In the past when the land was abundant and urbanisation was far less than what we have today, we built more horizontally, and not very tall. There were also restrictions to building tall when it came to construction and building technology available at that time.

With advancements today in construction and building technology, we learnt the science of building tall owing also to rapid urbanisation and lack of space in cities. However, such buildings were predominantly concrete structures with a higher wall-to-window ratio.

With advancements in glass & aluminium technology, we then began to see buildings getting enveloped by this new form, which also brought about a greener and quicker way to build tall, with vastly brilliant views compared to conventional concrete and window buildings.

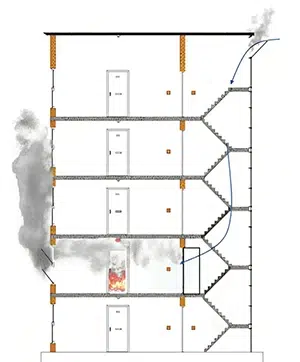

With that said, these types of buildings pose a higher risk when it comes to fire & life safety due to their sheer height, higher occupancy loads, a mixed bag of interior fit-outs and usually, not well-thought-out fire strategy behind its design.

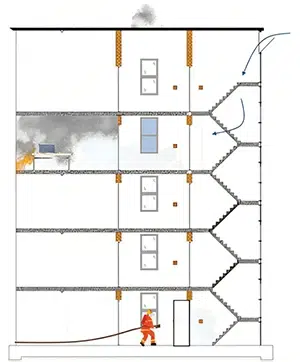

In our region, many buildings that are high-rise, above 15 meters and beyond, up to super tall scaling 200 meters and beyond, the facilities to ventilate smoke during a fire emergency are usually not given enough importance as much as it should be given. In older buildings, which are more concrete and windows with open-to-sky areas, smoke will not tend to collect as there are channels for it to pass through to the open air, and concrete buildings were also not clad with ACP in the earlier days, which is also a growing cause for concern in modern-day buildings, like leapfrog of fire, smoke from floor-to-floor, and secondary debris.

Modern Glass enveloped buildings are also accompanied by, in many or some cases, aluminium composite panels, which can cause a catastrophic combination when it comes to building fires today. In our region, there is little to no focus on having separate smoke shafts to extract smoke from the occupant areas, lift lobbies, and corridors to the building roof of glass façade buildings like in Europe or America. This is the reason we have in the present day, Top Hung Open Out Manual Vents which are presently fitted with handles. The providers of this system too are unaware as to why they are providing a window with a handle, and most think it is for Natural Ventilation, which is not the case.

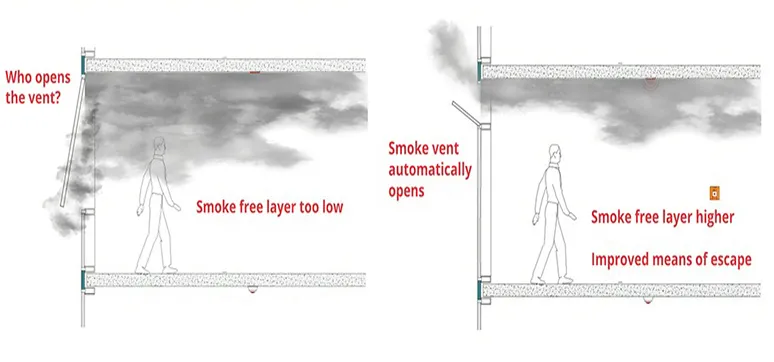

This is not the right way to place the vents, nor is it ideal or to be expected of an occupant or a fire officer to open the vents when there is a fire in the building. Also, as seen in the representation (Figure 4), the smoke will tend to settle at the person’s waist as the opening is kept at a low level. In many cases, the vents are also too large to be opened by an individual or are stuck due to lack of maintenance or handles removed, in highly data-secure properties. This is as good as not having any system for smoke extraction as it is manual, cumbersome to operate, and will not open easily due to lack of maintenance in most buildings.

Openable panels shall be provided on each floor and shall be spaced not more than 10m apart and measured along the external wall from centre-to-centre of the access openings (Figure 4). Such openings shall be operable at a height between 1.2 m and 1.5 m from the floor and shall be in the form of openable panels (fire access panels) of size not less than 1000mm X 1000 mm opening outwards. The wording – ‘FIRE OPENABLE PANEL – OPEN IN CASE OF FIRE, DO NOT OBSTRUCT ’of at least 25mm letter height shall be marked on the internal side.

