The architectural hardware industry is gradually witnessing a new wind of change globally with the presence of several international and domestic hardware products in the market. The use of the latest technologies with different materials and finishes has increased extensively providing better quality, functionality, security, installation, look, etc. In terms of design, there has been a drastic evolution with a focus on a more minimalist and energy-efficient approach.

However, challenges abound in the hardware architecture product market. The market is pervaded with fierce competition coupled with a lack of information/awareness on prices, authenticity, test, standardisation, etc., which are still few and far between. Given the huge opportunities present within the challenges, the market is relatively buoyant and positive based on the demand from the growing housing and construction industry. The demand compels us to unleash more enhanced new products, and constantly innovate and upgrade the existing products, which gestures a bright prospect for the hardware industry in the country.

In an effort to grasp a clearer picture of the current scenario in the architectural hardware industry, we approached various experts and specialists who have been in the industry for considerable years equipped with in-depth knowledge of the industry and the products. They provide a comprehensive analysis of many aspects of the industry, such as technological advancement in hardware products, various test procedures for deciding quality, safety parameters, issues impacting the industry, etc.

Criteria for Selection of Architectural Hardware for Fenestrations

The world we live in is a continuous innovation. Market demands have been evolving over the centuries. Architectural design is being judged in detail and sometimes, what you think is least important is the most important part – for example, the architectural hardware for fenestrations, which is distinguished both by the quality and performance of the products, points out Ayman A. Adeeb, Area Manager, Master Middle East.

Given the increasing demand for high-quality materials, there are a lot of factors that one needs to consider in choosing a good product. The key factors to consider are quality, performance, manoeuvrability, design, functionality and durability, adds Adeeb.

The selection of hardware has to be mainly driven by functionality, performance and design, agrees Stefano Celani, Regional Sales Manager, Middle East, SchlegelGiesse. The right hardware combined with the right profiles, glass and gaskets can grant the end user a perfect solution, he adds.

Another criterion for customer selection of hardware is the finishing and the colour of the hardware and profile. Trendy finishing with special effects is more and more requested to customize each and every solution, adds Celani.

To look at the role of architectural hardware in façades, notes George Philip, DVP Strategic Projects, Middle East, Dormakaba, we need to see the bigger picture first, on what is the role of façades. Façades are not just playing a key role in architectural impact.

The building skin, as we sometimes call it, has functions ranging from protection from wind, sun, glare, fire and noise protection, safety and security, insulation, ventilation, energy gain, and even as a visual screen. Hardware that comes as a part of the building skin has to complement, and sometimes play a major role in the above.

There are lots of stakeholders in a project starting from clients, consultants, contractors and suppliers who influence the selection of architectural hardware in a project, observes Nassim Abu Yousef, Vice President – Middle East, Assa Abloy. A good mix of convenience and security with a focus on design and aesthetics should be the criteria for selection by decision-makers. He advises the customer to follow international performance standards suitable for local building codes in order to be sure that they are not compromising safety and security.

Agreeing with Yousef, Philip stresses the need for the right balance between security and safety. “Security is paramount, and hence hardware becomes critical, compared to any other part of the building,” says Philip. Talking about safety, strategic projects are particular on the need to have external doors which are a part of the escape route, which allow occupants to escape. “They predominantly have to ensure that the occupants have a free mode to escape, and in such moments, every second matters. Failure is not an option. Yet, during non-emergency times, such doors with their hardware have to be highly secure to prevent anyone from encroaching in,” he adds.

Talking about fire protection, Philip mentions that the hardware with the door as an assembly needs to ensure that the fire does not spread to the external surroundings, especially other walls, which are very nearby. When it comes to sound insulation, proper seals have to be in place to insulate the interiors from external sound. These seals take multiple roles, for sound and air filtration, he explains.

Criteria for the Selection of Rubber Profiles:

According to Urfi Kidwai, Managing Director, Gulf Rubber Industries LLC, the following are the criteria for the selection of rubber profiles:

• The selection criteria of the rubber profile depend upon the function it is to be used for – whether static purpose or dynamic. If the criterion is for the dynamic purpose, then physical properties like compression, and tensile strength with higher specifications would be required. If it is for a static purpose, then the lower specification is recommended. Accordingly, the standards are fixed, for dynamic conditions ASTM C-864 and for static conditions, the DIN7863 standard is used.

• The criteria for the selection of profiles depend on the scenario when the profile is in direct contact with silicone sealant and the temperature ranges from -20 to +40 degrees C. In both such weather conditions, we have to use silicon gaskets. In the other normal scenario, Ethylene Propylene Diene Monomer (EPDM) profiles can be used.

