Curtain walls are one of the most prominent features in modern buildings. They are placed on the surface of a building, forming a barrier between the interior and exterior of the building structure and act as a protective shield. Its main purpose is to keep air and water out of the building and is subjected to weathering actions like wind, sunshine, frost, etc. In this cover story, experts from the industry, including architects, façade consultants, builders, developers and manufacturers of important façade components explain the characteristics of an ingenious and well-designed curtain wall, different types of curtain wall systems, the need for performance tests, challenges associated with erecting of curtain wall systems, reason for failures, common faults found in such façade systems and solution for the same.

Characters Of A Well-Designed Curtain Wall

Glass curtain wall systems are extensively used in modern construction. Curtain wall systems are typically designed with extruded aluminium framing members, although the first curtain walls were made with steel frames. The aluminium frame is typically in-filled with glass, providing an architecturally pleasing building, offering effective daylighting and reducing solar radiation, says Ar. Balaji Gunasekaran, Project Manager Associate at KGD Architecture. While designing a building, the curtain wall system should be well integrated to suit its functional and habitable requirements, points out Ar. Sandeep Shikre, Founder & Principal Architect, SSA Architects.

The curtain wall has to be coordinated with the structural grid of the building whereby every micro aspect, such as vertical and horizontal divisions, size of panels, junction details, termination details at the rooftop and bottom level, etc. are well addressed. Curtain walls should not be an afterthought, it should be an integral part of the design.

Anupam De, Principal Architect, Anupam De & Associates, the primary purpose of a curtain wall (besides the aesthetics) is to create a building envelope, which provides a total barrier to weather conditions. The curtain wall system must carry the required loads and should prevent the collapse or excessive deformation of the structure. It should also be strong, and stiff and should withstand variation with temperature and time, adds Ar. Vivek Bhole, Founder & Principal Architect, Neomodernarch.

Ar. Abhishek Bij, Partner and Lead Designer, Design Plus Architects states that all envelopes should be resistant to water penetration, should control air leakage and resist wind loads, apart from providing the desired aesthetics. A well-designed curtain wall caters for minimum heat gain inside in the case of tropical climates and minimum heat loss in case of colder climates, says Shabbir Kanchwala, Senior Vice President, K Raheja Corp.

Curtain wall systems are best suited for buildings, considering technical, functional and visual aspects, says Rajan Govind, Director, BES Consultants. He adds that a well-resolved design (not just for typical areas), properly detailed at all interfaces, is able to be implemented with good quality and finishes. Structurally robust designs of curtain walls use fewer materials, yet offer good structural strength with optimised engineering designs.

Structural Strength Of Curtain Wall Systems

The structural performance of curtain wall systems has to be meticulously analysed and designed to fulfil structural code requirements because façades are subjected to strong environmental actions, says Dinesh Dubey, Director of Operations, Turner Project Management India Pvt. Ltd. In addition, as a second design step, by applying advanced finite-element analysis schemes and taking into account structural design criteria, an optimal structural design of the glass curtain wall system has to be carried out to achieve cost minimisation; analysis is also needed to fulfil structural integrity and serviceability requirements, he adds.

A good curtain wall system does not carry the floor or roof loads of the building, says Dubey. The wind and gravity loads of the curtain wall are transferred to the building structure. Glass curtain wall systems are designed with high-efficiency properties, the most important are a high strength-to-self-weight ratio, serviceability requirements, recyclability of the constituent parts as well as transparency and overall aesthetic characteristics.

While designing and installing curtain wall systems, three principal considerations have to be taken into account: performance, appearance and economy. Ar. Bhole and Dubey point out that in curtain wall systems, these requirements are closely connected to the form and the position of the supporting metal structure and anchoring system to the building frame. Although these systems are secondary structures of the building, they have to be effectively designed to safely resist the variable actions of wind and thermal loads acting on the building façades. In addition, any other load combination case, such as seismic action, should be meticulously considered to maximise structural safety and minimise any hazards to humans.

