The exterior finish layer known as cladding is put in place to cover support structures and/or exterior walls. This finish layer has various advantages, including aesthetic enhancement, improved thermal and environmental performance, and protection from unfavourable outside factors. Numerous cladding system choices are currently offered on the market to make improvements in building technology and building materials.

There is a wide variety of materials, and each has advantages and disadvantages. Your choice of building cladding depends on a wide range of elements, including the building’s size, construction, function, budget, and location. But safety must come first and foremost.

This cover story presents the views and opinions of subject-matter specialists on the topic of cladding. We asked them a few questions about their preferred cladding materials, norms and regulations, cladding for green buildings, and other topics.

Trends in Exterior Wall Cladding

Kaman Wong, Senior Façade Engineer (UK), AESG says, in the old days, external walls mainly provided weather protection to the people. But nowadays, we are expecting more and more for building envelopes like thermal comfort, ventilation, daylight… you name it! “With the impact of global warming, I would say one of the major trends is to have more sustainable cladding during the building life cycle” she adds.

The industry has been looking for exterior wall designs to reduce carbon emissions during construction and operation. The other major trend would be BIM implementation in envelope design, although BIM has been implemented for a while in the UK, most of the industrial surveys and academic research still show the uptake of BIM is slow, particularly for cladding specialists and supply chains.

According to Parasuraman Sridharan, Project Manager (Fujseng Construction LLC), the cladding industry has witnessed a spate of developments in recent times, viz., from basic rainscreen pressure equalised systems to present-day kinetic façades, double skin façades, closed cavity façades, Building Integrated Photovoltaics, green façades, free-form cold bending façades, fire-protection assemblies, etc. to name a few.

Such advancements are engineered to improve the cladding envelope’s aesthetic appearance, durability, and performance of the building by reducing the consumption of energy, water, and material, finally leading to enhanced public health, safety, and general welfare so as to meet the highest standards of sustainable development and pollution-free environment.

Somayah Rajab, Senior Architect (Egypt), Dewan Architects & Engineers believes that the current trends in wall cladding include metal composite panels, aluminum composite panels, polycarbonate panels, EIFS, ETICS, GRC, GRFC, GRP, glazing, insulation, sealants, etc.

Most Preferable Cladding Material

“I think no single cladding material can satisfy all the performance criteria. When selecting one material, there is a compromise for all performance parameters. For instance, aluminium has been popular material because of its lightweight”, says Kaman. Cost economic and easy fabrication, however, it generally does not give good impact resistance. Traditional handset Bricks have been a favourite for some clients, but it generally takes longer to construct so it is not suitable when you have tight programmes. There are a lot of other cladding materials, such as timber panels (HPL) which are more environmental friendly but it creates fire safety issue and would not be suitable for high risk buildings.

Parasuraman adds that a well-designed and properly installed cladding offers added durability, improved performance, minimises fire propagation and provides protection & good thermal comfort by minimised air leakage & better control of internal temperatures with lower capital, running cost and low maintenance cost. As a result of its physical properties, flexural strength, and durability & flexibility & wide range of finishes, aluminium is considered one of the most versatile materials in not just building wall cladding but also in the aerospace industry as well.

The aluminium alloy 6063 is sufficient for anodising as other alloys are harder or softer and hence this alloy is most commonly used in the curtain wall & cladding industry. Parasuraman specifies it in below points:

- Specific weight of aluminium -26.6 kN/m3

- Thermal co-efficient of aluminium alloys – 23 *10-6 m/m°C

- Melting point – 550 to 650°C

- Modulus of Elasticity – Ea= 70000 N/mm

- Physical properties refer to BS 8118-page 22 & BS1474.

Somayah prefers EFTE cladding for its friendly environmental solar screening and characteristics.

The Common Cladding Materials & its Key Characteristics

1. Terracotta (Also known as “baked earth” in Italian): The clay is fired at extremely high temperatures and thus makes it a natural fireproof material. This material has strong resistance to bacteria and algae and we find its usage in ancient Indian & Chinese temple roofs and prestigious buildings.

2. Glass (Non-structural external wall cladding): This approach of cladding is most preferred for multi-story buildings and the advantages are the aesthetic, acoustic, thermal and flexural strength. Usually, aluminium alloy 6063 is used as a structural joint in the curtain wall industry.

3. Tile /Ceramic (Artificial): Ceramic Cladding is highly weather-resistant, UV -resistant, non-combustible, impact-resistant, and low-maintenance material which is produced in a sustainable approach and is 100% recyclable. It is anticipated to grow exponentially in the future.