Fenestration Hardware: Latest Technologies & Trends

For centuries, the market had always been overwhelmed by the products being launched to consumers due to the evolving market for windows and doors, points out Adeeb and Philip. Celani of SchlegelGiesse observes that the latest technology in hardware is related mainly to aesthetic evolution (minimal trend) and technical performance (i.e., fire-rated solution). The minimal trend required more glass and a very small profile, so the hardware needs to be concealed or minimised to be incorporated into the whole system. Hardware with special material (AISI 316) having high corrosion resistance is also in demand. On top of this, the strict new regulations issued by the UAE Civil Defence for fire protection will drive the market (then hardware) to fire-rated products with specific certifications.

One of the latest in technology is electronic hardware, avers Philip, where the cloud is playing a major role. Instead of buying access control, which entails capital investment, the service can be rented out, in what we call ‘ACaas ‘ (Access Control as a service) where the client rents the service, and thus the outflow is smaller per month. They also get upgrades as technology is frequently being upgraded.

“We are also constantly beefing up our security to defend against cyber-attacks. This is no longer an option, but a necessity. Vandalism is also an issue. External hardware, and in particular, cylinders, have got several grades, for resistance against violent attacks and picking. They also need to withstand corrosion resistance, which is sometimes extreme in the Middle East,” adds Philip.

Technology is a double-edged sword, observes Philip. When 3-D printing machines came, we all got excited that objects could be made within reasonable budgets and minimum expertise. Yet, it is disrupting the keying industry, as any key can be duplicated in these machines! “Now manufacturers like Dormakaba, have come up with keys that have moving elements inside the key, preventing duplication on a 3-D machine,” he adds.

Talking about the hardware for doors, Yousef notes that the traditional door closers have evolved from rack & pinion to cam action/cam-motion® technology which also helps in meeting the norms of the disability act across the globe. Low-energy electro-mechanical locks and electro-mechanical keys are bridges to the future trends of mobility.

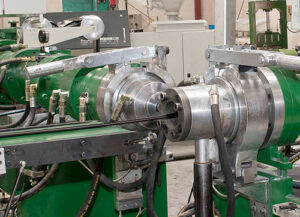

Considering profiles, according to Kidwai of Gulf Rubber Industries, sealing of co-extrusion profile is much better than single extrusion; hence co-extrusion profiles are preferably used for critical sealing for e.g., with sponge and solid. Co-extruded products combine two or more materials through a single die with two or more cavities arranged so that the extrusions merge and weld together into one structure.

Tests & Test Methods for Deciding the Quality of Hardware

Architectural hardware does not only focus on the functions of materials but also its durability, functionality and safety of the product, points out Adeeb. The materials will undergo various tests before being presented or launched in the market. Some of these tests are water penetration, air pressure difference, thermal break testing and safety guidelines. These tests are requirements for all hardware materials before being launched to ensure both quality and assurance to consumers of the products, and high-quality materials and to provide a comfortable home or office. These tests are also to set the international standard that is being offered to consumers and to develop a better solution to any possible instances that must be consistent with other program requirements. A balanced program with safety, security and performance measures a high-quality performance.

Shedding light on various tests, Yousef from ASSA ABLOY mentions that performance and fire tests like ANSI (American National Standards Institute), Builders Hardware Manufacturers Association (BHMA), UL 10C (Underwriters Laboratories), EN (European Norms) Standards, CE Marking (Conformité Européenefor European Economic Area) are some of the methods to know the quality and standards of any particular hardware. According to Philip, global standards are generally divided into either ANSI or EN.

There are subtle differences, but all of them serve the same purpose. In addition, as they are part of a façade, they need to undergo the same tests as a part of the façade assembly. Celani too agrees that CE and EN are the most common certifications. For some specific solutions the AAMA, an American Standard, is required.

According to Kidwai, there are two types of tests conducted – The in-house test to check the physical properties as per American Society for Testing and Materials (ASTM) – ASTM D-412, ASTM D-395, DIN-53504, DIN-53517 and British Standard BS-903 part 2 & part 6 to test tensile, hardness, elongation, compression and weather ability. Other mock-up tests, like the Thermal Cycling test, are conducted to see the gasket feasibility for the minimum and maximum temperature. Air pressure water penetration tests (ASTM E331-00) & (AAMA 501.1-05) are carried out at 1000 Pascals to test sealing, air filtration and water penetration.