Kapil Chikodi, Business Development Head, Glass Wall Systems opines that it is very important to start with the structural calculation of the design and system. “We do a detailed calculation of the material to be used, the weight of the material, texture, height and dimension of the building. After analysing all these factors, we come to the conclusion that which profiles can be used in the project. Such calculation ensures that the system is safe to go as a structural component in the building,” he added.

According to Ar. De, the structural strength of the curtain wall is key to addressing its dead weight, wind and seismic forces. While many parameters play a role in structural strength, essentially low-rise buildings are affected by seismic forces and tall buildings by the wind. Besides the codal provisions/standards governing the curtain wall design, for tall buildings, it is necessary to do a wind tunnel test to determine the forces on various faces of the building, which helps the façade consultant in addressing increased wind pressure zones by means of inserts in the standard system.

A method used to determine forces on the façade is by means of a CFD analysis. Adding to this, Kanchwala says, the wind load at all stages of the building should be levelled. It reduces the overall sway of the building, thereby making the structure more secure.

Types Of Curtain Walls

There are two basic types of curtain walling installations: stick and unitised. In either stick or unitised systems, curtain wall provides superior structural strength. The entire fenestration system essentially “locks” together, providing excellent protection against high wind loads and earthquakes, states Ar. Bij. Ar. Gunasekaran from KGD.

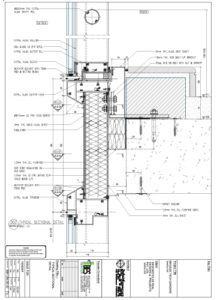

Stick systems are installed on-site, component by component. The vertical mullions and horizontal transoms are installed on MS or aluminium brackets which are anchored to the columns/slabs. Here, cut-to-size glass is fixed on the grid work with pressure plates (the glass is held mechanically). The cover cap snaps fit on the pressure plates for an aesthetic look.

In the above system, 90 per cent of the work can be done at the site, explains Ar. Gunasekaran. This means that a building has to be unoccupied during refurbishment. “Stick systems allow on-site adjustment, but the performance of the systems is dependent upon the quality of the installation, which often happens in uncontrolled conditions. In conclusion, stick systems are economical, however, slow to assemble and, hence may not suit certain fast-track projects. They are generally used for low-rise structures, says Ar. Bhole. Scaffolding from outside is required for this system. It is not aesthetically pleasing since the major quality of the work is done at the site.

Unitised curtain walling systems are installed as a series of factory-assembled frames, usually with interlocking mullions and transoms. The glazing panels, spandrels, and seals are applied or prepared in the factory. Unitised systems are used where the movement or deflections in a building are such that a stick system is inappropriate. The benefits are the speed of installation, minimal on-site labour, and lower installation costs. However, these are obviated to an extent by the increased storage and shipping costs, the need for very careful site handling, and the requirement for expensive lifting equipment on site notes Ar. Bhole.

Unitised systems are popular because they eliminate or reduce the need for on-site sealing, therefore making them less reliant on standard on-site workmanship. They do not require decanting during refurbishment contracts. In conclusion, unitised systems offer the benefits of factory fabrication in a controlled environment and very rapid assembly on site. However, they are generally more expensive than stick systems and require longer lead times. They are mostly used for high-rise structures.

The semi-unitised system is a hybrid version of the unitised system and stick system which could be mid-range in cost. The system involves horizontal breaks and is normally recommended for low and mid-rise structures. It is a combination of on-site stick-type cladding and off-site prefabricated panels. Both are brought to the site, cut to size as per site measurements and assembled.

The execution of this system is a challenge. In this type, if any glass panel is broken, the re-instalment is easier and faster. It could be adjusted even when there is defective construction in the floor-to-floor height. It is easy to transport more distance since it could be cut to pieces. It needs scaffolding for installation.

Advantages Of Unitised Curtain Wall

A unitised curtain wall has several advantages. The fully glazed panels being made in controlled factory conditions have better quality. Dependency on the capability of the site erection team is greatly reduced.

