Architectural hardware plays an essential role in every type of construction, whether it is for residential, commercial, or industrial. The story covers the growth of the architectural hardware industry in India and the various factors influencing the same, the latest developments in the industry, challenges faced by brands, and tests and test methods for deciding the quality of the hardware. We spoke to many industry experts from various brands regarding these topics. Presenting their views, solutions and suggestions which will help the AEC industry members to make informed decisions.

Market Growth and Demand for Architectural Hardware

The growth of architectural hardware is synonymous with the growth of the window, door and façade industry. Architectural hardware has evolved a long way since the year 1998 when the aluminium façade market started to make a mark in the Indian fenestration industry. From there, being no symmetry in the profile design to having a more defined requirement in terms of solutions, application and testing, the products have come a long way, notes Deepak Chugh, Managing Director, LGF Sysmac India Pvt Ltd.

Increasing residential construction such as townhouses, bungalows, and row houses are demanding architectural hardware, also driving the growth of the architectural hardware market, says Atin Thacker, Marketing Director, Geeta Aluminium Company Pvt. Ltd.

According to Anil Sinha, General Manager – Sales, McCoy 8M, the hardware industry is poised for tremendous growth since more and more consumers are looking for solutions that are off the beaten track and not just run-of-the-mill ordinary doors and windows. With the introduction of doors and windows with special hardware like tilt & turn windows, slide & fold doors, lift & slide windows, vertical windows, etc., in the market, the discerning consumer is more informed and, therefore, more demanding.

If you see the last two years, there were a lot of ups and downs in every segment because of the fluctuation in raw material prices, notes Raman Dhiman, Director, Glorious Products India Pvt Ltd. (Insta Hardware). But after the pandemic, the market started picking up.

The Indian fenestration market is divided into uPVC, aluminium and wood. We have seen substantial growth in two categories – mainly in aluminium and then uPVC. Besides the project market, the retail market has also grown in a couple of years. This means a lot of opportunities have been created for system doors and windows in the Indian market. New products have been launched in the market mainly for slim profiles and new systems, adds Dhiman.

Hemant Kathuria, Director, Taiton Trading Pvt Ltd also mentions that for the splendid growth witnessed in the architectural hardware industry, many credits go to the architects and interior designers who plan the hardware in the designs, and the contractors for perfect execution. With the advancements in technology and robust coating processes, the client now has multiple options for hardware to choose from.

An active effort by architects and consultants focusing on sustainable designs, the demand for automation of doors and windows is on the rise, notes Tony J Perayil, Dy. General Manager, Kinlong Hardware India Pvt Ltd.

Most international players are present in India through their direct presence or distributorship. Indian manufacturers are also building their brands and introducing new products. In my opinion, says Abhishek P Kale, Area Manager India, Sobinco NV, real growth of the hardware industry will happen when windows, doors and façades are looked at as essential elements in the building, which have aesthetical and functional requirements. More disposable income in the hands of people, more demand for better products, he adds.

Though it is predicted that the hardware industry will see tremendous growth, its market is still at an initial stage of growth in India. After the ‘Make in India’ initiative by GOI, several manufacturing companies have started their production units in India from overseas, as well as locally. “Being a developing country, the required technology for producing a quality product is still a challenge for us which ultimately increases the dependency on established companies from overseas.

This sector still hasn’t contributed too much to the economy of India. Certain policies by the Government towards ease of doing business is now providing sufficient limelight for future investment in the hardware sector”, points out Prashant Gautam, Zonal Manager, Kinlong Hardware India Pvt. Ltd.

New Developments

When we come to think about the new developments in the fenestration and façades industry, it should go much beyond aesthetics. Thermal insulation, sound insulation and resistance, energy efficiency, safety, and less maintenance are the major aspects to consider. Timber and other wood products are almost replaced by newly engineered products either in uPVC or aluminium.

“After certain years, aluminium may take over the market with new designs, colours, light and air utilisation, and with its ability to keep unwanted sound outside”, predicts Gautam.

