Aluminium doors, windows and curtain walls are considered to be the technological and architectural elements with designed functions to interact between two inside and outside environments and are supposed to guarantee general comfort within the home. The main functions between others are mechanical properties, air, water and wind resistance, thermal insulation, acoustic insulation, light and shade, ventilation and safety.

Current Trends In Aluminium Windows, Doors & Curtain Walls In Context To The Acoustic And Thermal Performance

Nowadays, an important element in the design of low energy buildings is the use of high-performance windows coupled with passive solar design strategies. As energy efficiency becomes more important, north Indian designers sometimes look to Europe for energy-efficient standards and technologies, such as the passive house approach.

However, comparing European and Indian windows is complicated by the significant differences between European and Indian energy performance rating standards. The different evaluation methods and boundary conditions also affect product design, as European windows are optimized to achieve the lowest U-values under their respective rating systems, while India is still establishing a foothold in these technologies and implementation in the systems.

The Most Preferred Solution In Windows In Context To Environment

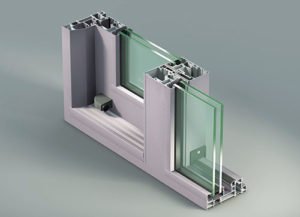

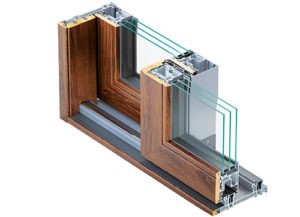

Windows, doors and curtain walls are available in wood, steel, PVC, etc., but those made with aluminium have all the advantages of the unique characteristics of such metal alloy. Aluminium is however also an excellent thermal conductor, and allows temperature migration from outside to inside and vice-versa, acting as a “thermal bridge”. Such a disadvantage of aluminium can be neutralized by using thermal break systems.

Thermally Broken Aluminium Windows & Doors

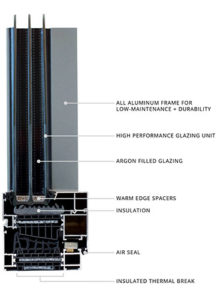

Thermal break, an equally important component in any window and door system, refers to the reinforced polyamide bar between the inside and outside aluminium profiles, creating an insulated barrier within the window frame. In simple words, it acts as a circuit breaker – cutting off the inside with the outside. The frame can greatly affect the actual energy efficiency of any window and door, including that of double glazed systems.

Plus, efficient wall and ceiling insulation will make an even bigger difference to the overall insulation of your home, office or building.

Standard aluminium is a good conductor of heat and cold, which means you can lose or gain a great deal of heat through the frame of the window/door. This can ultimately undermine the performance of double glazed windows. A thermal break needs to be added to the frame.

Thermal break technology features a reinforced polyamide bar between the inside and outside aluminium profiles, creating an insulated barrier within the window frame. This will conduct heat, cold and noise a thousand times slower than standard aluminium.

Performance Advantages Of Thermal Break Systems In Terms Of Acoustics

By installing thermally broken double glazed windows and doors, you will be able to stop noise by up to 42db and keep your home cooler during the summers and warm during the winters. India is a diverse country in terms of geographies, having extreme heat in the west to extreme cold in the north – thermal break works in both these cases.

Sections can be anodized or powder coated with a durable surface coating that can withstand the harsh Indian climate, including UV mage and salt corrosion.

Techniques For Sound Reduction

Silence is golden. Constant outside noise, whether from the vehicle or air traffic, dogs, wildlife, machinery, or loud neighbors, can present a serious intrusion in your home life.

Double glazing is the most common noise reducing system of insulation or soundproofing. Typically called an IGU (Insulating Glass Unit), it comprises two panes of glass, an air gap in the middle, and a specialized frame. The frame, extra glass and air pocket work together as a noise filter to create soundproof insulation between the inside and outside of the window or door.

Standard windows with an ordinary frame and one pane of glass account for a huge amount of noise transmission. With double glazed systems, the window glass, air gap and frames act as a noise reducer. This makes sure that the annoyance of street noise, neighbor noise, traffic noise and even barking dogs can be filtered out.

Using specialized thermally broken aluminium/brass/steel frames, a high acoustic performance can be achieved. Thermally broken aluminium contains a soundproof material that is placed between the inside and outside of the frame and the sash. This creates an insulating buffer against the outside world. Thermally broken aluminium conducts heat/cold/noise a thousand times slower than standard aluminium.

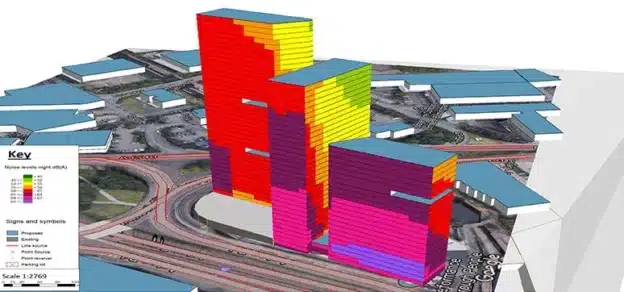

The Weighted Sound Reduction Index (Rw) measures the reduction of sound decibels transferred through a single building element i.e. walls or windows. The higher the RW rating, the better the sound insulation. The Sound Transmission Class (STC) reflects the amount of noise that is reduced when sound passes through a window. Both are the measurements that are used to measure the level of sound insulation in houses, buildings and apartments.

Is it possible to have a thermal break in any other metal? Yes, indeed it is possible to have a thermal break in other precious metals such as brass, corten steel, stainless steel and galvanized steel. Although the market for them is very small as aluminium is the most preferred metal with the architects for performance and value.

The Market For Thermal Break Systems In India

Thermally broken window frames have been available for a number of years, but for some reason their uptake has not been as rapid as might be expected from the promotion given to them. In the exterior wall of a house, the most thermally inefficient portion is the windows. We tolerate this disadvantage because the inhabitants like to be able to look out, and also the glass allows radiant solar energy to enter the building so as to give a positive thermal gain.

A double-glazed aluminium framed window has an R-value (insulation) which is only about a tenth of that of the adjacent insulation wall of standard construction. Now, the customers are getting aware of thermal break systems, whether through social media or personal references, definitely, the trend is going upwards.

On the architect’s demand side, the demand for (both: acoustic and thermal) high-performance fenestration products continue to increase for noisy metropolises, and utilization of more efficient material will need to be augmented by the introduction of more innovative and efficient designs. Manufacturers are rushing with new products to help builders, and designers to achieve higher levels of comfort for both residential and commercial constructions in the best way possible.

Customers are only getting more aware of the energy consumption and how to minimize the carbon footprint. Many European countries offer a tax rebate when citizens are using certified high-performance systems for fenestration. The governments are aware that energy saved using these systems is substantial and helps in minimizing the carbon footprint and savings for both, as the customer gets reduced energy bills while for the government, the environmental impact is minimized.

Criteria For Selecting The Right Values For Certified Windows

Firstly, it is important to be aware that NFRC, ISO, and passive house U-values cannot be compared as they are based on different calculation procedures. For example, when comparing a product from Europe and a product from North America, designers should ask for and compare values determined under the same standards.

Going forward, it may be useful for the industry to add subscripts for the NFRC and ISO U-values to distinguish European from the North American U-values (e.g. UNFRC, UISO). Those comparing certified passive house window U-values should be aware that results are climate-specific, and have been determined according to different boundary conditions for the different climates. For instance, the cold-temperate climate, passive house recognizes both U-values determined at 0ºC and 5ºC.