The erection of unitised panels does not require scaffolding and is much faster than the stick system. Panels are erected floor to floor by interlocking male and female mullions, whereas in the stick system, the aluminium grid is first installed, a post which glazing is done on-site with pressure plates and caps.

Ar. Anupam De, Principal Architect, Anupam De & Associates

Reasons For Selecting Stick/Unitised/Semi-Unitised Curtain Wall System

The decision to use a particular system depends on the design intent of the façade and the economics of the project, both in terms of time and cost, point out Ar. Bij and Chikodi. However, stick built is optimal if there is little repetition among components or when there are certain complex façades like three-dimensional façade, also in case of recessed windows with no continuity in the façade. Unitised is optimal if apart from repetition, time is the primary essence, says Kanchwala.

Dubey adds that the unitised system can be installed in a third of the time of a stick-built system. This system is well suited for cases where there is a large volume of prefabricated unitised panels required, and where there are higher field labour costs. Dubey says that it also needs a significant amount of space for the installation and storage of material on the site. “Largely, we have graduated to a unitised curtain wall in most projects. Moreover, unitised curtain walls are seamless and continuous in nature which works better for longevity and has high resistance to water and fire. The system is essential for all high-rise structures above 100 m”, says Ar. Shikre.

Types Of Weather Tight & Eco-Friendly System For Curtain Walling

There are three basic methods of resisting all weather forces within a curtain wall system: with a front sealed, fully bedded curtain wall, with a drained and ventilated curtain wall, and with a pressure equalised curtain wall (or rain screen cladding), Ar. Bij explains. Front-sealed systems rely on the exact positioning of the glazing panels and perfect mastic seals or glazing gaskets to provide a totally weather-tight exterior shell.

They have obvious limitations since their effectiveness is totally dependent upon the quality of the workmanship at the time of installation and the longevity of the gaskets. These weather seals typically won’t last the life of the façade and will require regular maintenance and replacement over time.

Some aluminium curtain wall systems are still designed as front-sealed barrier walls. The long-term reliability of such seals is extremely weak and such systems should be avoided, highlights Dubey. Further, for a more aesthetic look, the option of open sealant concept is also widely used with the use of EPDM gaskets forming a barrier in selected aluminium extrusions to prevent water ingress, providing a better look, he adds.

The drained and ventilated curtain wall system is a water-managed system, incorporating drains and weeps from the glazing pocket, but no effort is made to create an air barrier for “zone glaze” each glass or spandrel unit, and therefore a larger amount of water is forced into the system and must be wept away, elaborates Dubey and Ar. Gunasekaran. Also, since no air barrier exists, the pressure differential between the glazing pocket and the interior may be strong enough to force water vertically higher than interior gaskets, resulting in leaks.

In pressure-equalised (PE) systems or rainscreen cladding, an outer rainscreen provides a protective barrier. Protected openings allow air ingress to a compartmentalised central cavity, which facilitates pressure equalisation. The principle of the system is that the air pressure in the cavity changes with the external wind pressure, thus eliminating the pressure differential across the external seal which would otherwise draw moisture, explain architects Bij and Gunasekaran.

Weep holes in a water-managed system function largely to drain water that enters the glazing pocket while weep holes in a pressure-equalised system function primarily as vents to allow air movement between the exterior and glazing pocket. Weeping of water is only a secondary function. For hole drainage, minimum openings of 8mm to 10mm are recommended, while drainage slots of at least 20mm by 5mm or 25mm by 5mm are the recommended minimum. The drainage can be either through the transoms or mullions.

PE rain screen systems provide the highest levels of resistance to air and water infiltration, with water-managed systems the next most reliable, says Dubey. In PE rain screen systems design, the inside face of the glass, the inside face of the glazing pocket and the interconnecting gasket or wet seal act as an airtight barrier.