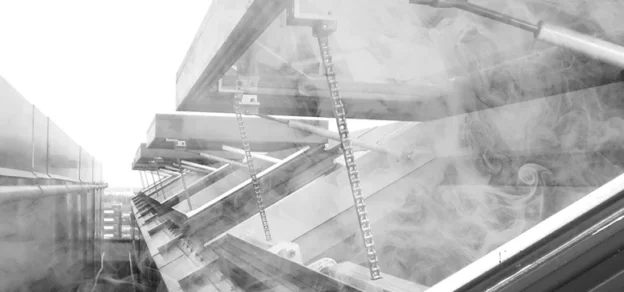

Such designs of new developments for doors and windows give a wide range of options to choose from with specific styles for specific areas of the houses. Similarly, façades have changed a lot in the past decades from normal complete concrete structures to glass with steel structures, whether by using MS, glass fins, tension rods, or tension cable.

As windows and doors get slimmer and need more performance in terms of weight and dimensions besides the warranty on the product line, hardware has also seen changes in offerings. With automation and smoke ventilation coming into the picture; the architectural hardware industry has braced itself with products on the line already, notes Chugh. Use of new minimalist designs and attractive finishes are a clear preference over large bulky and industrial-looking hardware, says Thacker. For security and locking systems, the trend is moving more towards digital and advanced integrated systems.

There is a lot of development taking place in the surface finishes of the hardware, especially patch fittings, shower fittings, railings and other glass Hardware, observes Kathuria. Lately, the downward trend of the use of frameless glass is seen as slim aluminium sections are being introduced in the market. Awareness and possibilities in digital transparent façades are being probed particularly in the retail sector, notes Perayil.

The perception has changed glass façades from being only for aesthetic purposes to revenue-generating alternatives. Products like PDLC glass, dynamic and kinetic façades, cast-in channels, etc., are a few developments in the façade sector. Looking at fenestration, energy-efficient windows, aesthetically pleasing threshold design, and 100% transparency configurations are the latest (slide fold, slide turn, corner slide), points out Perayil.

The trend towards aesthetics is also accepted by our Indian market as ‘Dynamic façades’ and ‘Parametric façades’. Change of perception in the usage of smart/intelligent access control systems is a requisite rather than a luxury. The demand for better aesthetical solutions plus automation is gaining traction in fenestrations and façades.

Growth of Organised Architectural Hardware Market & Customer Demand

Most of the experts we spoke with agree that the organised architectural hardware market is growing on the back of customer demand. As the industry is having a demand for new systems, the architectural hardware manufacturer has to give solutions for that. This is one reason for the organised architectural hardware market’s growth, says Dhiman.

According to Gautam, though the Indian architectural hardware market is growing in every aspect of the construction industry, still it is not completely organised in a good manner. The understanding of customer demand is being fulfilled, but the majority of product dependency is still on overseas brands due to less work in innovation, research and development. To keep up with the demand from the new generation, the resources are still less.

Certain regions in India have also started working assertively on this part. As can be seen in Gujarat, the evolution of hardware production is providing a wide range of options to the customer. Certain other states are also focusing more on industrialisation which can bring revolution in the hardware industry. According to Chugh, the products always existed in the overseas markets; just that India has now started to demand this. This growth is a mixed attribute coming from customer demand and knowledge sharing done by the manufacturers.

Kale too observes the significant changes in customer demand. There is a very thin line between hardware and accessories. Fabricators and systems houses are working in a more organised fashion. The supply chain issues when orders are executed at the last moment is a major hurdle. convincing the customers to finalise hardware at the time of finalisation of their aluminium order will avoid final minute hassle for delivery and execution, says Kale.

With the development in all sectors (government, private, hospitality, healthcare, etc.), strong demand for architectural hardware has been created in the market, which allowed a lot of regional players to grow, says Kathuria. This led to the introduction of many cheap, sub-standard, inferior-quality products in the market too. In the last 3-5 years, customers have become more quality-conscious and demand strong, durable and robust products. They spend a lot of time evaluating and comparing the quality and pricing of different brands before finalising the order. It has also been noticed that the product specifications are getting stricter in the government tenders too. Everything sums up the growth of the organised architectural hardware market.

