Aluminium extrusion, being a cost-effective material, has become one of the most preferred choices in construction. Extruded aluminium materials are known to be the most versatile in application as well as in production. Aluminium is one of the most malleable materials and allows complex shapes, hence it can be used in various structures. It also allows more options in design without sacrificing the strength and durability of the end product.

There are numerous benefits the aluminium can provide to a building. The Middle East’s construction and building industry has adopted aluminium extrusion as an important material for their buildings. In this cover story, a few of the big players from the Middle East Extrusion industry have shared their views on aluminium extrusion as one of the most sustainable and versatile building materials in the region.

Benefits Of Aluminium Extrusions Used As a Building Material

Whether aluminium arrives on-site as part of a building element produced by façade contractors, or as a custom component designed to create a unique statement, aluminium extrusions find a wide range of applications in buildings. Fenestration, energy management, skylight and canopies, structural domes, and interior elements are some of the common applications for aluminium building products, says Hilal Mahdi, Commercial Manager, TALEX LLC.

There is a plethora of uses and benefits of aluminium extrusions in architectural applications. The malleability and corrosion resistance quality of aluminium along with its low density (about 1/3 of copper and steel) and high strength makes it an ideal choice for building applications. Moreover, aluminium extrusions can be produced in a vast array of shapes, colour finishes (powder coating, anodising, and wood finish) and its ease of fabrication with fewer tools makes it more favourable and economical.

Due to its long-term durability and high structural integrity, it offers several applications in commercial buildings, such as windows, doors, curtain walls, sunshades, storefronts, handrails, kitchens, etc., says Ibrahim Al Ghas, Managing Director, Arabian Extrusions. He adds that aluminium is a very sustainable and environmentally friendly material, and it is the third most naturally abundant element in the earth’s crust. Aluminium is also non-toxic and non-combustible.

Sustainable Characteristics Of Extruded Aluminium Building Products

Mahdi says, with this highly workable material, architects can create and choose shapes that yield functionality and aesthetics, while providing superior cost-effectiveness and sustainability (recyclability and high recycled content potential). Aluminium is 100% recyclable with high scrap value and can be repeatedly recycled, retaining the same material physical properties. 73% of all the aluminium ever produced is still in use today, and these figures are increasing as more segregation and public awareness is created.

Al Ghas has listed some of the sustainable characteristics of extruded aluminium building products, which are:

• Wide Choice Of Alloys: Different alloys have the physical and mechanical properties that can be varied in a wide range to satisfy the requirements of a large number of different applications.

• Design Flexibility: The extrusion process offers an almost infinite range of forms and sections, allowing designers to integrate numerous functions into one profile.

• Long Service Life: Aluminium building products are made from alloys that are weatherproof, corrosion-resistant and immune to the harmful effects of UV rays, ensuring optimal performance over a very long period of time.

• Hundreds Of Surface Finishes: Aluminium can be anodised or painted in any colour to meet a designer’s decorative needs.

•No Release of Dangerous Substances: The alloys and their surface treatments (either coating or anodising) and the materials used are all neutral.

• Air Tightness: Aluminium products are ideal, as they are not porous and their mechanical stability secures the highest performance throughout the years.

• Fully Recyclable: Aluminium scrap can be repeatedly recycled without any loss of value or properties

Upscale Technology For Better Extrusion Processes

Highly automated and flexible extrusion plants are capable of responding quickly, cost-effectively and energy-efficiently with the production units. More precision-engineered products are coming into the region to fulfil the ever demanding specifications.

“TALEX has the fully automated, integrated extrusion facility, which ensures traceability of all TALEX production stages. The facility provides aluminium products for the GCC and global market”, says Mahdi.

Al Ghas notes that there is continuous upscale in terms of technology in an extrusion process, improving quality and recovery.

New Technology Innovations And Advancements In The Aluminium Industry

Mahdi says, the extrusion process allows to take advantage of the qualities of aluminium and offers a large number of design options.

According to him, there are many changes happened in the past few years. He says, we have seen a plethora of changes in the recent years, which has positively enhanced the quality of aluminium products for various industries like automotive, aerospace, engineering and architecture.

He believes that the use of aluminium alloys in the extrusion sector has grown in the last decade. Aluminium extrusions are increasingly used in end-user sectors, such as construction, transport, electricity, machinery and consumer goods due to the strength, flexibility, durability and sustainability they offer. Extrusion plants are betting on modernization and use presses with higher pressure forces, and integrated machinery for pre-finished products.

