façade systems are becoming more critical than ever. It therefore requires expertise not just limited to Architecture or Façade systems in isolation, but to a more holistic outlook, where façade engineering meets façade design leading to better performing, durable, safer, and ‘Future-ready Architecture’ reminiscing from where Mies Van Der Rohe sparked the early dreams of glazed façades with his early curtain wall experiments in Chicago, preaching that ‘God is in the details.’