The outside face of the glass, exterior glazing materials and the outer exposed face of aluminium framing function as a rain screen shedding water away. Between the exterior rain screen and the interior air barrier, a pressure-equalisation chamber is formed in the glazing pocket, which serves to reduce water penetration by eliminating (equalising) the pressure difference across the rain screen that tends to force water into the system. Minor amounts of water that may penetrate the system are wept harmlessly to the exterior, Dubey explains further.

Micro Climatic Studies

It is important that the curtain wall addresses the microclimatic

response and achieves desired human comfort and safety. This

can be achieved through detailed studies listed below:

-

BBVA Bancomer, Mexico by Turner Project Management India Pvt. Ltd. Wind tunnel analysis –The lateral pressure of wind has a great influence on curtain wall design. This analysis enables us to adequately design extrusion and curtain wall systems to sustain the wind pressure, especially, for high-rise buildings.

- Seismic studies – Seismic behaviour is studied and the seismic tolerance coefficient is derived, which enables to adequate design of the expansion joints to sustain the tremors.

- Water flow patterns – Water drain channels are provided within the system to prevent the rainwater from entering the interior.

- Dead load – Additional dead loads imposed on the curtain wall, such as sunshades, must be accounted for in the design of the curtain wall components and anchors.

- Thermal and acoustics – A detailed energy simulation study and survey of sound enables us to select the double-glazed units and the combination of glass with respect to its performance, u-values, shading coefficient, etc. The extrusions are coated with Polyvinylidene Fluoride (PVDF) for thermal comfort. Details are worked out to ensure adequate acoustics.

Thermal loads are induced in a curtain wall system because aluminium has a relatively high coefficient of thermal expansion. This means that over the span of a couple of floors, the curtain wall will expand and contract some distance, relative to its length and the temperature differential. This expansion and contraction are accounted for by cutting horizontal mullions slightly short and allowing a space between the horizontal and vertical mullions. In the unitised curtain wall, a gap is left between units, which is sealed from air and water penetration by gaskets. Vertically, anchors carrying wind load only (not dead load) are slotted to account for movement. Incidentally, this slot also accounts for live load deflection and creep in the floor slabs of the building structure.

(As told by Ar. Sandeep Shikre, Founder & Principal Architect, SSA Architects, and Ar. Vivek Bhole, Founder & Principal Architect, Neomodernarch)

Principles Used In The Design & Performance Testing Of Curtain Walling Systems

According to Govind and Kanchwala, performance testing of systems is mainly carried out to verify the structural and weather performances of the system. Often curtain wall systems are customised for particular project requirements due to variable requirements, hence the designs are verified within laboratory conditions to test for various aspects like air, water, structural and seismic.

Any curtain wall system needs to be designed for various parameters including, but not limited to, air permeability, water tightness (static/dynamic), wind, impact resistance, seismic, etc. These need to adhere to the relevant codes (ASTM/BS, etc.) being used for the same. Besides the general system being tested, the operables (windows) also need to be designed and tested. Based on the inputs received from the wind tunnel or computational fluid dynamics (CFD) analysis, the designed system is erected at a test site and needs to be physically tested for all the parameters for the highest wind condition, articulates Ar. De.

Wind patterns: According to Ar. Bij, for any façade design, it is important to understand the patterns of wind over a building. When the flow of air (wind action) impacts a building, pressure is exerted and the airflow changes across the surface of the façade, causing a pressure differential.

Down draughts are created when the wind strikes a building, resulting in an increase in wind speed near the ground. Vortices are created as air flows along the roof, or is funnelled to the base of the building, which creates high suctions at the edges. Sharp changes in direction, such as parapets and corners, give rise to high local suctions (separation). Wind speed can increase and change direction, particularly at the base of tall buildings. Tunnels and openings through buildings also produce funnelling effects.

Architects

The principles for wind loading are as per Indian Standard IS:875 (Part-3) which gives wind forces their static and dynamic effects. This needs to be taken into account while designing buildings, structures and components. All building designs and structures consider a regional basic wind speed having a mean return period of 50 years, adds Kanchwala.