Challenges Faced By The Industry After The UAE Fire & Life Safety Code

The UAE Fire and Life Safety Codes aim to raise the standards for supplemental materials and reduce the cladding’s flammability to zero. Buildings completed prior to the strict regulations should be audited individually to identify the risk specific to each building and must meet the new code requirements when it is time for their maintenance, says Mahdi.

Mahdi opines that there are a variety of other fire safety issues that must also be considered, including non-flammable solid aluminium cladding.

The Challenges Faced by the Industry, Post the UAE Fire & Life Safety Code :

• Accountability: There is plenty of information in the new code documentation, but what matters is the enforcement of it. The idea behind accountability is trying to solve that enforcement issue.

• Design: All issues can be pre-empted with good design and good design can come from a consultant.

• Budget: Some maintenance contractors will quote a very low price as compare to others, but it all depends on the quality of work they will do in assessing fire safety.

• Over-engineering: As far as over-engineering is concerned, there is too much content available in the market from the developed nations or the developed economies in terms of regulations and standards.

We are just adhering to the best possible solution. Over-engineering and supplying a product that is not commercially viable or is over-specified for the building, does not serve the purpose. (Ibrahim Al Ghas, Managing Director, Arabian Extrusions)

Benefits Of Green Building In Building Designs

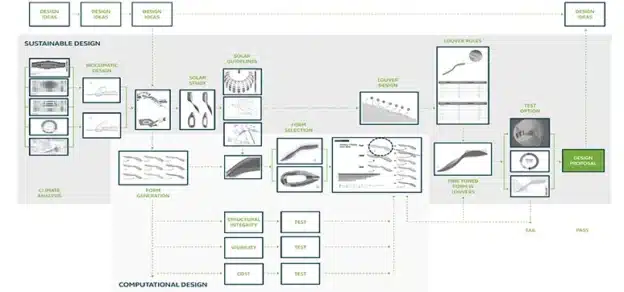

Mahdi says that the aluminium elements in construction can contribute widely from design to full life cycle of building, integral PV strips, and PV-faced louvers and sunshades (which can be angled to generate power equivalent to rooftop panels). Aluminium-framed products can meet the thermal performance requirements of green building codes in every zone with the increased use of thermal barriers.

Aluminium is the versatile, recyclable, and sustainable material that makes it one of the important materials to be used in buildings to get the LEED rating. Aluminium also offers high energy efficiency and environmental sustainability, hence it is also known as a greener building product.

The Building And Construction Applications And Innovations Using Aluminium Extrusions

Mahdi highlights some of the building and construction applications and innovations that can be done by using aluminium extrusions:

• Fenestration: Window and door applications (including hurricane, forced entry, tornado and blast-resistant systems), and storefronts and curtain walls

• Energy Management: Sunshades and louvers, light shelves, photovoltaic (PV) panel framing and mounting, and rain screen mounting

• Skylights and Canopies: Sunrooms, atriums and enclosures, observatories, gates and archways

• Structural: Bridge decks, space frame systems, garages and parking covers, and geodesic domes & structures

• Interior Elements: Panel systems and cubicles, elevator cab framing, light housings and grids, demountable interior walls, railing systems, and decorative screens.

According to Al Ghas, aluminium extrusions can be used in various building and construction applications, such as:

• Commercial Windows & Doors: Aluminium windows and doors provide energy efficiency, structural integrity, resistance to air & water infiltration, aesthetics and long term durability.

• Curtain Walls & Storefronts: Aluminium is used for making of curtain walls and storefronts due to high strength-to-weight ratio, glazing and wind load capability, maximal indoor daylighting, design flexibility, ease of fabrication, maintenance, finishing options, thermal capabilities, etc.

• Skylights & Sunrooms: Aluminium extrusions are also commonly used in skylights and sunrooms.

• Photovoltaic Cells: Due to high strength and lightweight, resistance to humidity and temperature, corrosion and thermal conductivity, they are used in framing hardware of photovoltaic cells.

Holistic Applications Of Extruded Aluminium Products To The Whole Building Design Concept

Al Ghas believes that the concept of whole design combines the synergies from an integrated design approach and an integrated team process to work together throughout the project, to evaluate the design cost, quality-of-life, future flexibility, efficiency, overall environmental impact, productivity, and how the occupants will be enlivened.