3. Tile /Ceramic (Artificial): Ceramic Cladding is highly weather-resistant, UV -resistant, non-combustible, impact-resistant, and low-maintenance material which is produced in a sustainable approach and is 100% recyclable. It is anticipated to grow exponentially in the future.

4. Metal (Paradigmatic metal is Aluminium Composite Panels (ACP): Aluminium has beneficial properties such as lightweight, recyclability, resistance to fungi & algae, and easy installation. These panels are widely utilised for sound & thermal insulation, fire resistance, and improving the aesthetic appeal of buildings. Aluminium alloy 3000 series is generally used as outer skins of ACP material.

5. Stone (Natural from mother earth): Stone veneers found naturally from the earth i.e. Granite, slate, marble, limestone, travertine, sandstorm, etc. are similar to ceramic tile material in most cases except for the fact that the natural stone is more durable and requires low maintenance. A point to note is that natural stones are quite expensive compared to ceramic tile cladding.

6. Perforated Mesh (Ventilation /solar shading & privacy barrier): With the current trend towards building sustainable homes with a minimum impact on the environment, this ancient perforated façade cladding system is re-gaining popularity as they are instrumental in maintaining thermal comfort and allowing the designed day light & sound, thereby significantly reducing energy consumption. In general, aluminium alloy 5000 series is preferable as its high corrosion-resistant and avoids fracture properties in perforated mesh screens.

– Parasuraman Sridharan, Project Manager, Fujseng Construction LLC

Role of Cladding in Constructing Sustainable Buildings

Kaman notes, an external wall normally represents 15 to 40% of the total construction cost which you can see that it can account for more than one-third of the construction budget! Besides, the drive for low-carbon emission buildings will put increasing focus on the embodied and operational carbon in construction. Many case studies and research show that a passive design approach and optimised building strategy is shown to significantly reduce operational carbon. For example, optimising façade design by sustainable glazing rations, u-value, ventilation, and shading measures.

Kaman notes, an external wall normally represents 15 to 40% of the total construction cost which you can see that it can account for more than one-third of the construction budget! Besides, the drive for low-carbon emission buildings will put increasing focus on the embodied and operational carbon in construction. Many case studies and research show that a passive design approach and optimised building strategy is shown to significantly reduce operational carbon. For example, optimising façade design by sustainable glazing rations, u-value, ventilation, and shading measures.

In Parasuraman’s view, with all façade materials that are recyclable, reusable, non-toxic, and chemically inert, one can be assured of sustainable construction that doesn’t harm the environment. Sustainable buildings are those buildings that are highly energy efficient in terms of the usage of energy, water, and recyclable & renewable materials with reduced impacts on the health and the environment.

• The glass cladding material is generally manufactured with appropriate width & cuts to sheets at the factory, reducing or eliminating field cuts and waste at the site. Wooden Pallets are used for packaging and can be recycled easily and are bio-degradable.

• The Aluminium Composite Panel material i.e. the outer skins of aluminium sheet and the core material are completely recycled easily and bio-degradable.

• The offcuts of ACP generated at the job site & offcuts of glass in the factory are completely recyclable without any residue.

• The protective layer of Polyethylene Plastic is 100% recyclable.

• Cladding Life cycle Assessment along with main raw material supplier LCA supports having a longer life for the buildings.

• Cladding being mechanically attached to the building makes it easy to remove at any point.

• ACP & Glass materials are low VOC (Volatile Organic Compound) emitting materials and the associated sealant material is approved under the slab of regulations which stands evident towards an environment-friendly approach.

• Material Composition changes are not anticipated during its life and no waste is generated during use making it a longer sustainable choice of building cladding.

Cladding is very important in any building envelope. It provides insulation, façade cleaning, durability, and maintenance as well as aesthetics to the building, says, Somayah.

Role of Cladding Technologies & Materials in Regulating Daylight & Ventilation

Kaman believes that one of the benefits of cladding is to provide openings for daylight and ventilation. Daylight normally is achieved by window or door openings, and how are they dimensioned and positioned in the exterior walls considering climate conditions and adjacent buildings? She adds cladding can also control the heat exchange between the inside and outside environment.

Kaman believes that one of the benefits of cladding is to provide openings for daylight and ventilation. Daylight normally is achieved by window or door openings, and how are they dimensioned and positioned in the exterior walls considering climate conditions and adjacent buildings? She adds cladding can also control the heat exchange between the inside and outside environment.

In summer, the building is usually cool at the start of the day, during the day, machines and people generate heat and the sun would also shine. The heat is then absorbed by the fabric of the building. If the cladding consists of an element that has a high heat capacity such as concrete, the temperature inside increases but not significantly. In the evening, the temperature would drop outside, and the internal heat restored can be vented through openings to achieve passive cooling.

