Shape, colour and material all convey emotions, tell stories and inspire new ideas. FunderMax India offers a host of cutting edge building exterior solutions and is well-known for their cladding products. The state-of-the- art panels, manufactured in Austria, effuse elegance with tasteful patterns that can enhance the look of all kinds of outer surfaces. Max Exterior is a high-quality construction product which is used especially for long-lasting balcony and façade claddings and has extremely effective weather protection qualities. The range of applications with Max exterior is becoming increasingly wider, and the range of decors is also achieving continually new dimensions in terms of nuances and variety. The Exterior panels are duromer high-pressure laminates (HPL) that are produced in lamination presses under great pressure and high temperature.

Celebrating the brand’s 10th anniversary in India this year, FunderMax, since its flag off in the country, has come a long way. In a conversation with Dr. Prashanth Reddy, Managing Director, FunderMax India Pvt. Ltd., we gathered insights on their products and projects, on the progress of façade cladding industry in India, FunderMax’s contributions to the same, and much more. Here are the excerpts from the interview.

Could you please tell us about FunderMax as a global brand and your products?

FunderMax is an Austriabased company. Today, we are considered as leaders in the exterior cladding industry. We have five factories in Austria and operate in over seventy six countries. We have products for both, the interior as well as exterior applications. But in India, we are focused more on the exterior application segment.

It’s been ten years since you have established yourself in India. Could you please tell us the difference between when you introduced your first product and now, and how the conditions have changed?

When the company was started in 2008, the country was facing the financial crisis due to collapse of international finance institution like Lehmann brothers and there were a lot of uncertainties in the market. The demand from the industry was very low. It was probably a good opportunity for us to come in at the time, so the architects had more time and we could engage with them and we could look for some reference projects.

The drawback was that the architects were not open to receiving world class products, especially the premium material. We took that as a challenge and started working on a few reference projects. The sustainability of these projects opened up opportunities for our products, especially for an exterior product. The industry started noticing the products and we started getting more and more opportunities. Today we can proudly say that our architectural products are widely accepted.

How good was the response over the years?

Response was poor to start with, but over the period of time, it got better and better and today we are well received in the industry. Today, while meeting an architect, he/she has a far friendlier approach. They receive us very well and many a times, architects are very happy to know about our products because they are looking for world-class product like ours. The interaction is more from products to the possibilities of various applications & to deal with complex façade designs.

WFM: Have been with the company since the introduction of FunderMax in India?

Yes, I have been lucky to be the first employee of the company in India.

How many products did you introduce in 2008 and how many are there in the market right now?

From the product point of view, we have always been into exterior products. But yes, what has changed in the decades is that we launched a new collection two years back. Today we are proud to say that we have over 30,000 SKUs which we are offering to the market. In the whole process of the journey, it’s not only the products, we have scaled up on application capabilities too. We deal with complex facades, and are able to provide design support. We are also able to handle large projects. Our partners are well trained and toned, and they are able to scale up.

What are the factors which inspired you to introduce FunderMax products in the Indian market?

The advantage of the Indian industry is that Indians are globetrotters today. Our architects are travelling all over the world. They visit different international industrial fairs, and exhibitions showcasing building materials. At the same time, the prospective customers too are travelling across the world. So, this means that both – clients and architects- have good exposure and are looking for adapting same world class products into their projects too.

Coming back, from the company’s side, our design team travels across the world, attending many trendsetting fairs and they learn a lot from these events. Some of these events are able to bring a connect to the architectural requirement. Normally, to bring in a new collection, it takes five years with over 20 designers working on it.

Are all the products of FunderMax available in European markets are sold in India too? Is it accepted in the same spirit? Is your business in India comparable with the same in western countries?

What we have been able to establish is that we are using the same world class products, same list of services, be it India or anywhere in the world. The additional effort of what we are doing in India is that we are trying to be a complete solution provider here, which is quite unique. We are providing support for installation which is missing internationally because the markets there are quite mature and the ownership of the fabricators to comply with the local building codes is very high. 99 percent of our product’s installation is done by our own trained business partners, who are not fabricators otherwise.

Are your company participants, employees, trained from abroad or you train them in India itself?

