Jean-Marc Luvisutto is the Managing Director, SBS (Sapa Building Systems) – Middle East and India. He is associated with the company for the past 38 years, spearheading various divisions including technical, marketing and communication, from various locations (France, Portugal, UK). He is a civil engineer (MSc) from ENSTIMA (Ecole Nationale Supérieure des Techniques Industrielles et des Minesd’Ales) in France. He Joined Technal in Toulouse (France) in 1979 as a product development engineer in the R&D department. From 2000 to2008, Luvisutto managed the entire R&D activity for the Technal Brand. In 2008, he moved to Bahrain to manage Technal Middle East. After the merger between Orkla/Sapa and Hydro in 2013, he took over the management of Sapa Building Systems (SBS) Middle East, and its two additional brands: Sapa Building System and Wicona. Since July 2016, he is as well managing SBS (Sapa Building Systems) India, with the objective of creating more synergies between Middle East and India.

In an Interview with WFM, Jean-Marc Luvisutto talks about the brand Technal, their products, projects, values, their goals and aspirations, and the company’s journey to success. He also discusses the growth and future of façade and fenestration industry in India, and the challenges faced by companies in the façade business. Here are excerpts from the Interview:

Please shed some light on the evolution of Technal in India and the inspiration behind it. Kindly tell us briefly about the company’s journey since its establishment in the country?

The company was first established in India with the brand Domal in the year 1996, in Kolkata, and has been in India for over 20 years. Later, the company moved to Bangalore, and until 2013, Domal in India was belonging to Hydro Building Systems Private Ltd. In 2013, after the merger of extrusion and building system activities of Hydro and Orkla, the company became Sapa BS India Pvt Ltd. Today, Sapa BS India Pvt Ltd – India (Sapa Building Systems India) is the only company that is marketing and selling the Technal brand and Technal products in the Indian market.

However, Sapa Building Systems India also has access to all the products available in other SBS brands (Wicona, Sapa Building Systems, etc.) if needed.

As you said, Technal came to India through Hydro building system. Hydro started off with Domal in India and later on launched Technal. How has been the product acceptance for both the brands in India?

Domal name has been synonymous with Aluminium windows since a very long time and will continue to be so in market like India, considering it is a very cost effective solution for basic-medium performance requirements.

“Agree that Technal is not yet well known in India but it is a leading brand in Middle East and thus very synonymous and appreciated by the Indian fraternity, consultants, contractors and metal builders working there. There is a sense of trust and goodwill already established, this certainly is an advantage for Technal in India.“

We have started introducing Technal more and more since past two years, considering the increasing demands in terms of performance by our customers, and the wide range of solutions available within Technal to meet almost any technical/architectural requirements, and this has been very well accepted by the market, and this is clearly evident in some of our recent orders.

How many verticals fall under Technal’s ambit? What are its complete product range in India?

We have broadly seven verticals, which include sliders, windows, doors, interior solutions, curtain walling, shading & barrier systems, and bullet proof systems The Indian market has been evolving day-by-day and there is a lot of awareness both from builders/ real estate developers to the end users, in terms of creating value, by using high quality products (windows/doors) in residential & commercial projects. This is also driven due to increasing demands for high performance and aesthetics. This makes system companies like us the most obvious choice. From our side, we also do our bit to constantly keep updating the stake holders of all latest developments and possibilities within Technal with our complete product range and capabilities.

In India, the last few years have seen glass becoming the hottest design statement. Please elaborate how mature is the façade and fenestration market in terms of understanding the products and their proper usage keeping the climatic condition of the country in view?

The fenestration industry in India has gone through a sea change in the last few years. The Indian fenestration and curtain wall industry is in an emerging state with respect to technology, capability and size. The facade combines attributes of both appearance as well as superior performance, and the concept is fast catching up in India and apart from the aesthetics, they offer better natural lighting, better weather tightness and are in line with the increasing adoption of green and sustainable building practices. Today, many people associate ‘contemporary architecture’ with glass. With customers becoming increasingly aware of increasing costs on account of bad energy management, newer buildings have a higher percentage of glass on their facades. With technically superior glass that aids in energy management and leads to direct savings in terms of energy bills, the demand for glass as a building material will only increase.