Wetting Patterns & Water Tightness: The building must provide a total barrier to keep out rainwater, points out Ar. Bij. Three factors that cause water leakage are water, openings and forces. Eliminate any one of them, and there will be no leakage. However, rain is usually accompanied by wind. It is therefore not possible to design buildings that are completely shielded from the effects of water. This is why a dynamic test is carried out when systems are performance tested.

There are a number of openings in a façade, including vertical expansion joints, the glass perimeter and gaps in gasket lengths. Water flows down and across a façade under wind action until it hits projections. It then runs down to corner areas – the position of most joints and openings. Joints or openings also occur between different adjacent materials or similar materials when dictated by fabrication transport or handling needs. Even where joints are required to be sealed, it is difficult to ensure that this is completely effective.

There are no design criteria for preventing water tightness, observes Kanchwala. The sections to be used in curtain walls are selected to ensure there is no water ingress. There is performance testing for various static and dynamic water penetrations confirming to ASTM E331 & AS/NZS 4284 for 15 minutes. The water ingress is measured from inside to ascertain KPa.

The Basic Tests:

• Air infiltration test

• Water penetration test

• Structural load test

The Additional Tests:

• The dynamic water penetration test

• The seismic test

• The thermal cyclic test

Softwares Used For Building A Perfect Curtain Wall

With the help of various 3D design tools and techniques, it is now possible to make any complex design a reality. These techniques are also helping in better and faster understanding of designs and reducing communication gaps. As there is always room for improvement, reaching a perfect solution is an attempt. The use of the following latest software is important as it helps in analysing the various inbuilt details from the study and execution point of view.

- REVIT/Building Information Modelling (BIM) – helps in placing the associated services and accessories in the façade and gives more insight and tools for efficient planning, designing and construction.

- Rhino – helps architects and façade engineers to visualise and derive an adequate strategy while focusing on algorithms and parameters. It also helps to design curvilinear, multifaceted and flamboyant shapes.

- eQuest – helps in energy modelling to identify energy performance

- FP façade software – helps to design curtain walls.

- Visual Doe software – helps to generate energy modelling for glass façades in-turn balance the heat and light transmission into the façades

- STAAD Pro – for the structural adequacy

- Inventor and Grasshopper – for the complex façade or the algorithm façades

- Athena or Softech – curtain wall-specific software that is readily available

- Design plugins such as Weaverbird or Panelling tools within Rhino/Grasshopper

Importance Of Performance Testing

A timely and well-planned façade performance test ensures the safety of the public and occupants of the building by identifying and ensuring structural and seismic stability. It is necessary to evaluate and validate the design of the façade, also to identify and point out fabrication errors, and air and water leakage if any. It helps in rectifying all faults before final production, saves cost and time, and at the same time ensures a quality façade.

There are also instances of challenges faced when the façade design is very complex and the building is very tall, points out Chikodi. Even when planning a specialised and customised design, it should go for performance testing to determine the behaviour and pattern of the system, adds Chikodi. Ideally, any façade should have performance testing, unless it uses a standard pre-tested proprietary system, “However, for tall buildings and large projects, it is a must. We are following this for our projects,” he states.

Performance tests are carried out in special laboratories called Performance Monitoring Unit (PMU), whereby wind resistance is tested by inducing artificial wind pressure, the water jets are sprayed to ensure water tightness and the fire is induced to evaluate the fire resistance, says Ar. Shikre. Dynamic performance tests are carried out to ensure the curtain walling system performance and figure out the faults and fix them with solutions, adds Ar. Gunasekaran.

According to Govind, performance testing is recommended for new designs, however, the performance (laboratory-based) testing alone will not guarantee defects-free or flawless works.

Testing is one of many other ways to control the designs and implementation, and there are many other aspects to be considered as a holistic approach. If not properly planned, states Kanchwala, a poorly structured curtain wall can lead to water leakage and deformation of the lower parts of the curtain wall due to inadequate support along with inadequate waterproof and steam-tight barriers. It can also cause disturbing, unpleasant sounds.

