Could you please explain some of the common causes of fire-safe fires in Buildings in the Middle East?

There are numerous ways a fire can be initiated and continued. However, according to statistical data, the most common causes of fires are associated with “cooking” and “electricity.” Smoking and “deliberately caused or intentional” are also some of the other major causes of fires. In order for a fire to occur, three elements must be present, referred to as the fire triangle, i.e., heat, fuel, and air. Fuel is everything that can burn, even people can be fuel. If fuel is available and heated enough to reach its ignition temperature, it can start burning in the presence of sufficient oxygen (air). The combustion process is exothermic (producing heat) in nature which causes a chain reaction and adds another element to the “fire triangle”, called “chain reaction.” Now, the fire triangle changed to “fire tetrahedron.” Until all four elements exist, the fire will continue to burn and persist until one or more elements of the ‘fire tetrahedron’ are eliminated.

With regards to the Middle East, the causes of fires are no different from any other part of the world, except for ambient temperature that can be higher, which may require to pay special consideration for the finishing material used on the structural and non-structural components of the building. The high ambient temperature may lead the combustible material to its ignition limit quickly, making the fire more rapid. Timing is very critical in terms of fire; a fire scenario may change in a matter of minutes and the fire may become catastrophic even before firefighters arrive on the scene.

How can fire risks be reduced?

The occurrence of fire and its uncontrollable development is attributed to the failure of the different layers of protection. It is a typical case of the “Swiss cheese failure model.” The first layer is the failure of fire prevention measures such as inappropriate housekeeping, increase in fuel load, presence of combustible or flammable liquids in non-designated areas, and many others. Following the proper fire prevention techniques can reduce the risk of fire propagation and the extent of the fire.

The next layer of failures is related to maintenance. For a fire protection system either active or passive, to work as intended, it is necessary to follow the appropriate maintenance program and perform it on a regular basis in accordance with the time specified by codes or manufacturers. For example, it is not uncommon that valves for sprinklers system to be found closed and water did not arrive at the sprinklers, detectors failed to operate, the fire pump did not start, corrosion of pipes, and so on. Adherence to the appropriate maintenance program may reduce the risk of fire and the risk of the fire becoming catastrophic.

The third layer is a proper and adequate design and installation. The designer may have missed important aspects of the design requirements, or the wrong material may be installed, such as using standard sprinklers in areas where special types of sprinklers – for example, ESFR, CMSA – is required. The contractor modified the pipe routing without consultation with the designer. Keeping all layers within prescribed limits and maintaining systems can reduce the risk of fire and the effects of fire on life and property.

Please explain the role of design systems in fire-safe buildings?

Building safety demands the collaboration of many areas of science and engineering. Fire Engineering, includes the fundamentals of fire phenomena and basic principles of physics and chemistry, such as stack effects, buoyancy flow, combustion process, and understanding of the material properties and their reaction to fire. Mechanical, electrical, and structural engineers play a vital role in providing a structurally stable building with proper piping and well-insulated electrical fittings. While ensuring the aesthetic appearance of the building, architects must adhere to the safety requirements proposed by different disciplines.

A well-coordinated project across disciplines at the outset of a project not only reduces the cost of the project but also ensures the safety of the building.

What is the role of fenestration design in fire-safe buildings?

Over the last few decades, the application of modern façade systems has effectively improved the performance of tall buildings as it provides multiple objectives of value to its occupants, such as a cost-effective solution for thermal insulation, and weatherproof (e.g., extensive rain) as well as the building aesthetic. However, because of the existence of polyethylene and other flammable core materials in the façade, such systems have become a route for fire to spread along with the building exterior and caused a number of recent severe fire accidents. Moreover, during a façade fire, the toxic smoke which enters the building (through cavities, windows, or any other openings) can make occupants incapacitated and limit the egress time. For example, the recent tragic event of the Grenfell Tower fire in London in 2017 had claimed more than 70 lives.

For proper lighting in “green buildings,” glass walls are provided as the exterior of the building. While this is an excellent solution for “energy savings,” in the event of a fire, the failure of the glass can lead to a very critical and serious phenomenon called backdraft (sudden burning of superheated gases due to rapid entry of the oxygen), which can turn the fire in an inferno and put the life of occupants and firefighters in danger.

What are the passive and active fire-safe protection methods?

Passive fire protection methods are those that have no direct involvement in the suppression or control of the fire, instead, they confine the fire within a specific region and limit the spread of fire. Compartmentation, fire resistive coating on walls, ceilings, or floors, and fire doors are components of passive fire protection. In contrast, systems that actively participate or act in fire situations are active fire protection systems, such as sprinkler systems which are activated upon sensing the high temperature and try to extinguish or control the fire from direct action. A fire alarm system is also an active fire protection system as detectors detect the changes in environments such as heat or smoke and notify the occupants about the fire and guide for evacuation. The sprinkler systems and fire alarm systems are automatic active fire protection systems. On the other hand, fire hydrants and standpipe systems (hose reels) used by firefighters to extinguish the fire are manual active fire protection systems.

Reaction and fire resistance: How are materials classified in the event of a fire?