Performance of the Real Estate Sectors & Growth of the Hardware Industry

The growth of the architectural hardware industry can be understood by extrapolating the behaviour and growth of the underlying macroscopic environment in which this industry is inherent. In Q1 2022, new launches increased by 36% q-o-q. This marks the highest quarterly launches recorded since Q1 2014. Sales volume during Q1 2022 grew by 11% q-o-q; it scaled a new peak for the second straight quarter (since Q2 2013) as Bengaluru clocked the highest-ever quarterly sales and MMR saw its sales stand at an 11-year high in the quarter. The expected time to liquidate stock decreased notably from 4.7 years in Q4 2021 to 4.2 years in Q1 2022, a clear indication of sales growth outpacing the growth in unsold inventory. Residential prices rose by an average of 2-4% q-o-q in Q1 2022 in select micro-markets across all the top seven cities. From the above data, it can be extrapolated that; the Q1 sales grew by 148% over pre-Covid levels and new launches in the cities of Bengaluru, Delhi and Mumbai tend to provide a positive outlook on this financial year and the upcoming.

To conclude, firstly, a major part of the fenestration industry and therefore the architectural hardware industry keenly rely on the cash flow from the customers for taking forward their R&D and expansion plans, this, in turn, is a crucial factor in propelling the industry forward. Secondarily, there is mounting pressure from all stakeholders in the real estate industry to contribute to lower carbon emissions and more resilient buildings and cities. Regulatory initiatives and new construction techniques and materials will be important factors in ensuring new buildings meet higher standards. But with building operations contributing 28% of global greenhouse gas emissions, managing energy performance in existing buildings will be essential in meeting net-zero carbon commitments from investors, tenants, landlords and governments. Passive-energy-saving methods such as double-glazed façades and fenestration play a key role in reducing energy consumption.

(Tony J Perayil, Dy. General Manager, Kinlong Hardware India Pvt Ltd)

Challenges & Roadblocks in the Architectural Hardware Industry

Every industry has its own challenges. According to Dhiman, in the architectural hardware industry, the main challenge is the specification and the selection of hardware. The customer’s preference is always to compromise the quality over the price and that leads to the wrong selection of the hardware, like the purchase of non-standardised products. In the Indian market, we first design the system and then look for hardware, which is wrong. Agreeing with Dhiman, Sinha comments that the demand for cheap, non-standard and local hardware is the biggest challenge for the organised architectural hardware industry. “Since most of these items were being imported from China, Turkey, etc., there was a lack of quality and supply consistency. Now, as more and more people are gearing up to develop the items indigenously, the problem is expected to alleviate”, hopes Sinha.

According to Gautam, the major challenges for the industry are the lack of knowledge, an unorganised sector, improper planning and most importantly choosing prices over quality and safety. The market related to designing and architecture is still following traditional methods of hardware selection, whereas the hardware industry has already risen to a much higher level. But the platforms to demonstrate or to give education on these new developments are very less.

He stresses the need to educate the customers on the latest technologies, new products, their usage, and the advantages of using these products. The GOI has now started to make some policies towards standardisation in terms of safety related to hardware usage and execution of systems, which also needs to be regulated to not let anyone compromise safety. The inter-competitiveness is also another challenge where certain organisations reduce the prices for only business purposes, evading safety, which can be solved once all organisations come together to standardise the safety protocols and quality of the hardware, notes Gautam.

The main challenge for hardware is the priority given to it in the procurement list and budget allocation, notes Kale. There is a need for speeding up deliveries. Another challenge is the tolerances between hardware and section. Very little focus has been given to the same and problems come to notice when the project is halfway in execution. With the introduction of new concepts in hardware, the ground force also needs training and new tools. Using the same set of tools and approaches will not yield the desired results. Another major roadblock in the hardware industry is that it is still considered a low-scale/low-volume industry. There is very little investment in basic infra/machinery.

Mostly traders source and sell with some margins at very low prices. There are no standards/specific specifications or tests which are defined for India, adds Kale. “We honestly miss a great manufacturing facility in India that can provide home-grown solutions to this market. Considering that designing new aluminium profiles is not cost-prohibitive, their abundance and variance of them is a major headache for the hardware industry.

Besides that; the need for customisation of products – be it the product itself or the coating is another roadblock, which will only get eliminated once we have a local manufacturer in place,” observes Chugh. Negligible work has been done on the use of Hardware with respect to the standards, specifications and guidelines. The absence of a hardware manufacturers/suppliers association at the national level makes the situation confusing,” avers Kathuria.

