What are the criteria for the selection of architectural hardware for façades & fenestrations?

Hardware contributes to less than 1.5% of the value of the project, but is contributing to 95% of the problems when it is not installed correctly. In addition, a user who enters the building does not touch the walls, neither the ceilings nor the floors. The only element of the building he/she touches is the lever handles and the pull handles. I keep repeating this, because, these are items that are finalised in the finishing stages of the project when the budgets are finished, the main objective at that stage is to somehow fit something and close the doors. It is no surprise that within a couple of months, you see the hardware falling off.

Now that I have highlighted the concerns, let me focus on the selection. A good specifier will select hardware such that the user finds it intuitive when he approaches the door. A manual sliding door needs to have an offset pull handle, with a directional sign to slide to the side. A swing door needs to have a pull handle on the pull side and a push plate on the pull side. That is intuitiveness. Once this logic is clear, next comes the function. Some doors are locked from one side, and always free to exit from the other side. Others have sensors to open the door automatically to exit or enter.

For deciding the function, the use of the door is paramount question to ask and it is also important to know that how the user will use it. Once you have selected the function, next is conformance to the standards. Every piece of hardware that comes on the door, has a particular standard, which calls for several criteria to be ticked before its selected. For example, a door closer needs to pass almost 8 criteria-from durability (cycle test) to corrosion tests-before it can conform to the standards.

What are the latest technologies in hardware products?

I must say that the industry has not seen a lot of mechanical innovations, but there has been a lot of developments in the electronic front. Some of the mechanical innovations have been the classroom function that changed after the Colorado school shootings.

Earlier, under emergency conditions, the teacher had to go outside the door, put the key into the lock and lock the lever handle, to prevent anyone from entering the classroom, and then run back in, to shut the door. This action could jeopardise the teacher‘s life and the students she is trying to protect. Now the new classroom function has a feature such that when the teacher inserts the key from the inside of the room (avoiding going outside), the outside lever handle gets rigid and locked, preventing anyone from coming inside.

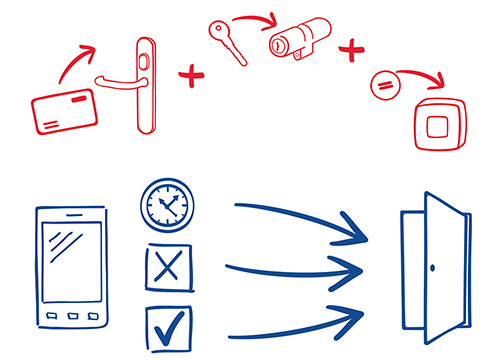

Advancement of hardware, is more on the software side, from connectivity to smart homes, to cloud based systems. The customer does not have to pay upfront the full amount of the locks and the system, but just pay the rental charges of the system. This has financial advantages, as there is no addition of assets, avoiding blocking of funds and reservation of depreciation every year. The customer also gets software updates immediately and hence uses the latest product advantages.

What are the key safety parameters to look for while selecting hardware?

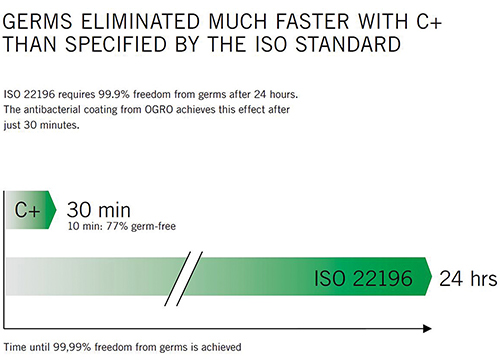

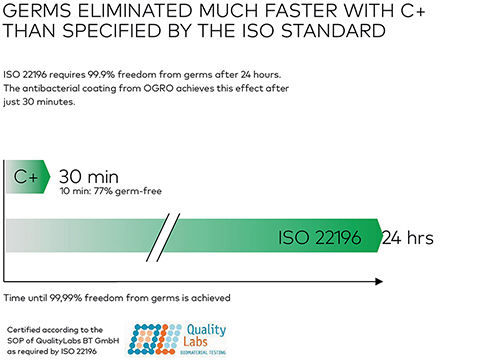

One of the basic steps to follow is to insist on certified products that meet the relevant standards. Also, while minimum standards are what is prescribed, try to go for the higher grades within the standards, as this will prolong the proper use of the door. In the meanwhile, many new criteria have come in. One of them is making the hardware suitable for people who are differently challenged. This will reflect on features like the door closing devices requiring a force of less than 5 lbs to open. Lever handles that do not have sharp edges, and a backbend return to prevent the lever handles from slipping when they are used. There is also an antibacterial coating to prevent germs from spreading.