Material properties are altered with temperature. Building materials, including those used in façade systems, behave differently at elevated temperatures. All materials must be tested for reaction-to-fire (RTF) to evaluate their performance and response when exposed to fire. It is mainly associated with the combustibility and ignitability of building materials.

Fire resistance (FR) is the material property to resist or withstand the fire and continue to perform its intended function and contain the fire for a specified period. To maintain the compartmentation and confine the fire within a specified area, structural (beams, columns, and slab) and non-structural components (walls) are provided with specific fire-resistant ratings, such as 1-hour, 2-hours, and so on. Designers and engineers must be aware of both properties of the materials (RTF and FR) and the required fire-resistant rating of the building (required hour(s)-rating may vary with the occupancy types such as apartment building, office building, and height of the building). The RTF and FR are integral components of the building’s passive fire protection.

What scenarios could cause an internal building fire to spread to the external façade and other parts of the building? What protection measures are in place to control fire?

The uncertainties associated with fire are enormous. Fire can spread and reach other parts of the building both in horizontal and vertical directions. De-compartmentation is one of the major causes of the fire reaching adjacent compartments, such as the failure of fire barriers and walls. Fire can also reach other parts of the building through false ceilings. In many fires, the fire reached other parts of the building due to the collapse or failure of the false ceilings.

Fire tends to reach towards the high oxygen region (and maintain fire tetrahedron), so it stretches toward the openings. In many accidents and large-scale fire tests, the fire was observed close to the perimeter of the building. Due to heat, glass breakage occurs in the early stages of the fire. Generally, glass breakage temperature is somewhere between 200 – 400o C. From the window opening, caused by the glass breaking, the fire spreads to the outside of the building and ignites the combustible façade, and travels vertically, as observed in the Grenfell Building in London and Address Hotel fire in Dubai.

What is the importance of ‘perimeter fire barrier systems in the prevention of fire spread?

Perimeter fire barriers are one of the most critical elements of fire safety design, which restricts the spread of fire within a confined region of the building. These systems prevent the flames and hot gases from penetrating the lower floors to the upper floors. Perimeter fire barrier systems create a void at the intersection of the floor slab and the exterior wall assembly. Failure of perimeter barrier or unprotected void at the edge of the slab allows the fire to spread on the upper floor. Vertical fire propagation can make the fire difficult to control and, it may require additional personnel to fight the fire. In terms of sprinkler systems, which are basically designed for a single most demanding area in terms of pressure and flow rate, if the fire size increases, the automatic fire protection system may fail.

Brief about the choice of materials considering fire safety.

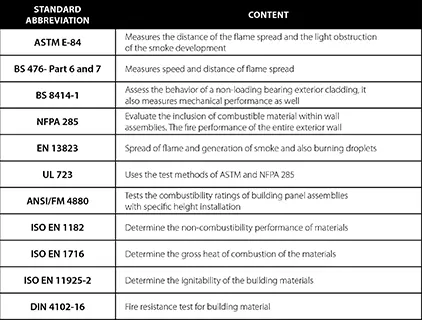

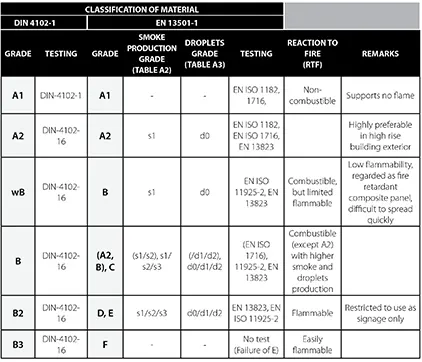

Building materials are chosen based on their fire ratings, such as RTF or RF. I will explain it further using one of the key components of the façade systems as an example, i.e., Aluminum Composite Panels (ACPs). Aluminum composite panels include two layers of aluminum and a core material sandwiched between them. Polymer-based composite panels, such as ACP used in the façade system, are well developed because of their lightweight, formability, and cost-effectiveness. Despite a high fire risk, old buildings and relatively newer buildings in some developing and developed countries still use the ACPs with flammable core material (flammable generally means that the material can support a flaming fire). Based on the RTF, the core materials of ACPs are classified into various grades, as described in EN-13501-1, DIN 4102-1, and other standards. The core materials are tested for combustibility and ignitability.

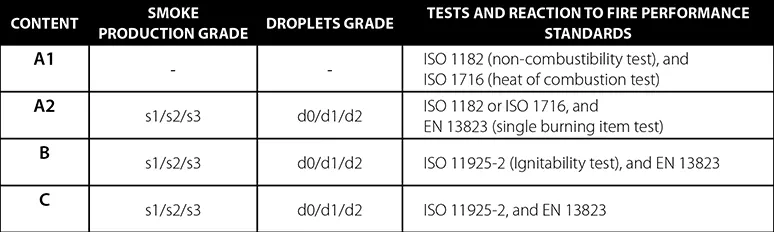

Based on their combustibility, these materials are graded. For example, according to EN-13501-1, the grade-A1 core material must pass the non-combustibility test (ISO 1182) and heat of combustion test (ISO 1716), while grade-A2 must not only pass either of these two tests but also required to meet the requirement of single burning item test (EN 13823). For the grade-B core material, only a single burning item test and ignitability test (ISO 11925-2) are required.