Perayil lists the following as the major challenges:

A. Standardisation: The Indian architectural industry is highly dependent on other national standards for its workings, mainly the EU codes. Only the top façades and fenestration fabricators strictly follow the standards and testing criteria. These standards are not considered or regarded by the builders and developers during their design stage, therefore it is a partially compatible system.

B. Planning and Procurement: Effective procurement processes are critical for financial efficiency. It helps pay the right price and ensures timely delivery while ensuring you choose the best partners to work with. In the course of a project, it is very important to make the procurement choices at the right time, as the locally manufactured market for architectural hardware is considerably close to the material that is imported. Availability and the fluctuation in the price of raw materials have been the biggest challenge in the architectural hardware Industry. Price revisions in hardware are often met with strong resistance.

Standardisation of Window and Door Systems: A Major Challenge for the Industry

The market and the hardware industry are facing difficulty due to the absence of standardisation. Due to the lack of standardisation in this sector, the actual design part compromises the actual execution part. It makes the complete system get compromised at different levels, says Gautam. “Hardware is the major entity that helps in making the system operational, providing safety and enhancing appearance as well. We can rectify this challenge, but the inappropriate demand and competition among the different companies make it tough to follow a certain path. Each person who is related to such a specific purpose needs to be qualified and trained enough to follow the basics and bottom line for it to be decided”, adds Gautam.

Chugh too agrees that standardisation is essential, more so in aluminium. The uPVC window and door systems are more blessed in that respect. The way forward is for the industry to come on a common platform and define what is acceptable. Perayil advises to opt for aluminium profiles that are designed as per the EN standards, to be readily compatible with all the major hardware brands. Whether it be fabricators that extrude their own profiles/designs, or fabricators that procure readily available profiles, both can incorporate or opt for the profiles designed as per the EN Standards, he explains further.

Educating the concerned shareholders – architects, consultants and builders -at the design stage to follow a planning and procurement schedule is essential. It is the responsibility of hardware manufacturers to work in synergy with profile manufacturers to make standardisation in the market for all the new trends adopted or the particular application/function. Designing an efficient, scalable, secure and cost-friendly system is the main key point in this industry. The window and door industry is dynamic.

“Being associated with architectural elements, we cannot remove creativity from it. There is only one way to control it is by introducing India-specific standards for windows, doors and façades”, opines Kale. It is the need of the hour to standardise the door window systems and hardware similar to what was done in the field of glass a few years back.

Although organised and structured companies have specifications manager who works closely with architects and interior designers to standardise and specify the appropriate hardware in specific projects, that takes a lot of time, energy and effort and can’t cover all projects. Architects, interior designers and the hardware manufacturer fraternity need to sit together and form an association to draft the guidelines on the use of hardware in buildings, recommends Kathuria.

Tests and Test Methods for Deciding the Quality of Architectural Hardware

Several tests have been done apart from normal dimensional analysis during production. Material inspection is done by Spectro analysis, and quality inspection by the quality assurance department in a majority of companies, visually, to avoid any burr, scratch, or other surface faults of the product. Apart from these, there are many tests done on the product to analyse the performance of the material – like opening and closing tests of the product as it shows the resistance of the product after repeated opening and closing in the actual scenario.

The above process also helps to assess the number of cycles that can be achieved by a product to determine the life of a product and how long it can be used. Torsional Testing or an anti-twisting test is also conducted on the products to determine the response of the product under the stress of repeated twisting motion. Anti-corrosion test or passivation testing evaluates the surface of corrosion-resistant steel parts by looking at surface passivity.

Upon testing, material that has been properly passivated will be virtually free of rust and that helps in determining whether there is any need for extra coating on the surface of the product. Furthermore, a Salt Spray test is also conducted to check the corrosive properties and life of the product against a controlled corrosive environment. Other tests like fireproof, bulletproof, and blastproof are also conducted on the usage and application of product type.

