Architectural Hardware

With the entry of international systems, equipment and hardware firms, the Indian architectural hardware for façade and fenestration has also evolved over the years. Technology and its use have increased many folds giving precision to products with quality and sustenance. Along with the use of technology, design has also evolved over the years.

Gone are the days of highly reflective glass, strip windows, and punched openings for high-end commercial facades… at least for now. The trend for buildings to have more transparency has been taking precedence in metropolitan areas over the past few decades. This has fueled the designer’s interest to continue to push the boundaries of what is possible with lighter support structures, taller unsupported facades, and fewer hardware/connection points. One of these avenues for progressive design is the resurgence of the highly transparent facades.

In this article, we shall discuss the hardware which permits such transparent façade systems. The three major hardware systems discussed are Point Fixed Façade Architectural Hardware, Structural Glazed Façade Architectural Hardware and Modular Post Railing Systems.

Point Fixed Façade Architectural Hardware

Point Fixed Glass Systems are used most frequently in the structural curtain walls to create transparency and depth of vision for the occupants. The glass panes are either bolted or clamped with components providing attachment to the structural system. The most common system type is often referred to as the “spider” system or the “clamped” system. The metallic fingers that support the glass facades allow the designer to increase the transparency by minimizing the structural framing. This four-arm fitting is usually a stainless steel casted material supported mainly with the following types of supporting system:

- MS pipes/boxes.

- Fins Metal/Glass.

- Tension Rods.

- Tension Cables.

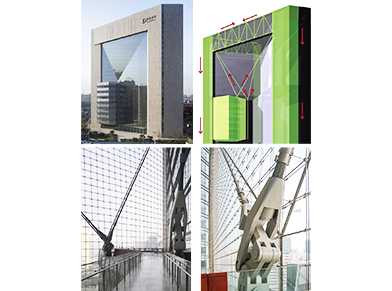

Tension cable/rod facades are another sharp-looking solution to make the transparency of glass the stand-out feature, thereby further minimizing the visible structure from the inside and outside. The two main types in the industry are tension rod facades and cable net walls.

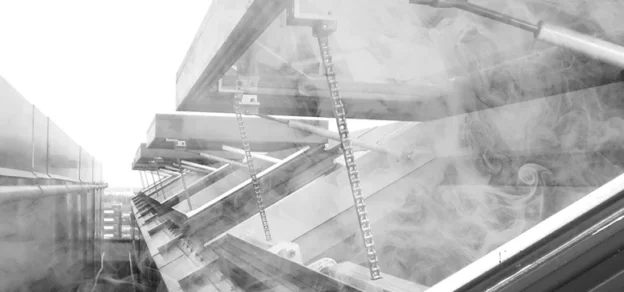

Cable nets represent the ultimate in elegant minimalist structural systems, and provide optimum transparency when the effect of a sheer glass membrane is desired (Image -1). Frei Otto developed and popularized cable nets as a structural system in the 1960s and 70s. However, it was architect Helmut Jahn and engineering firm Schlaich Bergermann that applied the technology in a most innovative manner for the Kempinski Hotel in 1992. The Munich hotel’s flat cable net-supported glass facade fueled worldwide interest in cable nets as a structural form in glass facade applications.

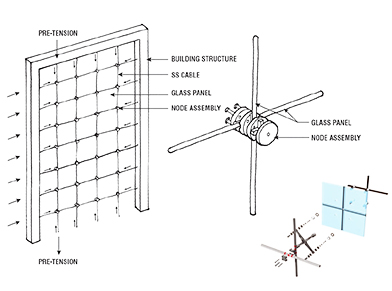

This structural system supports glass by a net geometry of pre-tensioned cables (Image 2). Designs can be flat, or the net can be pulled into double curvature. A clamping component locks the cables together at their vertices and fixes the glass to the net. The net structure’s large pre-stress load requires early coordination of the facade contractor with the building engineer (Image 3).

Cable pre-stress must be applied in the field via complex hydraulic jacking processes. Installation means and methods are a primary consideration for all cable structures.

Structural Glazed Façade Architectural Hardware

B.1- Cast in Channels

Introduced in Europe, cast-in channels are one of those fixtures that can boost the installation speed by 2 to 4 times and at the same time provide much higher structural stability, Why so?

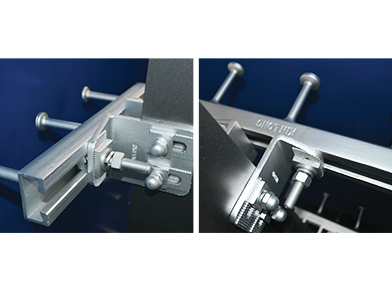

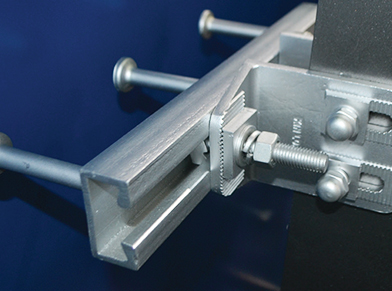

Cast-in channels are rolled channels with swaged studs that are cast into concrete walls (Image 5). These also could be a one-piece casted unit in materials such as Stainless Steel of Grade A4/A2 or Carbon Steel with the coating of Hot Dip Galvanizing or Dacromet coating.

This fixing system allows practical fixations into walls, slabs, beams and columns that securely transfer the loads onto the building’s substrate. T-head bolts and lock nuts are available to allow secure and easy connections to the cast-in channels (Image 6). The use of this system is applicable in a wide range of construction works. Cast-in channels are first secured to the formwork at designated positions. Channels are provided with filler to prevent the concrete from entering inside the channel slot.

