Tall buildings continue to play a significant role in meeting our housing and workspace needs with high-rise curtain wall systems being one of the most recognizable components of today’s tall buildings. But along with this has come the increasing importance of passive fire protection solutions playing a vital role in these buildings, mitigating the effects of fire, saving lives and property. Passive fire protection solutions such as firestops are crucial to prevent the passage of flames and noxious gases from one compartment floor or room to the next.

Fires in high-rise buildings can generate large quantities of smoke that tend to spread vertically throughout the building, even if the fire is contained in one room. Smoke travels up to 130 meters every minute and whilst most people can easily move at this rate in normal circumstances, the majority of survivors of fires stated that smoke restricted their ability to see to no more than 4 meters.

When the gap/cavity at the perimeter edge between the floor and curtain wall is not properly sealed, flames and smoke can spread vertically to higher floors, and horizontally from one room to the next. Addressing these gaps/cavities by properly installing firestops maintains the floors’ fire compartmentation of the building. This delays vertical smoke spread and reduce the risk of smoke-related injury in the upper floors of the building, and adjacent rooms.

Firestops – A Safer Solution

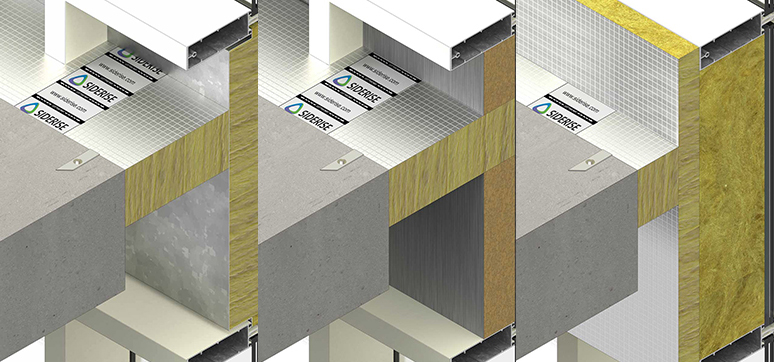

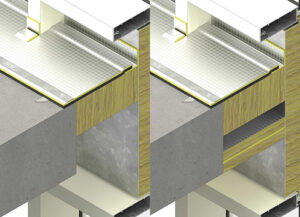

The perimeter barrier firestops seal the gap between the edge of the compartment floor slab and the external curtain wall. Due to project designs and site tolerances, this linear gap can be variable, so the firestop system used needs to have a degree of ‘dynamic’ movement capability – compression and recovery – in order to accommodate serviceability movement and more significant movement under fire load. It’s critical the firestop system does this in combination with the primary functional requirement, which is to maintain continuity of fire resistance between the compartment floor and the external wall. The installed firestop system needs to match the same period of fire resistance as the compartment floor.

All firestop systems need to be tested to two criteria – Integrity and Insulation (EI).

Integrity (E) refers to the ability of the system to prevent the passage of flame, smoke, and combustible gases either through and around the material or through joints in an assembly; while Insulation (I) refers to a measure of the increase in conducted heat transferred from the exposed to unexposed surfaces of 180°C rises above ambient. These two criteria are critical in the development of curtain wall perimeter firestop products. The most effective products combine a number of material features – density, thickness, resin content, fiber structure, and controlled compression – which together determine the resistance properties.

When looking at the Integrity (E) criteria, the material chosen must be impervious to the transfer of flame and gases, easy to install with minimal site management and accommodate all real-world requirements at interfaces, joints, and details. In order to meet the fire and smoke stop requirements in all external façade applications, Certifire Approved perimeter barrier and firestop systems offer an unrivalled combination of fully-qualified performance, practical installation, and service benefits.

The principal function of these systems is to maintain continuity of fire resistance by sealing the gap between the compartment floors or walls and external curtain walls horizontally and vertically. These systems can offer fire-rating options ranging from 30 minutes to five hours and accommodate void widths up to 1200 mm. In addition to providing an effective seal against the passage of smoke and fire, the products can also function as an effective acoustic barrier and plenum lining.

Key Design Considerations in Firestops Installation

The firestop should have test evidence to show that it is capable of accommodating the movement of a façade. It is imperative that the installed seal is able to function effectively with due regard to all designed movement serviceability limits. Curtain walling and cladding façade systems will deflect due to positive and negative wind loads as well as occupational live loads. These criteria are covered by EN 13116:2001.

Typically, a project may stipulate that the curtain walling system may have the following allowable deflection limits: Under the declared wind loads the maximum frontal deflection of the curtain walling’s framing members shall not exceed L/200 or 15mm, whichever is less when measured between the points of support or anchorage to the building’s structure in compliance with EN 13116. (Extract from EN 13830:2015) These factors may inevitably combine to preclude the suitability and therefore, use of certain systems e.g. high-density material slab products.

Perimeter barriers must be installed to provide horizontal compartmentation at every floor level. Vertical cavity barriers should be provided as a minimum to fall in line with any compartment wall and more frequently if dictated by the fire strategy of the building.

Products should be fitted tightly around all bracketry to restrict the passage of smoke. Where there is potential for gaps, the product must be sealed with a sealant that carries the same fire insulation and integrity rating as the perimeter barrier. All installations should be in accordance with manufacturers’ instructions and where fixing brackets are required these should be fitted and spaced in accordance with a certified fire test report. Products used for fire safety installation should carry an independent third-party certification in order to ensure that the product supplied is the same as that tested.

The gap between the slab edge and the façade is often a weak point acoustically. Any products used to improve the acoustic performance must not contribute to the fire load or inhibit the performance of the perimeter barrier.

The Local Code

The UAE Fire and Life Safety code of Practice has by far been the most comprehensive documentation and gives a clear route to product compliance and project requirements. The 2018 code highlights the specifics in relation to the performance requirements for slab edge perimeter barriers and the spandrel panel performance requirements. the document also clarifies the requirements of cavity barriers under the external façade assembly requirements with recommendations of the type of cavity barriers to be used. The cladding manufacturers have adopted the system test approach which includes the cavity barriers within the large-scale test of NFPA 285 or BS 8414 Part 1 or 2.

Seal the Voids and the Cavity

At the $160 million Vida Residence, moving towards completion at the Downtown Dubai in the UAE, fire safety was paramount in a development that houses residential apartments with a total of 60 Floors with unitized curtain wall and GFRC external cladding. With both vertical and horizontal fire compartmentation requirements, the specification of SIDERISE CW-FS 120 firestops provided the contractor Reem Emirates Aluminium with a one-stop-shop solution that could maintain a fire and smoke seal in one product. The project also had a requirement of sealing the cavity on the external façade assembly of GRC. The specification of Siderise CHCB provided the contractor Terrazzo LTD

Throughout the application, SIDERISE provided comprehensive support including drawing assistance, liaison with the authorities for approval, installation training and periodic site inspection, and assistance to key stakeholders in the project. Whilst specifying the correct product is vital, the quality of installation is equally as important. Contractors installing life-saving measures such as perimeter barriers and firestops must have adequate training on the particular manufacturer’s products and be qualified to install them in the first place. When it comes to saving lives and protecting businesses and property, a well-designed and installed system can make a difference.