A Candid interview with Naresh V Narasimhan, Architect & Managing Partner, Venkataramanan Associates (VA) talks about his practice and its growth, his ongoing projects and a few of his milestone achievements, selecting apt materials for façades, sustainable and energy-efficient elements of façade design, and much more.

Please tell us about your practice and its growth over the years.

Over the five decades since its founding, Venkataramanan Associates (VA) has built a formidable and growing knowledge base in architectural design and design-build processes. P.K. Venkataramanan set a strong foundation for much of the work that the firm is now so well known for, such as the Raman Research Institute (RRI), multiple buildings at the Indian Institute of Science (IISc), as well as several office buildings and housing projects.

Since then, the firm has diversified into multiple sectors and expanded its presence in India and abroad. VA is now responsible for a wide range of work spanning Research and Development facilities, specialised manufacturing, IT business parks, public and institutional buildings, corporate offices and Real-estate developments.

All of VA’s work is based on a deep understanding of the transformative impact of architecture. Our ability to design high-quality buildings is fuelled by an earnest appreciation of visionary ideas. Innovation has always been fundamental to our practice – exploring better methods of space-making and the usage of the latest materials and technologies.

Our architects carry out in-depth analyses of site, feasibility studies, sustainability studies, and we use several new-age technologies such as augmented and virtual reality to create a spatial experience.

This sets apart VA’s approach to design. Architects, especially now, have a responsibility to design buildings that respond to the emerging global concerns regarding the use of energy and resources.

Tell us about a few of your ongoing projects.

We have a wide range of ongoing projects, each catering to a different scale, complexity, expertise, and sector. Some of the notable ones include – the HPCL Campus, Presidency School, IISc IDR Campus, Prestige Falcon City, Welspun Logistics Park, Volkswagen manufacturing facility, etc.

There are many glazing materials available in the market. How do you choose the apt one for your project? What are the criteria?

Glazed façades are known to be one of the most glamorous components of buildings today. Nowadays, improvements in glazing technology have made it possible to render different types of glazing for any specific surface, but in doing so the project might end up being more complicated than necessary.

Therefore, it is essential to assess the realistic needs of the façade – its climatic suitability, aesthetic appeal, load on the built form and energy efficiency.

How would the façade design and other elements of the façade help the building to be energy efficient, at the same time provide a better interior environment?

The new trend in façade design is leaning towards reviving vernacular materials in modern form while harmoniously blending them with composite materials. Architects now understand the significance of sourcing relevant materials found within a certain radius to be vernacular and hence truly sustainable. This outlook coupled with sustainable construction processes weaves in sustainability at the early onset of a project.

One of VA’s award-winning projects, Lupin R&D Centre uses materials that are locally available, and eco-friendly, and ensures that nature is preserved and unharmed. High energy-efficient glass is used to maximise daylight and minimise heat gain. In addition to this, the façade design maximises on the locally available natural stone with low embodied energy and recycled high-pressure laminate as cladding material.

What are your views on future façades technologies and materials?

In the last century, all the major experiments in building envelopes were focused on aesthetics and environmental protection. Future evolution will shift from façades being just an envelope to them participating in structural functions as well.

Lupin R&D Centre Pune, India

Key attributes of the façade of Lupin R&D Centre

Thermal Comfort: Being a laboratory building, the interiors require high lux levels (minimum 500 lux), without compromising on the views to the outside. To comply with the requirements, the façade utilises large glass surfaces to harvest maximum daylight and provide unhindered views of the exterior.

High-performance glass [PPG Solarban (6 mm Clear REF + 12 Air Gap + 6 mm Clear)] was selected for the façade, which provided a high VLT of 70 and a low u value of 1.5 W/sqm-k. In addition, heavy shading with deep pergolas and SS mesh second skin are added. Vertical fin elements Vertical fin elements clad in HPL Trespa further cut off incident sun rays clad in HPL Trespa further cut off incident sun rays.

Acoustics: To ensure recommended indoor sound levels (35db as desired by the client), the design combines 24mm IGU and a well-designed aluminium profile with an EPDM gasket sealer.

Wind Resistance: The entire façade system is designed for a wind load of 150 kpa.

Fire Safety: Fire stop joint spray is used to prevent the spreading of fire. Also, the material used meets LEED requirements for indoor air quality credits.

Environmental Performance:

- The building façade uses extensive amounts of glass to harvest maximum daylight. Additional elements such as deep steel Pergolas, and stainless steel mesh have been aesthetically incorporated as the second skins, to reduce thermal gain.