Parasuraman adds, according to a new study in the Solar Energy and Building Physics Laboratory at the Swiss Federal Institute of Technology in Lausanne, Switzerland, people who spend more time in natural lighting than in artificial lighting have increased productivity and alertness. Light directly influences the amount of melatonin a person produces, which indirectly affects alertness. Most people spend their days within buildings under different lighting environments, which range from daylight to artificial light. Today, the regulation of daylight and ventilation is computed using various tools like fenestration shading analysis, daylight shading analysis, heat gain analysis, sun path analysis, and energy analysis.

The depth of the sun breaker or say bullnose attached to the façade has a reasonable impact on the daylight shading. Ideally, a 400mm deep aluminium extrusion fin attachment provides a value of 0.31 which is an ideal comfort in shading analysis. As we witness the advancements in home automation, sun breakers are aligning with AI integrated into our phones and environment i.e. based on the position of the sun /clouds the breakers would be available to tilt at different angles for better performance from the sunlight along with curtain blind from internal side helps regulation of the required daylight. Al-Bahar tower is one of the famous buildings in Abu Dhabi which has won the 2012 Tall building innovation award due to its brilliant climate-responsive dynamic façade.

Intelligent & Responsible Cladding

Kaman’s definition of intelligent and responsible cladding is that cladding is adaptive to the changing external and internal conditions, whilst maintaining comfort to the occupiers. It can repeatedly and reversibly modify its functions for those changing conditions. Like a shading device changes its angle depending on the direction of the sun. Cladding system to monitor heat exchange as mentioned above.

Kaman’s definition of intelligent and responsible cladding is that cladding is adaptive to the changing external and internal conditions, whilst maintaining comfort to the occupiers. It can repeatedly and reversibly modify its functions for those changing conditions. Like a shading device changes its angle depending on the direction of the sun. Cladding system to monitor heat exchange as mentioned above.

Parasuraman observes that the CCF –Closed Cavity Façade is emerging as the most intelligent advancement replacing the double skin façades wherein the inner façade is triple-glazed and the outer is single-glazed. This enables the dry air to be dispensed into the cavity which prevents condensation formation, while the dry air is monitored electronically and is adjusted per the required comfort level. The CCF integrated with BIPV sun-breakers would be one of the intelligent and responsible cladding. The low cost of cleaning CCF is an obvious advantage over double-skin façades.

“I think now developing technologies look to allow building skin to interact between external and internal environment”, says Somayah.

Smart Cladding Solutions & Technologies

Below are the listed solutions and technologies by Kaman:

• 3D printing technology for manufacturing has been popular. VULCAN is the world’s largest 3D printed building made in Beijing, they are made from more than 1000 units, and divided into several identical modules, allowing them to fit.

• Point cloud surveys, have been quite common when doing dimensional surveys for existing building structures. The accuracy tolerances can be down to +/- 2mm. The data can be used to produce 2D or 3D documentation.

• Digital twins. This is a digital replica of a living or non-living physical entity. This is usually achieved by putting sensors to measure real-time data whilst this data would be used for planning energy use or monitoring building performance.

Somayah sees the solar panel façades cladding and the ventilated façades as an intervention for efficient energy upgrade of new and, mainly, existing buildings. It focuses on the requirements that this specific building element should fulfil regarding legal, technical, social, and financial aspects.

Role of Ensuring Safety and Security through Cladding, Testing & Certification

According to Kaman, one of the primary functions of an external wall is to provide protection for occupants from the external environment. Cladding requires to be strong enough to resist loads, e.g. wind, snow, maintenance and impact loads. This can be normally achieved by having metal subframe support which will transfer the loadings back to the primary structure. It also requires providing burglar and impact resistance for high risks areas to provide security and avoid frequent maintenance due to vandalism. There are several test standards for assessing cladding performance such as CWCT testing which determines the level of serviceability of a façade system when subject to weather conditions and solid object impact.

Norms & Standards for Façade & Cladding in Building Envelopes in Your Region

Kaman highlights the norms & standards in the UK below:

• Approved documents A to Q and 7 provide statutory guidance for external wall design.

• The other standards are CWCT technical notes and their design guidance such as CWCT – Standard for Systemised building envelopes.

• CWCT has also published some sustainability guidance on cladding design where over 60 individuals from over 30 companies were actively involved.

Somayah says, if we deal with the building as a thermal system, the correct choice of its parts and their relationships can be composed utilising a frameworks approach. This can be accomplished by integrating an improvement method into the thermal performance of the building right on time in the outline procedure. This requires designing the building all around as a thermal system in an appropriate structure for the different methodologies.

The goal is to assess the potential of façade cladding to save energy by studying its thermal performance and summarise the outcome of a simulation analysis to determine the inefficiency of envelope construction cladding in reducing energy consumption for buildings in Egypt.