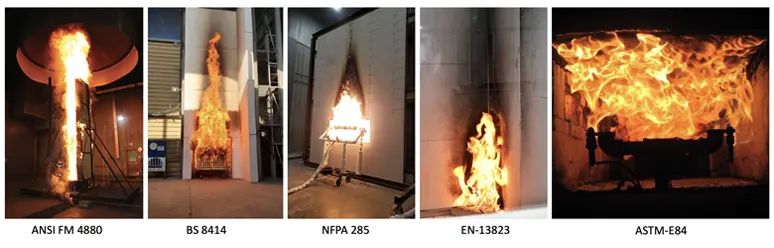

In general, most of these core materials have a certain percentage of ceramics or other non-combustible materials (e.g., mineral matter) to reduce their combustibility, and their utilisation of them is quite common in modern buildings. As the high-cost A1 core materials are rarely used, the “non-combustible” A2 core is a preferable choice for ACPs in terms of fire performance in high-rise buildings. Besides, the B-core materials are also widely used in ACPs and building façades, because they are considered “limited combustible,” although the concept of “non-combustible” itself is questionable. There are various standard methods to test metal composite panels, e.g., ASTM E-84 in the USA with the guidelines of test methods in NFPA 285 and BS 8414-1 in the UK.

Please throw some light on aspects such as façade openings, ventilators, and other façade designs that would help to prevent fire and its spread?

In the façade designs, to limit the spread of fire, one must, without a doubt, use the right material. The right material means; it should not be flammable or easily combustible, or support fire spread. Because of buoyancy, the fire spread is much faster in the vertical direction, and it became more apparent in tall buildings due to the stack effect (or chimney effect: movement of air due to difference in temperature inside and outside of the building). Properly designed ventilation systems help to limit the smoke layer generated in the fire compartment. Due to thermal feedback from the accumulated hot gases, the fire can reach flashover (the condition when all combustible in the fire compartment get ignited). Furthermore, ventilation systems maintain visibility for the occupants and firefighters.

By filling the gaps with the proper fire-resistive material, the fire can be confined within the fire zone, its spread can be stopped and fire may die itself as soon as all fuel (removal of “fuel”: an element of fire tetrahedron) is consumed (in case of the well-ventilated compartment).

Please tell us about the parameters defining the performance of fire-safe façade materials?

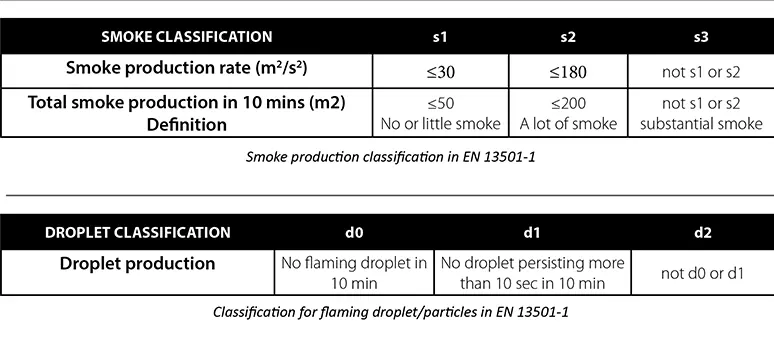

The rating of the façade materials for their flammability and ignitability is provided based on the smoke production and flaming droplet production. For example, according to EN 13501-1, the rate of smoke production and total quantity of smoke and flaming droplets produced in 10 minutes of burning decide the rating of these materials. Materials that produce very little or no smoke and do not show any flaming droplets in ten minutes of the burning test are considered “non-combustible” or “A1” grade. It must be noted that although the terminologies like “non-combustible,” “limited combustible,” and “flammable” are often found in manufacturers’ marketing material, the test standard does not explicitly define these terms.

What do you think about the current fire safety codes for buildings?

I have my views regarding codes and practices. Unfortunately, engineers learn from mistakes and failures, sometimes more than they do from success. The great fire of London is an example of such a case, where nearly the entire population of the city was displaced, and it led the authorities to develop codes and instruction of new provisions to avoid such tragedies in the future. Ever since significant improvement and development have been witnessed in modern codes and standards over time. However, the practices that may be applicable now may not hold in the coming years, given the enormous changes in technologies and the design of buildings and structures. Codes are changing and improving continuously and require inputs from industries and research institutions.

The advancement of computational techniques such as Computational Fluid Dynamics (CFD) may play critical roles in future codes, as seen in the 2016 Edition of NFPA 13, where a relaxation of the installation of sprinklers in cloud ceilings based on the results obtained from CFD simulations is accepted, which I see as a positive step towards the adoption of computational techniques in modern codes. Will the future codes be more acceptable to the CFD modelings? The answer lies in the reliability of the results and validation studies. I also believe that in the future of fire safety engineering, machine learning and computer vision will play a very important role, but for that, we may need to wait a little bit.