Fire safety design of buildings has been seen as a major focus point due to several building fires in recent times globally. Many innovative building designs now utilize fire safety engineering rather than having to rely solely on functional-based codes. This approach can enable architects to achieve innovative, cost-effective designs while meeting fire safety design needs.

Successful fire safety design requires an understanding of a wide range of issues and components, and the interactions between them such as, fire source, smoke movement, heat transfer to the building structure, detection, human behaviour and toxicity. This article illustrates various phases of fire safety designs from the design, details and materials, etc., in particular from the façade and cladding works aspects.

Phases Of Fire Safety Designs

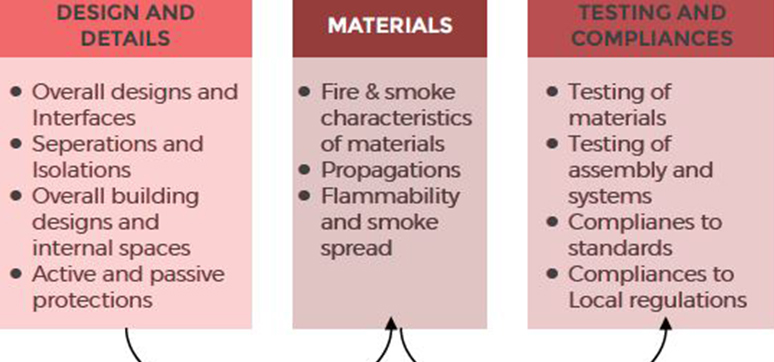

Fig. 1 illustrates various phases in which fire safety designs are part of the design and implementation process such as design, material selection and implementation phases.

Fig. 1: Various Phases in which Fire Safety Designs are Part of the Design and Implementation Process such as Design, Material Selection and Implementation Phases

Fig. 1: Various Phases in which Fire Safety Designs are Part of the Design and Implementation Process such as Design, Material Selection and Implementation Phases

Impact On Facades

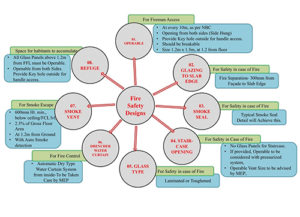

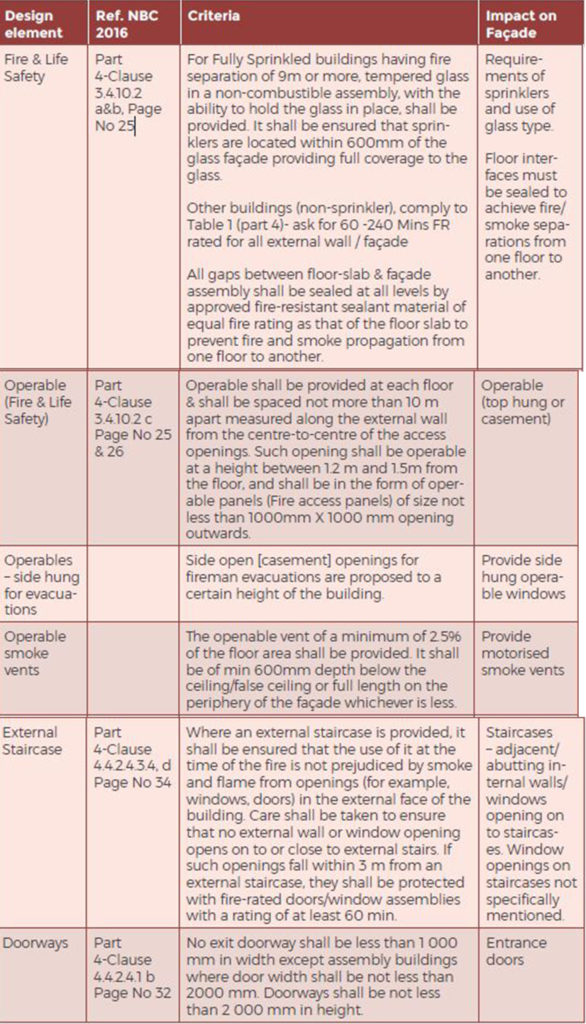

Fig. 2 illustrates various design elements that will have an impact on fire safety designs, some of these aspects are being covered under NBC 2016 and CFO (Chief Fire Officer) regulations. These aspects will have an impact on overall building designs and internal spaces.

Ventilation

Ventilation provides an exchange of polluted air for fresh outside air or clean air from neighbouring rooms. Ventilation requires airflow between the interior and exterior. Thus, it is necessary to start and maintain airflow according to requirements in a ventilated space. Basically, the pressure difference is a force starting an airflow. Active protection systems will help to ventilate the internal spaces and prevent fire propagation and help smoke evacuate. There are standards such as NBC specified for the required area of façade openings. There are several types of ventilation such as natural, mechanical and hybrid ventilation.

Smoke Vents

Mechanical ventilation system integrated with BMS (Building Maintenance System) are automated such that these vents are open automatically in the event of a fire or smoke detection. Smoke vents are installed on a building façades/envelopes as an active fire protection measure. They are the openings in the windows/façades or sometimes on the roof, which are intended to vent the heat and smoke developed by a fire inside the building by the action of buoyancy, such that they open with gravity or actuators connected to fire protection or smoke detection systems (Fig. 3).