Performance Mock-up test

1. Air Infiltration / Air Exfiltration – ASTM E 283

2. Water Penetration test under Static Pressure – ASTM E331

3. Water Penetration under Dynamic Loading – AAMA 501.1

4. Structural Wind loading – ASTM E 330

5. Thermal Performance – AAMA 501.5, ASTM 1503, ASTM E 1423, NFRC 500

6. Seismic movement – AAMA 501.4

7. Fire Certification – ASTM E 84; ASTM D 1929, EN -13501-1, ASTM NFPA 285

Field Testing

1. On-site air infiltration – ASTM E 783

2. On-site Hose test – AAMA 501.2

3. On-site Static Water test – ASTM E 1105

4. Sealant Adhesion – ASTM C 794 / ASTM C 1135

5. Acoustic Testing – ASTM E966 / ASTM E 1332

Cladding Materials for Future Façades Cladding Materials for Future Façades

“I feel cladding systems in the future should be a low environmental impact, and they should have a low thermal conductivity. It also needs to be compatible with the different shapes of forms of construction and it should be suitable for modern construction methods such as casting to precast panels”, says Kaman. Parasurman observes that the current energy crisis in Europe and the inflation of fuel prices around the globe is an eye-opener, and trust the region will implement more BIPV building Projects with better energy compliance standards.

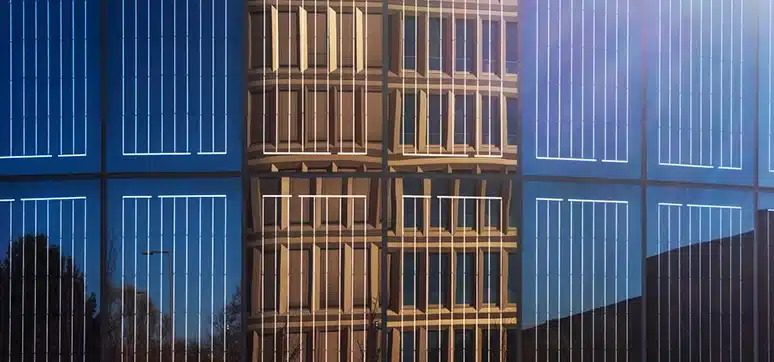

Building-integrated photovoltaics (BIPVs) are products with crystalline silicon modules that are integrated parts of the building envelope. The adaptation of solar technology into the building envelope is smart cladding moving us forward toward better energy policies. Crystalline silicone laminated cells are placed in between two lines of tempered/heat-treated glass, spacing them depending on the amount of light transmission required by the project (0% to 50% approx.). The spacing between the cells is fully customisable, achieving efficiencies of up to 18%. The technological development of building-integrated photovoltaics with a variety of glass forms, colours, and optical structures of cells, glass, and profiles enables creativity and a modern approach to architectural design.

This allows us to become more sophisticated with window, façade, and curtain wall solutions that are active, smart, and energy-generating. Somayah sees interactive façades with solar radiation as the future of façade systems.

Use of Glass in Green Buildings

Glass is an excellent material to allow daylight to come inside the building. However, due to its transparency and you can have a lot of solar energy coming inside. However, if positioning glass smartly such as placing a glass on the south elevation where you would get daylight during day time. Solar control coatings and shading devices can also be used as means to limit the amount of solar energy to prevent overheating with an adequate ventilation strategy. Somayah elucidates that glass generates minimal environmental impact. Based on a complete lifecycle approach, the impact of manufacturing the building materials, as well as the construction and demolition phases, become critical to improving a building’s sustainability. In this respect, the minimal environmental impact makes it a choice for sustainable buildings.

The Market for Cladding Materials

The market is still very competitive, particularly coupled with the fact that sustainable construction plays a critical role. More new technologies or cladding materials would emerge in the market. “Recently, I’ve seen a cladding system stating it does not require any metal subframe which therefore achieves excellent u-value as a selling point”, she adds. Somayah explains the technical aspects involve structural issues, architectural concerns, and aesthetics, as well as functional matters. Finally, the social aspects refer to the acceptance of the element by building users and architects/engineers, while the financial aspects interrelate the ownership with the economic incentives and the investment feasibility.

Conclusion

A building’s cladding can contribute distinctive, visually pleasant architectural aspects. Additionally, the cladding may help with other useful architectural improvements, such as creating a wind and rain barrier, enhancing acoustic and thermal insulation, and enhancing a structure’s resilience to fire and flood. Today, there is a wave of sustainable and green buildings with safety features going on. So, the architects, builders, developers, and consultants have started choosing cladding materials carefully and wisely.