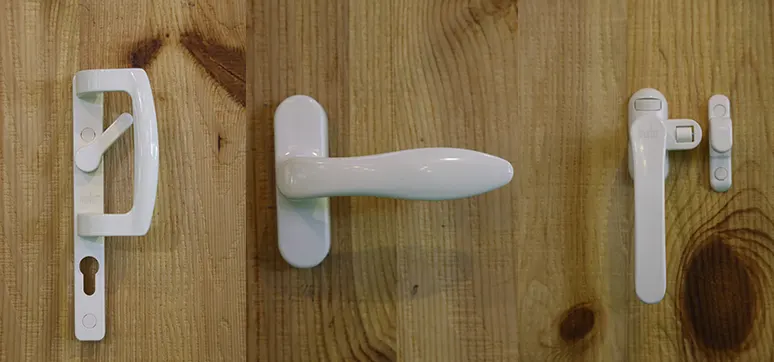

Kale adds that most of the products follow the best of European standards like EN-13126, EN-179, EN-1125, EN1303, EN-1935 and many more, and will have an in-house test centre where one can check the hardware in a real-life scenario. “We check corrosion class after the cyclic test (wear & tear) to check actual real-life scenarios. Sobinco test lab is equipped to check all kinds of performance and safety-related tests,” he adds. According to Thacker, the hardware quality should be tested for durability and strength performance, especially for the operation of movable sashes of windows and door height windows.

The most important aspect is to check for any water penetration through the window/door. Security is also one of the most concerning issues, and the design, structure and quality of window and door hardware are very important, particularly in burglar-resistant window and door systems. Performance testing can include various strength, physical endurance, corrosion and operational tests for door hinges, locks, closers and panic exit hardware. It can help ensure that the hardware performs as intended over the lifetime of the product.

Various Quality Tests Performed to Assess Different Aspects of Hardware:

• Salt Spray Test: Resistance to corrosion is tested by an accelerated test to produce moisture corrosion called the Salt Spray Test where the component is put in a tank and sprayed with 5% Neutral Salt Spray solution for up to 500 hours or sometimes even more, and periodically (after 10 hours, usually) to check for the appearance of Red or first White, then Red Rust (for passivation coated components). If the component comes out clean, then it is said to have cleared the 500-hour test and is certified as Grade 5 corrosion-resistant.

• Cycles of Operation Test: checks as to how many times the component can work in the system while in service. Normally, components like handles, rollers, etc. are tested for 25,000 cycles of operation.

• Paint Coating Thickness: is checked for overall paint quality on painted parts like handles. The method of testing involves using a Dry Film Thickness Tester or sometimes a Destructive Test is also done where the sample is broken and the section examined under an Electron Microscope for paint quality consistency.

• Material Composition Test: This is to ascertain the raw material & material grade of the product. It is done with a Spectrophotometer, to check for the presence/absence and percentage quantity of alloying elements essential for the properties of the component.

• Fire Rating Test: This is a major test required for the hardware going to be used on fire doors or commercial places.

• Life Cycle Test: This is another test for floor springs, door closers, etc.

• Tension, Compression and bend Test: for the glass load-bearing hardware such as spiders and railings.

The main testing methods to determine the two broadly classified parameters, ie. mechanical and chemical properties can be summarised by the European testing standard EN 13126, The standard has 19 subdivisions that cover all different aspects of testing hardware.

- Lifecycle testing: Class A, B, C and D testing cycles of 15000, 20000, 25000 and 30000 for windows and Cycles of 25000, 30000, and 35000 for doors respectively for the classes.

- Operating forces – Load Capacity; Salt spray Testing for 48- 480 hrs.

Some of the specific tests done are:

- Preliminary loading

- Open and close the window

- Air Infiltration Test ASTM E283

- Static Water Penetration Test ASTM E331

- Dynamic Water Penetration Test AAMA 501-1

- Structural Performance Test ASTM E330

- Seismic Racking Test AAMA 501.4

- Structural Proof Load Test ASTM E330

Conclusion:

Windows & doors are one of the most important elements in a building. Investments in quality windows and doors yield rich dividends. The right choice of hardware is very critical to distinguish a good window system from an ordinary one. Quality hardware gives the finishing touch to windows and doors for a better look and more effectiveness. Choosing the right hardware is about ensuring that all components meet stringent standards and that they are working together effortlessly. Hardware constitutes a meagre 1-3 per cent of the building cost.

However, over some time, maximum issues arise due to malfunctioning hardware, which can result in accidents and revenue loss. When choosing hardware, function, durability, design and quality should precede cost. The selection process would be easier if the products were tested and certified by recognised organisations. Along with using the right products, it is also very critical to ensure that they are installed properly. The future of the hardware industry is bright and the focus needs to be on innovation and adaptation to the requirements of the customer as well as on sustainability and quality.