What are the test methods for deciding the quality of the hardware used in windows and doors in the Middle East?

The Middle East region has corrosive weather conditions. This means that the hardware, especially the ones installed on exterior doors, needs to withstand corrosion. The hardware can be PVD coated to help resist deterioration due to weather conditions. The other common problem is the high wind conditions that are prevalent at some times of the year. This can be mitigated by using a product that has successfully passed high wind conditions. The examples which include closers that have high closing forces (without compromising on the maximum force to open the door) are a good fit in such a scenario.

Tell us about the future of the architectural hardware industry.

With the stagnation of innovations in architectural hardware, the focus of every company is to go towards electromechanical and software-dominant applications. People do not want to use keys, and the mobile becomes an all-encompassing tool to open doors. This brings in digital hardware, that can be opened remotely, and also by cell phones. Integration with smart devices in the home opens a lot of opportunities. Also with the cost of sensors dropping, everything on the door can be monitored, right from the cycles it has completed, to even the sagging of doors, etc.

So dream of the day that the doors can send signals back asking for maintenance, or predicting that the hinges need to be oiled. Still better is when you open the door, in the evening, coming back from work, and lever handles will sense your identity and send a voice message from your wife (who has gone shopping!) that the dinner is in the fridge! It is not just always about the functions. With 3D printing now common, users can, in future, design and print their lever handle designs and fix it by modular means to the door lock. Currently, even the functional door closer is trying to be an architect’s darling, by opening up possibilities of mixing and matching bodies and arms in different colours (like a Lego toy) to match other items on the door or room!

What are the challenges faced by the hardware industry in the Middle East?

The current challenge is the lack of quality projects due to the tough time the real estate is going through. This means fewer projects and more competition. Yet looking back, it is been a satisfying couple of decades, where Dormakaba raised the benchmark and created the market for quality hardware, and in the journey, created globally recognized applications. While new projects are limited, yet the huge amount of installed base, by itself, is a market that we have to service, backed up by one of the largest service teams in the region. Renovations are also on the rise, especially in the hospitality sector, which needs to innovate/ renovate every 10 years to be relevant to the customer.

What role automation is playing in the architectural hardware industry in the Middle East?

There is a major shift from mechanical hardware to electromechanical hardware. Connectivity has brought many changes to openings – right from remote access, monitoring, flexibility of giving or taking back access, etc. With the shared economy taking over and disrupting many businesses, right from hospitality to transportation, we have taken a leap and launched Access Control As A Service (AaaS). This means you don’t have to pay upfront for the equipment (no asset burden for the customer), but just pay a nominal rent for the equipment. This also helps us to update the software to the customer and keep him updated with the latest technology. We also provide other services like remotely changing access rights, etc., for those who do not want to be bothered about the operational aspects of the system.

What is the importance of fire safety aspects of the architectural hardware industry?

Every building has a primary function of protecting its occupants. As openings specialists, it translates into how openings can be designed to stop the fire from spreading into the building. These doors must help people to escape without any prior knowledge of the function of the door or the hardware on it. They should also intuitively guide people to use the right doors to escape and provide the signage of the door.

The occupants in the hospital may not be in a physical and mental condition to escape and hence should be able to stay safely in their rooms till rescue comes in. Thus here, in addition to fire, smoke plays a major role. People die of smoke than of fire. These doors then should have appropriate hardware like seals, to prevent smoke from infiltrating the openings. The architectural hardware and door suppliers, at the design stage, need to have key discussions with the architect and the fire consultant, before the right proposals can be specified.