We do both. For the product training, to understand the production facilities and the quality systems what we have, we do it at our factories in Austria. This also helps them to see the product manufacturing and the level of quality of our products. Rest, in terms of the installation techniques, hands down approach is followed in India. We have a training centre at our Bangalore office and it’s mandatory that all our partners undergo the induction training.

Could you please tell us more about your facilities for both production as well as training?

As far as the production is concerned, our factories are in Vienna, Austria. For the facilities, we have hundred percent subsidiary operations in India. We have our own application engineering in-house team who provides both design and engineering services. Our 44 trained business partners across India can also handle installation and also give pre-sales & post-sales support. FunderMax India’s strength itself is a team of 37. Globally, we are a team of 1000 people.

What is the business percentage in India as compared to the global business that FunderMax has?

Our business here is certainly relatively low because we started quite late in India. We are one of the fastest growing companies for the group and are in the top 5 in the market as far as exterior applications are concerned.

Could you please tell us about your company’s investment in architectural product development and manufacturing?

Currently, the manufacturing is not yet taking place in India, but we are open to manufacturing in the future. We continue to invest in the market. A major portion of our budget is spent on growing the market in India. We do participate in a number of trade fairs and even architectural events. We also invest a lot in training and development. Since we deal with a large share of unorganised market, training and development are quite important on the installation front.

Tell us about your ten year journey in India?

It’s been a very proud journey that we all at FunderMax India share. It has been a collective team effort along with our partners without which the same success wouldn’t have been possible. We are happy and proud about the 10,000+ projects we have been able to realise during this journey. Today, we are a well-known product and a brand, associated with well-known architects, developers and corporate world. Our journey has just begun and we still have a long way to go. We have done projects across India & also grown our presence even in Sri Lanka and Nepal.

Could you please tell us about the advantages of using FunderMax cladding as an exterior product?

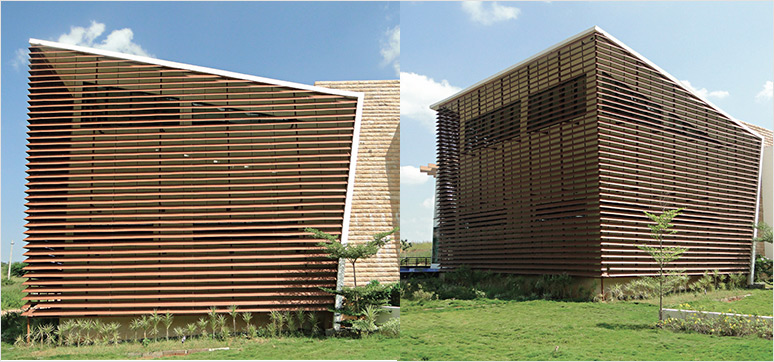

Firstly, it is a world class product with the best of quality and sustainability. Secondly, we also do a ventilated façade system which is also quite unique to India. It is very good for the thermal insulation of the building, making it an energy efficient façade. Overall, it is a sustainable product as well as the installation supports it for the overall efficiency of the building and in the process, enhancing the life of the building protecting it from all external weather conditions.

How does the product help in improving the aesthetics of the building?

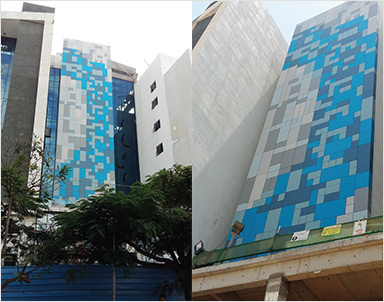

For any application, worldwide, the basic purpose of cladding is more functional rather than aesthetic. So, first of all what is important is functional requirement and then the functional requirement would be supported by good aesthetic looking material. Overall, we were able to deliver sustainable façades for the building. And more importantly, we are able to give a character to the building in terms of the vibrant facades that we offer.

People are wanting eco-friendly, conserving buildings these days. With the use of FunderMax facades, how can they achieve their goal?

As a product, we are a green building material and with our ventilated façade system, it brings more value to make it a green building material.

While talking about sustainability, the source of raw materials contributes to its quality. The raw material used for the production of our products – the wood – comes from responsibly managed forests. The wood used is Forest Stewardship Council (FAC) and Programme for the Endorsement of Forest Certification (PEFC) certified. So, it’s a renewable wood based product and we ensure that the environment is considered. This already contributes in terms of certain points for qualifying ourselves as a green building material.

