In an exclusive round of question and answer with WFM Mr. Varghese talks about the window and façade industry, his choices and the uphill journey of Sobha Group

Following are the excerpts –

WFM: Please tell the readers how you got into the

PV Varghese: I was working in Dubai for a construction company taking care of their cladding division when I got a call from Sobha Group. Mr. PNC Menon interviewed me and shared his vision of setting up a glazing and metal works division for Sobha Group as a part of their backward integration initiative. The association worked out and I moved to Bangalore to set up the same. Since then I have been part of the illustrious Sobha group.

WFM: So this division only does projects for Sobha’s in-house projects or have you diversified to other avenues?

PV Varghese: Actually not. In fact only 15-20% of SGMW revenue comes from in-house projects of Sobha’s real estate arm. 55% of the revenue comes from Infosys projects and rest 20-25% from other clients vis-à-vis ITC, Huawei Tech, Viacom, Dell, SKF, Raheja Group etc.

WFM: Kindly elaborate on your association with the Infosys group

PV Varghese: Around March 2001 Sobha had taken up Infosys Bangalore’s corporate block as a turnkey project. Infosys’s projects division was not too satisfied with the kind of service and quality they were getting from the façade contractors they were working with. That was around the same time the Glass and Metal Works division had started and we ended up doing glazing for the Bangalore project. Such was the satisfaction level of the authorities that we were immediately awarded the façade work for their Mysore campus. Since then, there has been no looking back and we are continuing to do all the projects for Infosys till date.

WFM: Now that so many options are available in the market vis-à-vis wood, aluminium, uPVC and now WPC, how do you make a choice? What are the factors that influence your decision?

PV Varghese: There are indeed various options available in the market, but when it comes to choosing the right material, we consider the functional requirement, aesthetic value, durability and finally, the cost. For villas having specific functional requirements, we prefer aluminium. I personally, I will prefer aluminium windows because of its high recycling value. The Un-plasticized Polyvinyl Chloride (uPVC) is generally used for low-cost residential buildings of a repetitive nature.

WFM: What factors do you consider while deciding on which kind of application to be used at a particular opening site, (casement, sliding, Slide & fold, lift & slide, tilt & turn, top hung, vertical slider, etc.?)

PV Varghese: Functional requirement, space utilization and aesthetics – these are the three most important factors we consider while deciding on the application to be used. The type of window used in a bedroom will definitely be different from one used near the staircase. In my view, I favour sliding windows when the window requires a grill behind it.

WFM: What is your take on the importance of the role of right fenestration in achieving system performance, optimum acoustic and thermal insulation as well as in achieving the desired aesthetics in a residential tower?

PV Varghese: Sound insulation, functional requirements and aesthetics play an important role in the selection of windows. Since the window sizes are smaller in residential spaces, thermal insulation often takes a back seat. The energy saving in residential projects, especially using windows, is not very significant. Hence, there is no particular requirement of using high-performance glass with insulation. However in cities like Delhi and Chennai, where summers can get intolerable and the temperature difference between inside and outside is considerable, double glazing arrangement provides both thermal insulation and sound insulation as an added benefit.

WFM: Talking about the safety requirements, people in residences generally ask for grills. Particularly in Mumbai which is a blot on the aesthetics of the windows. What are your views about that? Could there be other options?

PV Varghese: Today, lightweight safety grills are the best option available for the safety of the people inside a building as it ensures maximum protection against theft. Another option is to use laminated glasses with normal PVB or even with sentry plus, but cost becomes a cause of concern. With the advent of technology, various safety measures are available that give the residents the required security.

WFM: What is the criterion for choosing the glass in a typical housing project?

PV Varghese: Insulated toughened glass is the best choice for residential projects, especially for windows. First of all, the thickness of the glass needs to be selected as per the structural requirement. Important criteria such as the height of the building, window size and wind load are considered to arrive at the optimum thickness. Other important aspects such as the requirement of thermal and sound insulation are also considered. Finally,one can add tint to the glass to make it aesthetically pleasing.

WFM: Coming to execution, what do you think are the main hurdles/ bottlenecks in the Indian construction scenario when it comes to fenestration?

PV Varghese: It is important to deliver the right product at the right time to avoid any damage to the product. The quality of the products used is another cause of concern for many. There is a sequence that needs to be followed in order to ensure that the products are installed correctly. Due to tight project delivery deadlines, many tend to ignore this aspect. As a result, the final product such as doors and windows end up getting damaged. Also, it is important to protect the windows until handover.