- Vertical fin elements downsize the low-angle sun and prevent glare.

- Reinforced concrete from the finish wall on the front façade obstructs the view into the service areas.

QUICK FACTS:

- Project: Lupin R&D Centre

- Location: Pune

- Architect: Venkataramanan Associates (VA)

- Land area: 19 Acres

- Built-up area: 330,000 sft.

- Project completion: 2016

BASF Green Leaves Project Mumbai

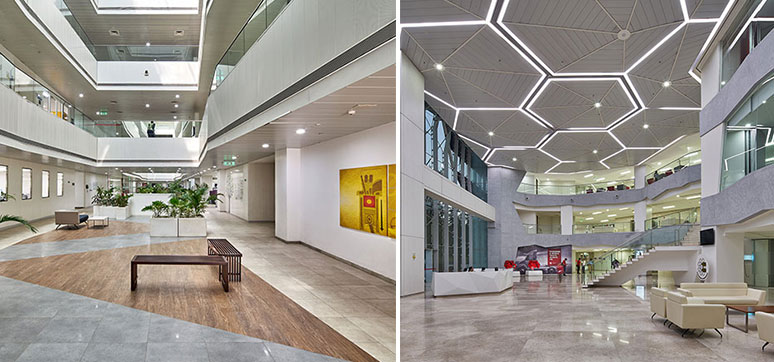

The Green Leaves project for BASF required redeveloping an existing building into a world-class research facility. The new innovation campus is a collaborative space housing scientific and technical laboratories, modern offices, a full-scale auditorium, a cafeteria, and other employee amenities.

The structure follows an open plan, offering interactive spaces to encourage communication and collaboration among the users.

The interior spaces follow a contemporary style with minimal lines and bursts of colour, defining the various spaces within the building envelope. A glass-roofed central atrium lends insular spaces on every level with animated balconies looking inwards.

Designed to achieve a LEED gold rating, the building incorporates several sustainable features such as a secondary façade to minimise solar heat gain, energy-efficient LED lights, rainwater harvesting, a reflective roof with photovoltaic panels, and a windmill to generate renewable energy.

QUICK FACTS:

- Project: BASF Green Leaves Project

- Location: Mumbai

- Client: BASF

- Architect: Venkataramanan Associates

- Completion date: 2014

- Completion date: March 2017

Cummins Technical Centre Pune, India

Cummins Technical Centre India is planned on a 16-acre site, which is part of a larger 67-acre campus owned by Cummins in Dahanukar Colony, Pune.

The existing site included a research & development building complete with test cells, laboratories, and offices. The design brief stressed demolishing all but the test cells.

As a global leader in engines, Cummins demanded the architecture of its new research facility to be a carrier of the brand’s high standard of excellence. Keeping with the requirement of retaining the test cells, the entire facility was planned as one cohesive unit encouraging movement across departments. The test cells were thus designed at the core of the building, while offices and laboratories surround them.

The external façade of the building reflects Cummins’ vision and follows a futuristic approach, pertinent to the high-tech environment. Featuring a 120,000 square-foot VS1 façade of glass and terracotta, the geometrically complex wall is the largest faceted wall in the world. Concrete columns form a structure of slanting surfaces on the façade, with grey tile cladding on the support and strips of glazing in between.

The main reception area is expansive enough to accommodate the movement of up to 2000 people at a time. An information desk, an experience centre for visitors, rooms for vendor meetings, visitors’ lounge areas, a small pantry, and restrooms are some of the facilities provided in this area.

A canopy, made of aluminium composite panels and clay tile cladding, covers the main reception area. The main reception and the two southern receptions to the facility have air-locked entrances freeing the environment of dust and sound.

Green spines run across the building, adding a touch of natural freshness, and form an integral element of the building. These spines are landscaped at the ground floor level and pedestrian walkways are planned around them. Skylights further grace this atrium and the rest of the office with ample natural light. The duality of a dynamic exterior façade coupled with minimalistic interiors is reflective of Cummins’ corporate social image and value.

QUICK FACTS:

- Project: Cummins Technical Centre – India (CTCI)

- Location: Dahanukar Colony, Pune

- Architect: Venkataramanan Associates (VA)

- Land area: 16 Acres

- Built-up area: 740,000 Sq ft / 68,687 Sq m

- Commencement of the project: 2011

- Completion of the project: 2018