Could you please tell us how the use of this product has advantages when you are considering the acoustics of the building?

Acoustics properties also depend on the design of the project. Our products have acoustical properties but we have to add some design element along with the kind of insulation we provide. All these elements are incorporated based on the requirement of a project.

How does your product help in building advance façade system?

For the people who create, it is not only the product, but it also the opportunity we give, in terms of design freedom and creativity. We are talking about the architects and designers here. Combined with our world class engineering and the designer’s creativity in architecture, we are able to create very unique façades, which in the end have got some character. And then comes in, the whole performance of the façade, which, in our case, is a highly sustainable.

Our oldest project, which is in Mumbai, is already 15 years old. Those days In Mumbai, it was quite a challenging condition. It is a multiplex hub called “24 Karat” designed by renowned architect Nitin Killawala and today it is a very good testimonial of sustainable performance.

Could you please talk about your recent projects that have got a fantastic response from your clients in terms of climatic response and energy conservation?

We have a lot of fantastic projects which are highly sustainable. But because of the NDA (nondisclosure agreement) we are not in a position to officially talk about the projects. We are, however, working with many leading corporate houses, IT companies, developers, hospitality, infrastructure sector and with many leading and renowned architects.

Tell us about some of your recent projects?

We are working on projects with corporates like Infosys, Wipro, TCS, Reliance, Adani& BASF to name a few. We are also working with the hospitality industry like Taj, Hyatt, and soon. And when it comes to developers, we are doing projects working with Prestige, Brigade, Mantri, etc. in Bangalore and DB Realty, Lodha, Satellite and many others in Mumbai.

Kindly brief on the façade market in India?

Façade market in India is still largely an unorganised one. I would say that 2/3rd of the market is still an unorganised sector. With events like ZAK World of Façades and a number of other organized engagements within the industry, we see a transformation happening and the share of organised market is growing year by year. It is still a large market with a huge potential. There is space for every organised player.

Could you please give us some figures on the organised market for facades in India?

100 million square metres are the potential market for both, facades and glazing in India. In terms of currency, it will be difficult to give a number because we are considering both glazing as well as other materials, we have a choice of materials to play. But this is in terms of the area.

Could you please tell us something about the quality control procedures which you follow for your material, as well as for installation?

We certainly adhere to the National Building Code of the Indian Government. Over and above, we make sure that we follow the best international practices in terms of the quality compliances and for ensuring sustainability.

Do you think that the latest implementation of RERA would help the quality control and builders will go for quality and brands under the organized sector?

This was a very good decision which has happened to our industry. Every organised player will benefit from this and such development gives an opportunity for people to move from the unorganised sector to a more organised sector. Such acts protect the consumer interests which are of paramount importance to the suppliers. We are in favour and support the RERA.

Your products are made in Austria. Indian climatic conditions are very different from what you experience in Europe. So, what kind of treatments is given to your products to accommodate the Indian climatic conditions?

Though the products are made in Austria, we sell them in over 70 countries worldwide which deal with extreme weather conditions. In India, the relative difference between the highest temperature and the lowest temperatures is not less than 40 degrees Centigrade between the warmest and coldest conditions. Take Delhi for example, the temperature in winter is 4-5 degrees and in summer it is close to 47-48 degrees. So, the variation is 40-44 degrees. The winters in European countries such as Austria, it goes to -20 degrees in winters and in the summer the temperature is as high as 40 degrees. Here we are talking of a variation of 60 degrees already and thus the condition is worse in some of these countries than unlike in India which has largely the tropical weather. Our products are made for all weather conditions.

Indian market is highly price sensitive. How successful have your products been? And how have you been able to optimise your sales in India with this constraint of cost sensitive market?

We definitely acknowledge that India is a price sensitive country and within India there are markets which are more price sensitive, like markets in the East. Within this large market, there are many valuable customers who want to use the world class products, best of services and this contributes to a significant share. As long as we are able to connect to the customer and show them the benefits which go beyond just the features, we are able to gain from here. If you want to add a skin to the building and if we do the cladding, it would surely enhance the life of the building. As long as we are able to deliver those benefits and values, the price is a discussion we can certainly address. It is true that we still have to respect the pyramid and focus on the top segment of the pyramid which is still a big market.

What are the key aspects to be considered while going for a cladding material?