Fortunately for us, at Sobha Group, our penchant for quality has always earned us laurels. We ensure that only the best quality materials are used to produce world-class products. We also make sure that the necessary procedures are followed at the time of installation to ensure that the windows and doors are damage-free to a large extent.

WFM: How do you see the fenestration industry evolving over the next 5 years?

PV Varghese: The industry is slowly gaining momentum. Clients today are demanding quality products. They are aware of key requirements as far as windows and doors are concerned. Also, the emerging façade consultants are helping the industry perform better.

WFM: do you think right fenestration can help in realizing a healthy Building? What measures do you take as an organization supplying quality windows and/or façades to help enhance the indoor environment?

PV Varghese: For façades, insulated and high-performance glass (double silver low-E) with proper shading elements on the outside will ensure effective fenestration. This will also help the building meet the statutory and green building norms. At Sobha Group, we take extra measures to ensure that an individual is comfortable at every point within a building.

WFM: Noise can be more detrimental to human dwelling than just being an irritant and distraction. How well are your windows planned to counter noise infiltration?

PV Varghese: Noise reduction techniques are factored into the design stage of a building. Our industry is still at a very nascent stage as far as this problem is concerned. A proper study should be done to understand the nature of noise created in the area and a proper system needs to be designed with an appropriate gasket system. Also, care has to be taken to select the proper thickness of the glass and also to select the proper process for the glass (DGU) laminated or both.

WFM: Is there a demand from the client’s side? Do they ask you to design the house so as to minimize the sound ingress?

PV Varghese: It is usually the hospitality sector that is particular about minimising sound ingress. We have seen clients in this sector engaging acoustic consultants for the selection process of windows that are capable of tackling noise problems. Except for residential projects near highways, which are provided with double-glazed glasses, there is no specific study or requirement for the implementation of acoustic norms.

WFM: In what situation do you deem it necessary to take extra measures to achieve a higher degree of sound insulation and what measures do you take to achieve the same?

PV Varghese: Buildings in flight path as well as those near highways and railway lines are most susceptible to high decibel (dB) levels.Hotels located in these areas have specific dB reduction requirements to ensure maximum comfort to the occupants. We at Sobha Group use the best possible solutions to ensure a high degree of sound insulation in these specific areas. For instance, the use of proper gaskets, DGUs with variable glass thickness or laminated glass or both; selecting the right system vis-à-vis triple barrier and/or thermally broken system etc. help in achieving optimum sound isolation.

WFM: What are your preferences when it comes to choosing a particular finish?

PV Varghese: I favour powder coating in white or light shades for better colour retention. There are some great choices available in the market that ensure excellent durability. Natural colour anodising of required microns is also a good choice. Although for a superior finish, one may use PVDF it’s not very widely used due to the lack of sufficient and credible vendors as well as the high cost of the material.

WFM: Please relate your experience where you feel the façade was a challenge.

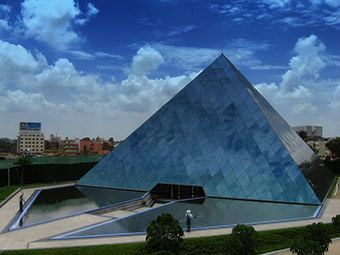

PV Varghese: recently we completed the façade work for Huawei. It was a 20,000 sq. mt. of ventilated tile cladding imported from china and an additional 10,000 sq. mt. of glazing. The client had initially awarded the contract to some other vendor, but he left them in a lurch. We came to their rescue and completed the feat in less than the stipulated time period. The client is immensely happy and so are we. Likewise, in another separate incident, at Infosys, there is a particular building in their Mysore campus called SDB 4 where the entire facade consumed about 1000 metric ton of structural steel, 10,000 sq. mt of structural glazing and 20,000 sq.mt of ACP cladding. It was such a challenging job and we completed the same in just 180 days. There have been various, and if you ask me, each project brings its own challenges and what drives us is the fervour to see them through start to finish.

WFM: What’s your message to the fellow industry people?

PV Varghese: I would just say – “be sensible and propagate the good values. Apply value systems in the industry. In spite of having so many talented and able façade contractors, our industry is not mature. We have to bring transparency into our work and ensure that the client gets the best. Our country is developing at a never before pace and it is just a matter of a few years that we shall be counted amongst the most developed nations of the world. Façade industry has t to play a part in achieving that dream.