The View Hospital in Doha, Qatar, exemplifies how media façades can not only be used to convey brand messaging or experiential artwork at a giant scale but can also be a key facet of an architectural concept. The View Hospital is located directly on the waterfront and this stunning location is referenced in the façade design with the help of LED lighting integrated into 4,000 sqm of glazing. This high-tech media façade system is a transparent glass, full media display, and structural building element all in one. It also fulfilled all prerequisite functional and design specifications from the design consultants.

When designing the building, the architects took the surrounding water as a defining element for the elegant glass façade. Measuring 8,000 sqm overall, it covers virtually the entire front of the slender, towering building, curving organically towards the riverbank.

Uniformly spaced, floral-like ornaments decorate the vast surface, while water seems to flow across the entire width in gentle undulations – a visual effect created by LED lighting that is integrated into the glass façade via liquid lamination. The building was commissioned by a Qatari company, Elegancia Healthcare, in collaboration with a US company, Cedars Sinai Medical Centre, to create a state-of-the-art centre for modern medicine.

Doha, the capital of Qatar, known for its ultra-modern buildings and forward-thinking design, became the focus of heightened public interest whilst hosting the FIFA World Cup at the end of 2022.

When the final match was played on 18th December, another high-profile event also took place, albeit an architectural one: the eagerly awaited opening of The View Hospital after several months of construction. The new high-end healthcare facility is located in the Al-Quataifiya district on the Lusail expressway, half an hour’s drive from Hamad International Airport. The location directly on the banks of a river estuary offers a picturesque view over the waters of the Persian Gulf and an outstanding view of Doha’s breathtaking skyline.

The developers and operators wanted to use the building’s architectural design to convey the high-end healthcare and state-of-the-art technology offered within. Following a competition inviting design proposals for the façade, the internationally renowned architectural firm, Chapman Taylor, was declared the winner and commissioned to develop the unique design.

The first LED glass panel was installed in mid-April 2022 and installation was completed in an astounding 3 months. The glass panels were airfreighted to Qatar where 60 specialised personnel, along with 200 workers, made this conversion project a success while adhering to the highest quality and safety standards. From design, production, shipping, and installation on site, the project was executed within 9 months.

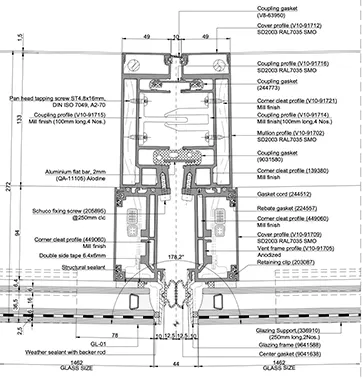

The façade used 1.5m x 3m panels for vision areas and 1.5m x 1m panels for spandrel areas. The composition of the IGUs used was: 6mm clear – fully tempered with 35% ferro white ceramic frit (#2) 2.5mm Kommerling interlayer 6mm FTO glass – heat strengthened 16mm argon cavity – 6mm Glastrosch Silverstar Combi Grey 40/22 t on clear (#5) – heat Strengthened.

The media glass laminate consisted of two glass lites, the rear pane of which is treated with a conductive, transparent coating to provide electrical conductivity. This surface is processed by robot-controlled lasers deleting the coating in such a way that only a fine transparent electrical circuit remains, onto which the corresponding LEDs are then placed and secured.

A second glass pane is then positioned on top of the LED pane at a distance of 2.5 mm. Finally, the space between the panes is filled with the special and exceptionally low viscosity LOCA material from H.B. Fuller I KÖMMERLING. This ensures that all integrated components are fully and safely encapsulated within the laminated glass. The LOCA element is then cured under UV-A light. The LED matrix embedded between the glass panes can be controlled to display media content and, depending on the LED type used, the image produced is either black and white or vibrant colour.

The View Hospital represents the latest large-scale building to embrace the sophisticated ‘4th’ generation of Media Façade technology which is taking hold around the world, enabling building designers and owners to not only enhance the visual impact of their structures but also tap into new revenue streams and ways of creating must-visit destinations.

A detailed look at the benefits of media façades shows how they enable buildings to tell their stories and interact with their environment. It’s not just about playing advertising content or simplistic light shows; now passers-by can play video games on the side of a building, façades can display real-time smart city data, host immersive events, display live art and music performances, show international sports games, play the latest Movie blockbusters, or in the case of an emergency, quickly display life-saving messages to the public at a giant scale.