Tests to Check air Infiltration and water penetration

The performance of building envelopes, windows and doors, related to air and water intrusion, is critical in maintaining the life cycle of a building and managing costs over time. Most, if not all, of the tests for air filtration and water penetration for hardware, are with the doors themselves, as it is a part of the entire door assembly. Hence the type of door, how snugly the hardware fits into the door construction, and the interface to the other elements of the building like flooring, accounts a lot for the final results of the tests.

There is a specific test done in accordance with European norms that rules the three main parameters – water tightness, air infiltration and wind pressure, points out Celani. On top of this, many companies want to have a sound reduction value. The target values (calculated in Pascal) change in relation to the type of opening (casement-sliding-cw).

Kidwai points out that the tests are conducted by the reputed test labs on the mock-ups of the structure to make sure there is no air infiltration and water penetration. “The design of the aluminium architectural system and the craftsmanship is perfect. In case of some penetration, we analyse the gap and identify whether to modify the sealing or alter the design of the gasket,” he adds. In case of any air infiltration or energy losses, design modification or customisation of the rubber profile will be done. An improved design of the rubber profile and selection of suitable rubber compounds will provide the desired results.

Penetration testing means the testing of a system to find its vulnerabilities (of the material). Air and water penetration testing determines whether the material is vulnerable to air and water resistance or effective. The security issue of the penetration tests may also have assessed potential impacts on the architectural hardware and suggested countermeasures to reduce the risk. The goal of these penetration tests depends on the type of approved activities for any given engagement with air and water. These tests are required for hardware materials to ensure the reliability of the product and its performance.

Standards & Certifications for Hardware

Standards for hardware detail the various tests that a particular product needs to undergo, to be given a particular grade. These tests range from durability, stress tests, cycle tests, corrosion tests, fire ratings, etc. Each of these parameters, when successfully passed, is shown in a classification code, observes Philip.

As an example, when comparing two similar-looking locks, customers should demand to see this classification, as this is the only way, they will be able to know the difference between two similar-looking locks. All things being equal, the one that has higher corrosion resistance, could be the product of choice for an external door lever handle or lock. Similarly, the choice would differ if it’s a product like a lever handle for a frequently used door like a toilet door (where cycle tests would be where I would give brownie points), adds Philip.

Celani says that the selection of hardware depends a lot on the application. For instance, if the window is installed in a traffic urban building- one of the main performances is the sound reduction calculated in DB (-40 DB has been already a good value). In this way, your room or house is isolated from the noise coming from outside. A seaside building must have hardware having a good rate of corrosion resistance due to the specific environment.

According to Yousef, EN Standards are more common in the region, but ANSI standards are also prominent in critical infrastructures like airports and hospitals. EN Standards are driven by European norms which are implemented throughout the European Union and acceptable in most of the countries across the globe. ANSI standards are driven by the American National Standards Institute which is based in the US and is used in the rest of the world as well.

Both ANSI and EN have similar tests, though there will be some variations. What is good is that on the websites of some certification firms like UL (in the USA) and Warrington (in the UK), one can see the certifications of the brands and products, enabling architects and clients to verify claims from suppliers, or even do comparisons on their own. This gives them the assurance that the products have got the certifications demanded in their project, explains Philip.

While looking for hardware used on windows and doors, one should consider an International Standard, suggests Adeeb. ISO Certification is the result of international organization standardization of technical work which are published as international standards.

IS0 9001:2015 provides an internationally tried and tested framework for taking a systematic approach to managing business processes to consistently turn products conforming to customers’ expectations. It consistently provides products and services that meet customer satisfaction.

It enhances customer satisfaction through the effective application of the system, improvement of the system and the assurance of conformity to customers and applicable statutory and regulatory requirements.

ISO 4001:2015 is an environmental management system that provides value for the environment, the organization itself and interested parties. The outcome of the environmental management system is the enhancement of environmental performance, fulfilment of compliance obligations and achievement of environmental objectives.

Many consumers, make sure to check the ISO Certification of the company they want to purchase materials from since this has become a requirement for companies worldwide to ensure international standards.

Rubber Profiles: Five Main Standards

• ASTM- C864, BS-4255 & DIN 7863 for EPDM rubber profiles

• ASTM-C1115 for Silicone rubber Profiles

• ASTM D-1056 for closed-cell EPDM profiles

The main difference between these standards is the physical properties of the rubber. For example, the tensile strength of rubber as per ASTM std is 12.4 Mpa, as per BS it is 10.5 Mpa, and as per DIN it is 7.5 Mpa. Likewise, all other specifications will be different for different standards. ASTM is of high specs and of the best quality among the three standards, then BS and DIN standard follows.