Sizes, locations, etc., are specified in the NBC or respective local fire norms such as CFO requirements. As the general guidance codes recommend that openable vent of 600 mm height be installed below ceiling level or false ceiling level (if provided). The openable vent of a minimum of 2.5% of the floor area shall be provided. It shall be of min 600mm depth below the ceiling/ false ceiling or full length on the periphery of the façade whichever is less. Openable mechanical devices for the said vent shall be located at 1.2 m height from the flooring level. The operable vent can be pop out type or bottom hinged provided with a fusible link opening mechanism and shall also be integrated with the automatic smoke detection system.

Brookfield – A Commercial Project at Bengaluru

Brookfield – A Commercial Project at Bengaluru

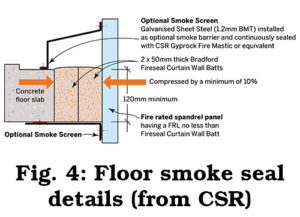

Design And Details

One of the key details of the glazing system is floor interfaces which should stop fire and smoke spreading above floors in the event of a fire. This is referred to as perimeter sealing and the following figures (Fig. 4 & Fig. 5) shows standard good practice details widely adopted.

Materials Generally

Building with fire-safe products can help enhance resistance to heat and flame during a fire. This fire resistance can slow the spread of a fire, reducing property damage and allowing additional time for egress. From roofing to windows down to the structure of the building itself, choosing fire-safe materials can help protect the property and life. The design featuring on the building envelope has mixed-uses with several materials covering a significant area of the building.

Hence, the usage of appropriate materials and understanding characteristics of each of the material and its overall assembly is critical in achieving good fire safe designs. A fire-resistant material is one that is designed to resist burning and could withstand heat, however, fire-retardant materials do not support or propagate fire. Hence, the designer has to understand the applications of ‘fire resistant’ and ‘fire retardant’ materials and their assembly.

Cladding Materials

Material selection for building envelopes is often complex but yet a key decision. With wider options available, often the selection of the right material requires wider knowledge. We have been witnessing buildings with highly flammable and dangerous materials used without any details reviews. We have also seen advertent compromises in the choice of right cladding materials to cut costs and other commercial reasons. In these situations, building envelope, which is supposed to provide long-lasting maintenance free façades, becomes a risk to occupants. Recent Grenfell tower has given unforgettable lessons to the whole world.

We continue to see similar cladding fire in several regions, notably UAE/Middle East has experienced several high-rise building façade fires such as Address Hotel, Torch Tower, etc. However, the highly devastating fire like Grenfell tower has never been witnessed by humankind. It is time for design professionals and investors/developers to deliver safer buildings.

Several regions do not have adequate local regulations to control the inappropriate use of building materials. However, local regulations alone can’t be relied upon for safe designs. The failures in checking and enforcing the right materials lead to severe consequences to a precious life. Hence, self-regulated building industry, responsible designers and developers need to focus on safer buildings.

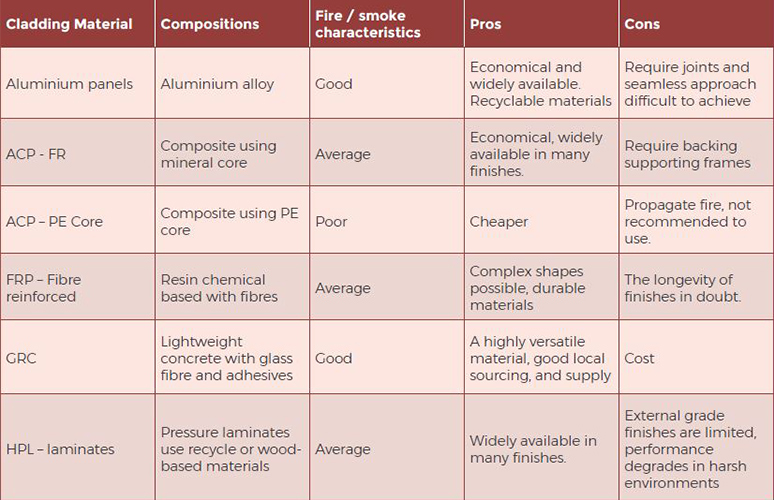

The table below (Table 1) illustrates some commonly used cladding materials and comparison of their fire characteristics.

Table 1: Some Commonly Used Cladding Materials and their Fire Characteristics

Testing And Standards

Several international standards commonly referred to testing and compliances for fire safety designs, some of these standards are presented here.

a) BS 8414- Fire performance of external cladding systems a. Used for testing the cladding assembly system on a full-scale fire testing to determine the fire and smoke spread.

b) ASTM E119- Fire tests of building construction and materials

c) EN13501- Fire classification of construction products and building elements. Classification using test data from reaction to fire tests

d) NFPA 285- Standard fire test method for evaluation of fire propagation characteristics of exterior wall assemblies containing combustible components

e) ASTM E1354- Standard test method for heat and visible smoke release rates for materials and products using an oxygen consumption calorimeter

f) BS 476 – Part 6 & 7, Fire test to building materials

g) ASTM E 84- Standard test method for surface burning characteristics of building materials

h) ASTM E 2307 – 04 Standard test method for determining the fire resistance of perimeter fire barrier systems using intermediate-scale, multi-story test apparatus

Indian Standards

The table above summarizes National Building Code (NBC 2016) relevant clauses (extract) of fire safety designs on building façades. For more details, please refer to NBC 2016 Part 4 and 6.