We definitely acknowledge that India is a price sensitive country and within India there are markets which are more price sensitive, like markets in the East. Within this large market, there are many valuable customers who want to use the world class products, best of services and this contributes to a significant share. As long as we are able to connect to the customer and show them the benefits which go beyond just the features, we are able to gain from here. If you want to add a skin to the building and if we do the cladding, it would surely enhance the life of the building. As long as we are able to deliver those benefits and values, the price is a discussion we can certainly address. It is true that we still have to respect the pyramid and focus on the top segment of the pyramid which is still a big market.

WFM: What are the key aspects to be considered while going for a cladding material?

The sustainability of the material is very important. The facades should be living and breathing skins. In India, maintenance is a big issue. So, one should look for materials (like FunderMax) which has got minimum maintenance issues. So, this is big value-added advantage. Another thing is the post-sales service and support which we offer. That also makes a big difference. We keep visiting our projects to check for technical compliances and engaging our customers regularly. We are here in India as a fully subsidiary company and not just like an importer. So, we take ownership of our projects and we are here to stay.

Could you please tell us about some of the challenges which you have faced over the past ten years?

Challenges keep coming all the time and also interestingly also keep changing time to time. We operate in highly dynamic macro-environmental conditions. In the past, we had faced some financial crisis, then we had issues of excess building unit inventories, followed by issues of introduction of new acts like GST, RERA and all. We take every challenge as an opportunity and we have tried to overcome them and create prospective business for ourselves. For sure, we’ll keep seeing new challenges in the future too, but the approach of FunderMax has been to embrace these challenges and look for opportunities within these challenges.

Where do you see your company and the façade business in India by 2020?

We are quite positive and looking forward for the market to grow bigger and bigger. There are definite opportunities for organised players as far as the market shares are concerned since they are increasing. We are currently in the leadership position and we would definitely be keeping our heads high by 2020 and beyond too.

Tell us about your future programmes and plans for more facilities? What is your aim for 2020?

We will continue investing in training and development facilities in India. We are definitely keeping all our options open for the manufacturing facility in India in the future. But this also has to be in sync with the global requirements and global brands. We will think about the manufacturing facility depending upon the market conditions of Asia. So, our expansion plans should address the markets beyond India as well.

Do you look forward for any collaboration with other products in India or outside to improve your business?

We have a very vast product portfolio within FunderMax with various application possibilities. And this itself gives various possibilities that we can work on. Today, we are already looking into laboratory business, we are talking about cubicle business and we are also looking for opportunities in modular kitchen furniture. We are exploring the portfolio that we have. Therefore, we don’t have to go beyond our product range to partner with anyone else with the products at least. But within our product portfolio and existing partner work, under our network of what we have, we have lots of opportunities to scale up our business.

We have a very vast product portfolio within FunderMax with various application possibilities. And this itself gives various possibilities that we can work on. Today, we are already looking into laboratory business, we are talking about cubicle business and we are also looking for opportunities in modular kitchen furniture. We are exploring the portfolio that we have. Therefore, we don’t have to go beyond our product range to partner with anyone else with the products at least. But within our product portfolio and existing partner work, under our network of what we have, we have lots of opportunities to scale up our business.

What is your take on Façade Safety?

Well, we think the hot topics today is the recent fire accidents that have happened in London and Dubai. Looking at the projects in India, façade safety is the area where the industry should really grow and truly work towards maximum safety. We should not wait for the accidents to happen and then work out for solutions. The industry should work together to strengthen our National Building Code so that our buildings are safe in the first place and able to handle any unfortunate fire accidents.

FunderMax products have flame retardant as well as fire retardant features, which can contribute to the safety of the buildings. We are definitely working with the other leaders of the industry to make the buildings safer. This is one area, where I think the industry should be quite proactive in their approach.

At this moment, we are thankful to the industry with whom we have been able to work with and the opportunities that it has provided and we would like to continue partnering with the industry.

According to your clients what is your success mantra?

We believe in focus. We do not want to jump into every opportunity we see. We are highly focused on our approach. We are clear about our markets and our potential, we are clear about our customer segments, and our potential cost and we remain focussed on that.

We believe, our partners make a big difference to our success. They have stood with us for ten years and look forward for the association for many years to come. Their abilities to support and service these ten thousand projects have made a big difference and contributed to our success.