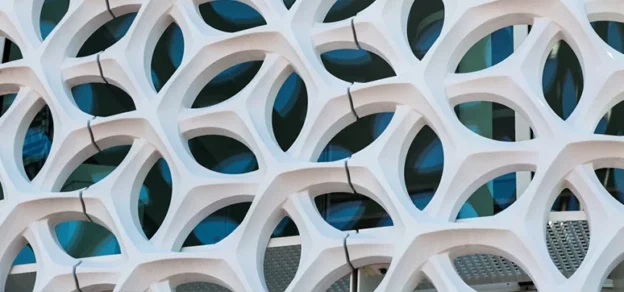

In the last 5 to 10 years, buildings had been adopting very innovative and interactive facades. The most recent technology of 3D printing will not only change the facades of the buildings but will also change the way buildings will be built in the future. Undoubtedly, the latest discussions in the construction industry anywhere is about the 3D printing of the buildings. Being a resident of UAE for last 20 years I feel very proud that Dubai is now leading in 3D printing technology. The largest 3D printed building in the world was built in Dubai which was unveiled recently in October 2019. Prior to that Dubai also built the world’s first 3D printed office which was inaugurated in May 2016. First, let’s talk about these two buildings in brief.

The World’s First 3D Printed Office – Office Of The Future

The “Office of the Future” was the first 3D-printed building of its kind. Though some other projects in the world had tested various elements of 3D printing before, this office was the first fully functional building to be built with all the services that people can use on a daily basis. A 3D printer measuring 6.0 metres high, 36.5 metres long and 12 metres wide was used to print the building. The printer consisted of an automated robotic arm to print the building. The entire structure was printed using a giant cement printer and then assembled on-site. Printing took 17 days and was installed in 2 days. Subsequent work on the building services, interiors, and landscape took approximately 3 months.

The labour involved in the printing process included 1 technician to monitor the function of the printer, a team of 7 people to install the building components on-site and a team of 10 specialists to take care of mechanical and electrical engineering. As a result, the labour cost was cut by more than 50% compared to the conventional buildings of similar size.

The World’s Largest 3D Printed Building

This two-story building of the Dubai Municipality is included in the Guinness Book of World Records as the largest 3D-printed structure in the world in volume. The building is 640 sq metres in area and 9.5 metres in height.

It has been built using a locally manufactured 3D printer and regular construction materials such as cement, gypsum, and sand with special adhesives. The foundation used both conventional and 3D printing methods, while the roof slabs were made of conventional construction materials. The walls are cast by the printer. The curves and different shapes of the building are printed quite accurately. It was built with 50 per cent less manpower and 60 per cent less construction waste. It meets the sustainability requirements and the green building standards.

How To 3D Print Buildings?

While the technology of BIM is already in place for designing buildings by the architects and preparing shop drawings by the contractors, the same can be extended and used for 3D printing of the buildings on site. Various components of the buildings can be 3D printed either on-site or off-site using special computer software fed to the printer. The process is quite simple e.g. with the use of a 3D printer, the walls of the buildings are cast in layers using a semi-fluid material along with their shapes and angles defined by a computer. The pump inside the printer pumps out the fluid and converts the computer model into the actual 3D building on site. The fluid material is infused with special minerals which instantly solidify the fluid material into the concrete.

Advantages And Disadvantages Of 3D Printed Buildings

It has been already proved that 3D-printed buildings are very cost-effective compared to conventionally constructed buildings. The waste generated by 3D-printed buildings is almost 60% less than that generated in the conventionally constructed buildings. 3D-printed buildings use much less labour than that required for conventionally constructed buildings. The pace of the construction using 3D printing is much faster than the conventional methods thereby accelerating the delivery times of the buildings. 3D printed buildings on-site use very few materials manufactured away from the site thereby reducing the transportation cost and saving the fuels and natural resources. Human errors are almost nil in the 3D-printed buildings.

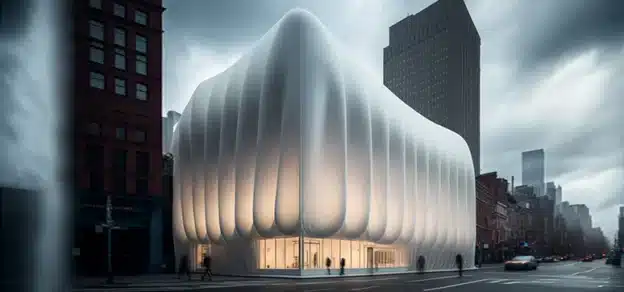

All these advantages of 3D printing can be used for constructing affordable housing. Affordable housing is the biggest challenge faced by many countries across the globe. The advantageous use of the technology can also be used in rapid prototyping and construction of repetitive designs such as gas stations, bus shelters, labour accommodations, district cooling plants, electrical substations, etc. Moreover, it will be a lot easier to construct the challenging shapes and forms of the building components using 3D printing technology. The 3D printer is small in size, light in weight and easy to transport from one site to another by a regular truck. Also, 3D printing does not require long preparation procedures prior to the commencement of the construction.

The only disadvantage of the 3D printed buildings which industry experts express is that they may not be flexible enough to meet the changing requirements of its occupants over the years. It would not be possible to modify the layouts as the walls are printed in concrete. Also currently, the printing process is not a very refined technology so it is difficult to create smooth and perfect surfaces with 3D-printed concrete. However, once the technology improves, it will be possible to print intricate designs with a high-quality finish. There is still a lot of research going on in developing the materials to be used for 3D printing, the methods of calculations to evaluate the structure and technology for horizontal construction such as slabs and roofs.

Dubai Leading The Role in 3D Printing

Dubai is known for its glamorous architecture and innovative engineering in the building industry. To continue the trend, the Dubai government and Municipality are working towards making Dubai a hub for 3D printing technology and becoming a leading global centre of 3D printing. They are setting rules and regulations for 3D-printed buildings. Dubai aims to construct 25 per cent of the future buildings using 3D printing by 2030. Plans are now in the pipeline for the world’s first 3D-printed skyscraper. Dubai is set to be a world leader in showcasing 3D printing construction techniques.