Most commonly experienced performance irregularities often result in complete replacement or expensive restoration/maintenance activities for the systems. Therefore, the performance tests need to be established at the design phase of each project separately, adds Ar. Bhole.

Ar. Gunasekaran says that at the start of a project, architects should work closely with façade consultants and contractors so that the design intent of the façade is completely understood. Multiple interactions and coordination meetings provide a smooth ride which critical elements such as wind loads and seismic loads are addressed. A field mock-up is done to finalise not only the look and feel but also the quality of the curtain wall systems. During the construction stage, designers check and review quality at various milestones. The necessary tests are done and certificates are made available for the project, which ensures the glazing performance.

Curtain wall systems are sophisticated engineering solutions and at the same time expensive solutions. It is very important to design it with utmost accuracy and adequate skill sets. It definitely has to be in safe hands. If designed in the wrong way, it will be dangerous and hazardous. Of late, unfortunately, due to a cost-saving approach, inappropriate curtain wall systems have been executed that have created fire hazards. It is essential that the developers, architects and vendors give utmost importance to ensure that the design and safety meet the codal requirements without any comprise, warns Ar. Shikre.

Challenges Associated With Curtain Wall Systems

The prime responsibility of construction quality assurance of curtain walls lies with the fabricators and contractors. The best design will fail if not properly implemented, points out Ar. Gunasekaran. It is important that designers and owners ask for demonstrated proof of QA/QC measures. Curtain wall manufacturers and installers must develop QA/QC manuals to help standardise and streamline the quality control process. These manuals should include checklists of quality control and inspection points to be reviewed for every assembly fabricated and installed.

Misalignment of adjacent curtain wall elements can have serious consequences, elaborates Ar. Gunasekaran. Such misalignment is often due to errors in laying out the structural framing systems, but might also result from lack of coordination of building structure tolerances and curtain wall tolerances, or improper layout of imbeds to receive curtain wall anchors. In the case of coordinating construction tolerances, if the construction tolerance for the structural frame is +/- 1 inch over the height of the building and the tolerance for the curtain wall is +/- 1⁄4 inch over that same height, it is the curtain wall that will need to be adjusted to conform to the looser tolerance of the structural framing which needs to be taken care by the site team.

Leakage is the biggest concern in any curtain wall, adds Ar. De. Largely these occur due to lapses in execution or due to tampering of the system in interior fit-outs. These problems tend to increase in smaller projects where appropriately qualified contractors are not appointed by some clients.

Cleaning and replacement of glass are another challenge if there is no proper BMU (building maintenance unit). Many clients are not willing to incur many costs towards the same, which leads to problems in maintaining façades and addressing defects post-handover, opines Ar. De and Kanchwala.

Besides the challenges above, there are issues with the operable in terms of suitable hardware for the same. The limited number of hardware suppliers/product ranges restrict the design solutions. This is further complicated by motorised operable and recent regulatory conditions for fire safety. In general, there is huge room for improvement of quality in curtain wall production, transportation and erection. The industry needs to improve the skill sets, and SOP’s for QA/QC. Often one gives more weightage to completing a project faster, which tends to compromise on quality. Improper or substitute materials are used, resulting in faulty façade works and the building degrades quite faster and loses the building value within a very short period.

Sometimes, no attention to proper detailing and design is given in advance (pre-construction), and passed to the contractor. In such cases, the site team has to deal with problems. Design simplicity needs to be focused, on in situations, where designers try to push unrealistic or impractical designs without understanding the long-term issues or limitations, says Govind.

Challenges In Production And Installation Of Curtain Wall

- Compared with traditional manufacturing, a façade panel has a higher degree of customisation, which is reflected by not only different designs for different projects but also different façade panels even in a project, so fast and flexible production is required as needed.

- With the emergence of new materials and new technologies and people’s constant pursuit of different building appearances, façade fabrication becomes bigger in size and increasingly complex in shape, accompanied by increasing difficulties in field installation. In this case, if the delivery sequence and installation process are not well managed, the installation positions of façade panels may be confused, thus causing project delay and the waste of resources.