The filler is taken out after the concrete has dried and connections are made with corresponding T-head bolts and lock nuts at desired positions. 3D adjustability is achieved through flexible design. The use of cast-in channels for connections offers great advantages. The safe and reliable attachments with easy and quick production times lead to faster completion of the construction works. The result is a quality finish at lower costs. The requirement of pre-design and prefixing in construction offers great advantages.

B.2 – DACROMET® Coating System

DACROMET® is the leading inorganic coating commonly specified in the wind turbine, heavy truck, marine, agricultural, construction equipment and aerospace industries. A water-based, VOC-compliant coating, DACROMET® is comprised mainly of overlapping zinc and aluminium flake in an inorganic binder.

DACROMET® is usually applied to small and medium-sized metal components such as fasteners and stampings which can be coated in bulk by the dip-spin process “Dip-spin” refers to an application process whereby the product is placed in a mesh basket, submerged in a coating solution, and then spun centrifugally to remove excess coating material. Each application step in the DACROMET® emulsion is followed by a 15-minute curing cycle of the base coat at roughly321°C (610°F) part metal temperature. Once the sealer is applied, also by spray or immersion, the parts undergo a 15-minute curing cycle at roughly 177 °C (350°F) part metal temperature. (Image 7).

Typical coating thickness can range from 6 to 12 microns. Coating thickness may be varied through successive applications of the base coat and by controlling the viscosity of the DACROMET®emulsion. The coating coverage by this process is very smooth and uniform. For projects requiring corrosion protection, DACROMET® is recommended. DACROMET® sealers typically with standing excess of 1000 hours of salt spray exposure per ASTM B117. DACROMET® coating standards are specified in ASTM F1136 and F1136 M (Image 8).

DACROMET® coating standards are specified in ASTM F1136 and F1136M.

Four-Way Corrosion Protection

- Barrier Protection: Overlapping zinc and aluminium flakes provide an excellent barrier

- Galvanic Action: Zinc corrodes to protect steel Passivation: Metal oxides slow down the corrosion reaction of zinc and steel

- Self-Repairing: Zinc oxides and carbonates migrate to the damaged area to repair and restore the coating

Dacromet® Advantages

- Thin: DACROMET® is 5-7 microns and DACROMET® L is 7-9 microns

- Hydrogen Embrittlement-Free Process: Coating does not require acid pickling or electroplating

- Bimetallic Corrosion Resistant: Aluminum flake eliminates the typical bimetallic cell of zinc coatings

- Solvent Resistant: Inorganic nature causes it to be resistant to organic solvents

- Heat Resistant: Maintains corrosion resistance even following an intermittent heat shock

- Conductive: Concentration of metallic flake allows an electrical current to be passed

- Salt Spray Resistance: 1,000 hours

- Better Than Pure Zinc: 3 times greater corrosion protection than pure zinc.

Environmental Benefits

- No Toxic Metals: Free of nickel, cadmium, lead, barium and mercury

- Water Based: Free from dangerous solvents

- VOC Compliant: Under EPA RACT requirements

(Courtesy – http://www.matenaer.com/Products/Metal-Finishing/DACROMET.htm)

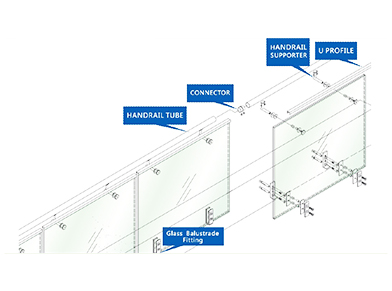

C) Modular Post Railing Systems

Think of balconies in buildings, glass & supporting systems are equally important. The standard norms of the market allow for distinguishing the glass types and the patterns. Similarly for the railings, important is the safety, maintenance and ease of installation. We have a seamless

railing systems using channels or spigots, the point fixed railing systems using hollow or plate balustrades & the cable/rod supported balustrade balconies (Image 9).

Considering a balcony, laminated glass is a high priority with a SENTRY interlayer or at least the PVB, with a minimum thickness of of12.89mm (SGP)OR 13.52mm(PVB) (subject to axial loads), Recommendation as per the European market states it as 17.52mm. Now, the hardware part, designed to take loads is primary and secondary is the aesthetics, a factory-made finish can be easily ruined at the site if any further fabrication takes place (Image 10).

A cold rolled Stainless Steel grade not less than 304/316/316L/2205 is recommended, Wood and coated Aluminium are also considered as per requirement. Talking of Installation, how do we make sure that the factory finish is maintained at the site? There are systems available that are plug-and-play type, totally modular and have no chance of welding or grinding (Image 11).

The installation is 3 simple steps.

- The floor and base plate/ channel are to be enjoined using the anchor bolt after drilling the holes; the supporting structure is then fixed(Images 12 & 13).

- The glass installation – Glass will either be embedded (in channel) or have holes in it(point fixed type), using the Allen key on the outer or inner covering of the brackets or clamps can be tightened to lock the glass.(Image 14)

- The top pipe/c channel will get fixed to either the balustrade or the glass directly using the rivets or double-side tapes respectively. The ends of the pipe should be secured with accessories(Image 15).

Glass facades are impressive and amazing types of curtain walls for the new-era buildings. From the conventional ways to the most sophisticated style, technology has been never-ending. Yet again, it brings food for thought to the reader’s mind Why shall we not try a better system than the previous ones? The old way was new until it was replaced by a better one, Changes are that make us what we are. Let’s be the change to build up our nation into a beautiful & comfortable place to live in.