All the integrated components work together to provide the benefits of reduced energy consumption, cost savings, improved indoor environment for occupants, and a sustainable high-quality building that performs for decades.

Al Ghas adds that the whole building design allows design flexibility, for example, thermally broken aluminium window frames may be used in combination with increased insulation, HVAC efficiency, ambient lighting, high-tech glazing, ventilation and shading devices, providing many more options in designing energy efficiency in the overall building envelope.

Architects, designers and building engineers are now striking a new balance between performance and aesthetics. The sun-tracking aluminium extruded shadow voltaic louver system helps in contributing to the building’s electricity requirements.

Challenges Faced By Commercial Buildings In Terms Of Sustainability & Increased Security

Mahdi says that there are various architectural challenges faced by commercial buildings, which includes: reducing energy and resource consumption, increasing code adoption and enforcement, increasing stringency of the energy codes, and growing demand for sustainable buildings. He adds, a greater focus on occupant health, LEED® certification and impact resistance requirements are also the major challenges faced for commercial building performance.

According to Al Ghas, today’s architectural and design challenges involving overall commercial building performance are:

• Reducing energy and resource consumption

• Energy codes and guidelines are becoming more stringent. Each state or city has building codes that also include requirements for building energy efficiency. This include requirements for the thermal performance of windows, doors and skylights, etc.

• The demand for commercial green buildings is increasing globally to curb greenhouse gas emissions and increasing overall energy efficiency while lowering heating and cooling costs.

• Compliance with LEED (Leadership in Energy and Environmental Design) specifications continues to grow

• Many states mandate the use of impact-resistant products in wind-borne and earthquake-prone regions.

• Achieving high security, i.e. bullet-resistant glass, high-security entrances, etc.

Importance Of Thermal Barrier System For Extruded Aluminium

Thermal breaks are typically employed in applications such as exterior windows, doors or supermarket coolers to insulate the “cold” space from the “warm” space. The thermal barrier system reduces the heat transfer significantly and per capita energy consumption will be less for buildings. It allows design flexibility with greater structural integrity and combines dual finish options, says Mahdi.

According to Al Ghas, thermally separating extruded aluminium windows greatly improves thermal efficiency in the sash and frame, and vastly reduces thermal conductivity to energy-efficient levels. Thermally separating extruded aluminium windows allow aluminium’s many key properties to be utilised.

Al Ghas opines, when thermal barrier materials, such as polyurethane and glass fibre reinforced polyamide are used in conjunction with extruded aluminium framing, the resulting thermal efficiency in a window sash and frame are greatly improved. Manufacturers have been able to reduce thermal conductivity to a fraction of the original value.

The thermal barrier makes an extruded aluminium window, skylight, or door highly energy efficient, reducing heating and cooling costs substantially. The thermal barrier material acts as a barrier to heat flow from a warm interior to a cold exterior in winter, and blocks heat entering a building in the summer.

Current Status Of Domestic And Global Aluminium Extrusion Industry

The performance of the aluminium extrusion market in a region is observed to be closely associated with the GDP per capita of the geography. The increasing economy of a country leads to the development of a nation, urbanization and results into the rise-in demand for infrastructure along with demand for vehicles, says Mahdi.

Mahdi adds, as building & construction and automotive industries are two of the prominent end-user industries for aluminium extrusions, the GDP of a geography has a strong impact on the aluminium extrusion market.

There is a good potential for the aluminium extrusion industry in the domestic and global market. Construction activities are continuously in the upper trend in the domestic and global market, believes Al Ghas.

Upcoming Changes In The Aluminium Extrusion Sector

According to Mahdi, the aluminium industry will penetrate more into new verticals like industrial, aerospace, automotive, engineering and solar sector in coming years. Façades and fenestrations will be more energy-efficient and sustainable in the future. These factors will bring a number of changes in the aluminium extrusion sector.

Conclusion

The Middle East region offers a huge potential for the aluminium extrusion industry to flourish. In the Middle East, the architectural and building industries are the major consumers of the aluminium extrusion materials. The construction and building applications account for 87 percent of aluminium extrusion market. They are the key drivers of aluminium extrusion and they are also expected to fuel the growth in of the industry in future.