As told by Urfi Kidwai, Managing Director, Gulf Rubber Industries LLC

Selection of Hardware: Key Safety parameters

International standards for hardware should be considered while selecting hardware for any location and application, states Yousef. The hardware for any premises needs to adhere to stringent product configuration requirements. They need to be functional too.

When it comes to hardware for external building skins, security, weather resistance, sound and air filtration, amongst others are important, says Philip. In addition, as these doors are opened by everyone in the building, for convenience’s sake a master key is provided. But, where one key opens many doors, this convenience comes at the cost of security.

Losing such a key, compromises the security of the entire building, leading to costly replacements of the entire keying system! Hence, it’s important that a proper briefing is done with the facilities management team, to understand how the people flow is, for the building, before proposals are done.

There are a few more details. Talking about rubber profiles, Kidwai emphasizes a few key safety parameters: when we are bonding glass with aluminium, we make sure that our EPDM or silicone gasket is compatible with the silicone sealant. This needs to be checked by the silicon sealant supplier (as per ASTM C-1087). In the case of failure of bonding, there are chances of falling glass from the structure/building leading to damage to the structure or causing accidents and casualties. Fire door gaskets should also be fire resistant or retardant in order to safeguard from any accidents, mishaps or damage.

Safety parameters of architectural hardware, says Adeeb, cannot afford accidents and safety must be placed in its proper perspective. A correct safety balance cannot be achieved just by looking at the products, but also by the tests the products have been through. One needs to make sure that the material is reliable and consistent. One would need to consider the design and architecture, reliability, support systems, hardware specifications, product development, testing and maintenance of the product. Due to the International Standardization Organization, materials are being evaluated according to global standards. If the company is already ISO certified, it means that the products are already evaluated and is proven to be of international standard. It has already passed the safety parameters needed to make homes comfortable, safe and secure.

Innovations in Architectural Hardware

Yousef from ASSA ABLOY states that architectural hardware is moving rapidly towards innovative solutions like electro-mechanical cylinders, digital door locks, intelligent key cabinets, etc.

E-commerce has penetrated our daily lives and Architectural hardware is already getting the benefits by being part of this digital revolution. Most of the DIY solutions are being sold through e-commerce and in the next decade with the help of new technology like BIM; commercial solutions will be also part of this platform.

Philip from Dormakaba talks about mechanical innovations like features to prevent copying by 3D machines or some new functions in locks for better safety. Electronic innovations like Linear drive for sliding doors and revolving doors are also quite interesting. Certain products like Dormakaba’s TouchGo, which helps Alzheimer patients to identify and open their room doors is another breakthrough. The new technology – FOB on their lanyard, helps to transmit an RCID micro signal through their body to the lever handle, enabling only their door to open when touched.

Also, with the software technology, your face, your iris or your thumb becomes your key to open doors. Mobiles are also becoming a means to open doors. All of these make the physical keys irrelevant.

This trend has started, but it will take a long time to accept these changes. Then there are innovations that support the construction industry to collaborate and be more efficient, like BIM (Building Information Modelling). It is clear that manufacturers need to constantly invest in technology, to stay relevant.

Kidwai from Gulf Rubber Industries LLC has found EPDM gaskets as an innovative product for better sealing purposes. Two decades back, most of the aluminium fabricators were using PVC gaskets that do not have good weather ability as it is neither Ozone resistant nor UV resistant.

Also, the shrinkage was noticed at high temperatures, which indicated that there was a lack of sealing. He gives a list of multiple innovative products like silicone gaskets, co-extruded gaskets, vulcanized frames, silicone/EPDM setting blocks, fire retardant gaskets and rubber moulded products.

Adeeb from MASTER Middle East too finds innovation as a moving process, which comes with a lot of challenges. There will always be hurdles in the early stage and or in a breakthrough. Witnessing the evolution of architectural hardware is overwhelming, but being part of it is much more than being proud, he adds.

If one looks at it, windows before were merely openings in a wall that is for ventilation and lighting. Today, architectural engineering for fenestrations introduced us to tilt & turn, lift & slide systems and much more.

These systems are evidence of our evolving innovations over decades and centuries of architectural hardware and it does not stop there. It is still continually evolving, and it is the world to witness to what will architectural hardware to offer soon.

The Future of the Architectural Hardware Industry

The architectural hardware industry for façades and fenestrations is continuously evolving and the expectations of the consumers become higher, states Adeeb. The demands of the market depend upon innovations.

First, it was just a house, then a door to enter the house, followed by a window which is an opening in a wall with the primary function of ventilation and lighting. To provide consumers with their need and satisfaction, architectural hardware had upgraded its functionalities, and it is still continuously evolving.