- What we need is an accurate data integration environment incorporating building design, detailed joint design, and field installation together covering a series of management activities, including façade fabrication production, positioning, detection, cost estimation, and risk control.

Design Problems That Afflict Owners, Architects And Developers

- Lack of awareness: It is often noticed that building materials are not selected on the basis of their constructability.

- Lack of data & research: The awareness of the impact of the material on the building performance and its efficiency is a very important criterion. Since there is no proper research and database available, architects and developers are abandoned from making informed choices about efficient building materials.

- Lack of initiatives: Many times, less importance is given to the selection of material.

- Trend-driven market: The pursuit of global technologies for advancement often leads to the direction of unsustainable development.

(As told by Ar. Vivek Bhole, Founder & Principal Architect, Neomodernarch)

Common Faults In Erection Techniques & ITS Solutions

Quality construction team & quality assurance/quality control: The best design will fail if not properly implemented. Experienced project managers, foremen, factory personnel, glaziers, ironworkers, crane operators and similar professionals are needed for a successful project, regardless of the type of curtain wall and installation method. Even with highly qualified contractors and sub-contractors, factory and field quality assurance and quality control are often not sufficiently planned or implemented. Experience shows that the factory and field foremen are some of the most critical members of the contractor’s workforce.

The quality control and inspection points: This has to be reviewed for every assembly fabricated and installed. To be effective, each prefabricated assembly should be given an identification number and its own individual QA/QC checklist. Not only will this help with the establishment of reviewable procedures, but it will force the manufacturer and the panel erector to implement and maintain rigorous self-inspection practices. Periodic factory visits by a qualified curtain wall consultant engaged by the owner or architect for any modular curtain wall project and for stick-built projects are essential where significant volumes of assembly are performed in the shop.

Careless erection techniques: Curtain wall modules are often large, heavy and awkward and require careful planning and implementation of protective crating, handling, transportation and erection. It is critical to have experienced curtain wall installers to perform the installation. Attempts to make up lost time for construction delays can result in damage to curtain wall components as crews rush to meet unrealistic production targets. Meeting the target substantial completion date means little if the result is a punch list of damaged items that require months to complete.

Shifting and handling of panels without adequate lifting equipment and the improper curing of structural sealant are some other faults, observes Kanchwala. To overcome these, a builder should select the right fabricator through the process of shop drawings. The methodology for erection and logistics should be kept in mind and there should be correct supervision to avoid any accidents or difficulties during construction.

Govind stresses the importance of pre-construction designs to be realized at an early stage. This greatly reduces site implementation problems. Advanced planning and following proper site sequences is critical. Good management systems and site monitoring with technical knowledge (not just labour management) will solve many problems.

With these potential problems, many designers are grappling to execute a well-designed efficient curtail wall. Therefore, it is becoming increasingly necessary to get curtain wall consultants to help identify performance issues and assess the risks that unusual designs might present. The challenges can be straightened out carefully with the assistance of consultants, who are actively engaged in the business of performing forensic evaluations of ageing and failed curtain walls. They are better equipped to access the merits of past successes and failures while helping to meet the owner’s expectations for more uncommon curtainwall designs.

The Most Common Types Of Failures In Curtain Wall Sections

Moisture damage: Damage from water infiltration includes the premature deterioration of the wall structure, finish damage, mold and mildew, and decreased interior air quality. Repairs from poor water protection are often expensive to fix but can be easily prevented in the initial design and construction of the curtain wall.

Moisture damage can be classified into two distinct parts. The first is water infiltration while the second is condensation. Water infiltration creates the largest potential for moisture damage in a building. Sealants are primarily used to prevent water penetration into a curtain wall; however, sealants can break apart. Poor adhesion can cause the sealant to break away.