The principal difference between older generations and the 4th generation of Media Façade technology is that the all-important LED electronics of the system are now neatly integrated inside the glazing units. This significantly increases the level of daylight transmission and visual clarity achieved, measured at 99% transparency. Previous generations saw the LEDs held in position with cable meshes and black plastic frameworks which were attached to the external surface of a façade. Not only is this approach unsightly, but it’s also cumbersome to install, with multiple potential failure points and high maintenance costs.

Now we have the new 4th generation, the LEDs are safely embedded inside a laminated layer within the glazing unit, and the electronics are neatly concealed within the mullions and accessible from the inside of the building. It also means that these LED glass units can be treated much like traditional glazing units and can be easily integrated into standard fixing systems. All of these improvements combined make for a much quicker and cleaner install, with no compromise on the Architects’ aesthetic criteria, delivering a far more durable and serviceable system.

There are further advantages to this new approach of embedding the LEDs inside the glazing unit. It allows for much greater flexibility to create glazing units that can meet certain performance targets, as additional glass technologies can be easily integrated into the build-up of the units. This also makes it straightforward to match a desired aesthetic from the design consultant. In the scenario where only a portion of a façade needs to have LED enablement, this new approach enables the LED glass units to be a perfect visual match for the rest of the façade when the LEDs are not in operation.

A current example of this flexibility can be seen in The View Hospital project which used a complex build-up of various glass technologies to not only provide the LED functionality but also meet stringent thermal performance targets and included a decorative screen-printed frit to match the rest of the façade which was not LED enabled. This was a true test of the flexibility of this new product type and proved unequivocally that this new generation of Media Façade technology can do things that would be impossible with older generations of the technology.

The View Hospital media façade was designed and supplied by GLAAM, a South Korean manufacturer who has been spearheading this new product category, integrating LEDs into glass laminate, since 2013. There is a continual cycle of development in the technology at their dedicated manufacturing facility in Seoul, striving to achieve ever-improved image quality and increased power efficiency to meet the evolving needs of the market. The international design community is exploring more and more what could be achieved with this new technology and continually feeding back to the manufacturer. GLAAM is now responsible for over 400 installations of this product type around the world and has built up a wealth of experience and technical insight in this quickly evolving niche.

This 4th generation LED glass product type is not limited to just building façades though, it can also be used for features in the public realm, roof canopies, temporary structures for events, and even flooring and geometric 3D structures. Effectively, any surface that uses glass, can now use an LED glass product to play dynamic media content and create a memorable and interactive environment.

This functionality ties in well with wider developments we are seeing in the retail, marketing, and experience industries with an ever-accelerating push towards interactive physical spaces that deliver fully immersive experiences, creating memorable and Instagrammable destinations. It seems that the holy grail of many creatives and commercial teams is to deliver unmissable wow moments that that can be captured on mobile devices and shared virally on social media. To achieve that, these creative teams are increasingly turning to LED displays combined with various other technologies and environmental sensors, which can trigger changes in the content, to deliver these memorable moments. Colours can change as you get closer to the screen, tight beams of audio can be delivered to individual people depending on what part of the screen they are looking at, and many other futuristic concepts are continually being trialled. LED glass enables these experiences to be located all over the building, increasing the creative team’s reach, and utilising physical spaces and surfaces that were previously untouchable. It’s truly an exciting usage of this innovative façade and glass technology, which combined with other experiential ideas, is set to deliver some fascinating Façade projects over the next 10 years.

Fast Facts

• Architect (Design): Chapman Taylor

• Main Contractor: UrbaCon Trading and Contracting (UCC)

• Electrical design company: ESC Lighting Ltd

• Façade Contractor: Profession Aluminium Company (PAC)

• Client: Estithmar Holdings / Elegancia Healthcare

Leo Mcdowall-Benton, G-SMATT Europe

Business Development Director

Leo McDowall-Benton is the Business Development Director at G-SMATT Europe. A graduate of Architecture & Planning, Leo has spent the last 15 years building and scaling businesses, operating at the intersection of architecture, construction, technology, and media. His role at G-SMATT Europe focuses on developing high-level relationships and multi-million GBP projects that benefit from market-leading transparent LED display technologies. This involves detailed work on go-to-market strategy, corporate partnerships, account management, and all aspects of marketing, prospecting, and sales process development.