Such panels shall not be limited to cubicle areas and shall be also located in common areas/corridors to facilitate access by the building occupants and the personnel for smoke exhaust in times of distress. With advancements in technology and in today’s world of Automation, we have systems that can automate the vent in the incipient stages of a fire in commercial glass façade buildings, related to occupant areas, lift lobbies, end of corridors, stair top, and in Public Buildings using Make-up Air vents on the vertical Façade and Smoke Vents or Hatches on the roof, based on Stack- Effect Principles. Products must be tested and certified to EN12101’s respective clauses and annexes.

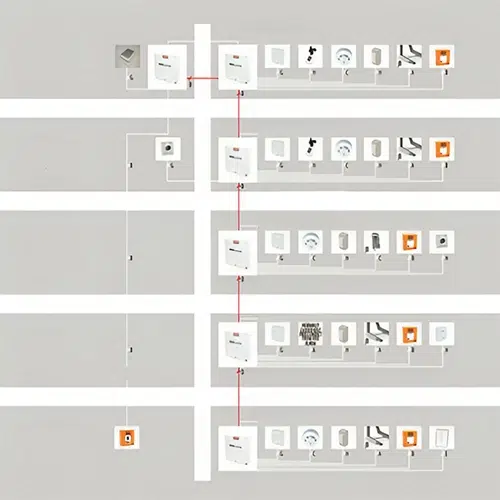

For Commercial Glass Façade Buildings,

- The automatic Vents which are in Occupant Areas, are to be of Bottom Hung Open Out placed as close to the false ceiling as possible, as that would be the smoke extraction zone. This can be made applicable in Schools as well.

- The automatic Vents in Lift Lobbies and the End of the Corridor can be of the same Bottom Hung Open Out, or a square-shaped Side Hung Open Out, this can be made applicable in Hotels, Schools, and Hospitals as well.

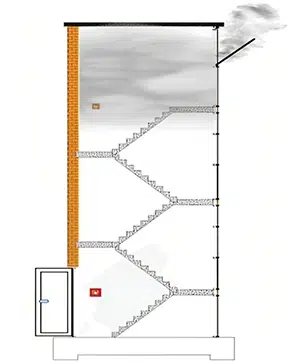

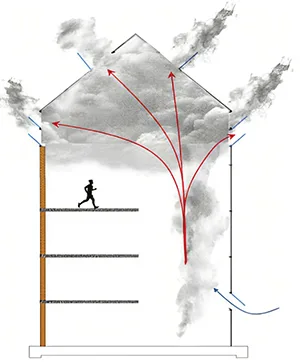

- In Escape Stair locations, where pressurization or no means of Smoke Ventilation is provided, we must provide Bottom open vents at the top of the stair vent, and this will act as a stack effect. This can be made applicable in hotels, schools, and hospitals as well.

Large Public Building spaces like Malls, Airports, and Railway Stations

these buildings are designed with large open spaces, with double and triple-height sections. For such locations,

- We need to provide Make-up Air Ventilation on the vertical façade using, low-level Top Hung Open Out Vents (these can be on the areas of the glass façade covering the building with designed Effective Free Areas kept in mind, including entrance canopy areas can be used)

- Combined with Roof smoke extraction units or High-level Façade Vents Bottom Hung Open Out which will automatically open for the smoke to release from the roof area, this is when the building does not have mechanical smoke extraction.

In both the cases explained above, the following are to be taken care of when calculating the sizes, and amount of openings, and as this system is related to Fire Safety, care is also to be taken when considering cable type, sizing, and distances,

-

Figure – 8 Atria ventilation with make-up air ventilation & roof or top of façade automatic extractors The size of the vent to be shorter and wider, than taller, this will give more angle of opening.

- No. of Vents to be calculated based on 2.5% of Floor Area for Commercial Buildings, and 3-3.5% for larger public utility buildings.

- For the Free Areas, we can only use the area of Effective Smoke Release and not Punch Window.

- Cables are to be of Fire Survival or Fire Rated Low Smoke Copper Armoured with cable trays if required (this will be based on MEP/Fire Specifications)

- The diameter of the cables is to be chosen based on the distance of AoV from its respective control panel, to avoid Voltage Drop issues.

- A proper maintenance schedule and AMCs must be kept in place for the system to function as designed when called for during an emergency.

Above are only some of the considerations, among others like Actuator selection, Controller Configuration, Schematics and Weather performance, to be made when designing an Automatic Smoke Ventilation System (ASVS) for any building type. Contact us to specify the right.

Considering the varied applications as seen in this article, the cost of implementation being more optimal than Mechanical Extraction, including its Maintenance, when done right, combined with the ongoing trend of Glass Façade Buildings, we see Automatic Opening Vents (AoVs) as the way to go with Future of Fire & Life Safety for early Smoke Extraction for all Glass Façade building types in our Region.