The thermal expansion coefficient of aluminium is 2.5 times that of glass, the large relative displacements often cause sealants to break. A perfectly watertight curtain wall cannot be maintained by sealants alone. Sealants are not perfect as they break, pull away or cannot be installed correctly. The best way to avoid water damage is to have redundancy in water protection, by incorporating an in-wall drainage system along with careful consideration of a proper sealant.

Curtain wall sealants are only designed to last 10 to 15 years; therefore, regular maintenance and upkeep of sealants are a must to prevent damage. Condensation occurs when the temperature of the glass or aluminium frame in a curtain wall reaches the dew point temperature of the interior space conditions. Water forms on the surface of the glass or aluminium and can cause damage to the unit.

Basic design against condensation in ensuring the Condensation Resistance Factor (CRF) of a given curtain wall section meets the requirement of the space, which is based on the expected temperature and humidity of the space. A great way to prevent condensation in frames of curtain walls is to use thermally broken aluminium. Thermal breaking is when a piece of plastic is incorporated into the frame, which significantly decreases the heat flow in (or out) of a curtain wall. This reduction of heat flow raises the surface temperature of the aluminium and decreases the possibility of condensation on the aluminium. Another prevention, which can be incorporated in the design is limiting the amount of non-thermally broken aluminium exposed to the exterior.

Glass failure: Glass failure in curtain walls can be split up into several different categories. Nickel Sulphide (NiS) inclusions, thermal cracking, and damage from impact are the most common types of glass damage. NiS inclusions, also known as “glass cancer”, are imperfections incorporated in the glass when it is manufactured. NiS remains at high temperatures after the rest of the glass has cooled. After the NiS cools, the inclusions expand in volume and crack the glass. This effect is most commonly seen in the tempered glass. In order to stop NiS inclusions from cracking in a curtain wall, the engineer should consider not using tempered glass, or perform a heat soak test.

Thermal cracking of glass is another concern that the engineer should consider when designing a curtain wall. Large temperature differences in the glass cause high stresses within the pane, forcing the glass to crack. Thermal cracks are easy to detect because they are perpendicular to the frame and usually expand the whole window section, failures are more likely to occur when an absorptive coating is placed on the glass. These coatings are put in place to reduce the cooling load of the building but can come at a cost to the glass integrity because they absorb solar radiation and keep it stored in the glass.

The stored energy increases the temperature of the glass and can cause it to expand unevenly, creating a crack. The more effective (i.e., more sun absorbed) the more likely the glass is to crack. If the glass support allows some movement, the likeliness of a thermal crack occurring decreases slightly. In order to properly design for absorptive coatings, an engineer should consider the stresses that will be induced in the glass by the sun and the coating and see if the stresses will likely cause the glass to crack. Also, an engineer can specify the use of heat-strengthened glass, a stronger form of glass, which can take higher thermal stresses. Other alternatives such as a reflective, not absorptive, coating should be considered, if applicable.

Design and installation issues: in this case, engineers make decisions on curtain walls without understanding the full consequences or failure scenarios on the curtain wall or construction teams do not fully understand how to properly install the curtain wall. In order to prevent the failures, a structural engineer or other design professionals should be fully informed and experienced on-site. Also, construction teams should have a full understanding of the importance of proper installation of curtain walls. These types of failures can vary from improper installation of sealant which causes the building to leak, to collapses of curtain wall sections.

(As told by Dinesh Dubey, Director of Operations, Turner Project Management India Pvt. Ltd.)

Some Of The Common Faults In Erection Technique And Its Solutions:

- Fault: Unsealed mullion to glass joint; Solution: To be double-checked at the factory before delivering to the site

- Fault: Water ponding in curtainwall; Solution: To be tested at the factory and ensure drains are properly provided

- Fault: Curtainwall sill flashing not sealed properly; Solution: Contractor must ensure all the flashing is sealed with necessary silicon sealant

- Fault: Misalignment of mullion; Solution: Periodical check and quality control

- Fault: EPDM gasket cover missing; Solution: The erection team ensures that the gasket is installed

(As told by Ar. Balaji Gunasekaran, Project Manager-Associate at KGD Architecture)