According to Yousef, the future is digital and the industry has already adopted new technology like BIM and has already launched BIM-enabled software for consultants and architects. It’s designed to help users create complete, tailored solutions that add value throughout the building project lifecycle – from design and specification through to build and beyond.

Technology and several codes and standards with regard to safety and security play an inevitable role. “A welcome challenge manufacturers like us are facing is how service and form are getting to be the edge over others when product function is not a differentiator,” states Philip. He explains: a door closer is a mechanical product, and with most of the patents expiring, there is limited scope for differentiation in terms of function.

Hence its quality and after-sales service will be a key elements in the selection of the product, all other factors being equal. Automatic products like sliding doors and revolving doors, which are an indispensable part of every façade, traditionally have bulky motors, belts and pulleys.

Now, the entire mechanism is replaced with linear drive (similar to the magnetic levitation technology of Japanese trains) which is silent with few moving parts, and energy efficient.

In major international cities, the façade industry is strictly linked to aluminium curtain wall systems and high-rise buildings. Automation hardware, as well as concealed solution, is the most used in façade applications, states Celani. High-rise buildings required important test rates for wind pressure and water tightness due to the building height, he adds.

Agreeing with Philip, Kidwai too finds a manufacturer’s job is becoming more challenging day by day since the architects are coming up with extremely creative and complicated designs. “On the basis of the designs, we develop mock-up samples with different trial runs of the gasket, so it can pass air filtration and water penetration test.

For example, currently, we are doing an extremely prestigious project ‘Museum of the Future’, where approximately 9700 panels with different dimensions and specifications will be assembled. We have developed a silicone gasket to seal the panels for such a complex structure. We will foresee more complicated gasket designs in the future,” says Kidwai.

Hurdles Faced by the Industry

The architectural hardware industry is very old and is continuously evolving by adapting to the latest trends and technologies. Today, in a time of mobility, everyone is looking for security without compromising convenience, which is a challenge in itself. Higher security parameters bring less convenience and vice-versa. These days, of course, the market is very competitive and one solution doesn’t work for different markets. We need to be innovative and think out of the box all the time to satisfy customer needs and requirements, avers Yousef from ASSA ABLOY.

Philip observes that education, by far, is the biggest obstacle in the industry. There are several products that can solve challenges in the industry, but yet, the stakeholders are not aware of them, or short-term budget constraints take precedence resulting in quick-fix methods. Later, the client who takes over the building has to face the limitations. Retrofit, quite often, is then not possible or ends up being too expensive. Also, quite often, budget constraints force contractors to use products that could survive in the short term, but may not last for the period it was supposed to. By then, contractual obligations are over, and the operator/ facilities management has to take hard decisions – repair or replacement. Either of them needs deep pockets to fund such actions.

Kidwai too finds that the client’s budget constraints as the biggest obstacle. “When one thrives for excellence you are thrown up with lots of challenges starting from convincing the designer, technical manager, commercial aspects, and last but not the least the constraint of a budget. One has to be more competitive in order to achieve their expectations and requirements,” he adds.

Many internationally renowned fabricators and design managers come up with different ideas and they want to change the product also. “For example, now we are developing TPU setting blocks instead of EPDM. The reason being it is much better for cushioning effect and life expectancy is more. Another product we have developed is polyethylene profile as a stopper for silicone sealant which has excellent compatibility with silicone sealant,” Kidwai quotes from his experience. He finds the lack of a Research & Development department to do the feasibility check on the final product and its outcome as another challenge.

Adding to this, sourcing the required material, and setting up the apt process for manufacturing, in order to get the desired quality and competitive pricing is also challenging. Many find chasing the evolving markets’ demands and expectations as a major challenge. One needs to take the risk of developing unique quality materials, considering the competition and meeting the expectation of the consumers, observes Adeeb. Promoting a product is also a challenge because there are various things that one needs to consider, he comments. Hence, how the product is presented in the market and analysing the impact of the same is also important. However, it is always a battle between the company and its competitors.

Conclusion

The Hardware Industry has been growing steadily in the last decade. Hardware manufacturers have been engaged in developing technologies that improve the functionality of windows and doors, and they have come a long way. They have heavily invested in R&D to come up with hardware that is not only technically advanced but adds value to the looks of windows and doors.

Advancements in technologies have enabled improved designs and given precision to products with quality and sustenance. It is also moving towards digitization, automation, monitoring, remote access and management are the latest requirements driving innovation. With advancements in manufacturing technologies, more rigorous testing methods are followed to assure the quality of products. It is the vision of modern architecture that drives fenestration development and forces change! The future is bright and the focus needs to be on innovation and adaptation to the requirements of the customers, as also on sustainability and quality.