How does your products help in building advanced facade systems? How can we optimise solar & acoustic performance in glass facades?

JML: In addition to the vast range of standard proprietary TECHNAL® products offered regionally, it also offers a limitless possibilities of bespoke solutions customised for projects that requires special solutions to meet the design criteria of the architect and fulfil specific high weathering, thermal and acoustics performance criteria.

Such principles have also been applied to casement applications with SOLEAL MINIMAL where opening sashes have been kept invisible behind the outer frame structure thus keeping both openable and fixed parts with same sightlines.

One of the concerns in the building industry is related to acoustic performances and we are working in our R&D department in finding new solutions and products that could strongly enhance the acoustic performances of the building envelopes. We are not only working on passive solutions by improving the design of aluminium systems (tighter and better, managing vibrations) and incorporating new materials that have better acoustic performances, but also working on dynamic solutions, like in “noise cancelling headphones” that are analysing the external ambient sound and generating “opposite sound’ thus neutralizing big share of the incoming ones (even when windows are slightly open).

We are also developing simulation tools (Tec- Acoustic) that should enable to correctly predict what should be the acoustic performance of the building envelope based on the aluminium system and infills that are used.

- As mentioned earlier, TECHNAL® offers vast range of standard products regionally. Technal Middle East also offers unlimited bespoke solutions.

- We are also very open to new trends in architectural designs, for example minimalistic designs and slim visible structures. It is particularly true for sliding system and TME is already able to provide products (LUMEAL and ARTYAL) giving the maximum share of the surface to vision and glasses, and keeping the structure either hidden behind the wall or reduce to the bare minimum sightlines.

- Last but not least, aluminium is a tremendous material from the point of view of recyclability as we need only 5 per cent of the energy needed to produce it to recycle it (aluminium material can be considered as an ‘energy bank’ as all embedded energy will remain in it). Unfortunately, many other components that are used by the window and façade industry are not as friendly when it comes to recyclability. We are thus also working in R&D with industrials partners to find suitable materials that could replace these ‘non-recyclable’ material with more environmentally friendly ones with the objective of being able to provide in a near future doors, windows and facades that could be 100 per cent recyclable.

Please tell us about your clients and ongoing projects in India? Kindly brief on few of the iconic projects completed in the recent past?

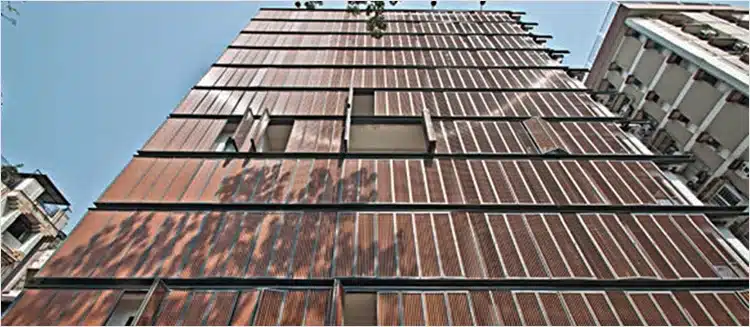

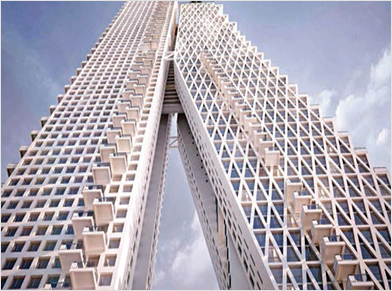

JML: Our client is a mix of high-end residential, luxury villas, and commercial projects. We are proud to be associated with projects like Godrej Platinum Mumbai, IREO Corridors Mumbai, Raheja Vivarea Mumbai, Shristy Hotel, Urbana, Kolkata, etc.

India is considered as a highly price sensitive market. How successful has Technal been able to optimise their prising with respect to the Indian mentality?

JML: For me, every market is price sensitive, and no one pays anything extra unless they see a value. Technal, in line with our corporate principle, continuously adds value not only in our product, but also pays a lot of attention in entire process, thereby making it an overall good experience right from pre-sales to entire execution and goes beyond even after the product is installed. We also continuously work on cost optimizations with our suppliers without compromising on our brand quality.

Technal is a part of SAPA group and SAPA has an extrusion plant set up in India. Does it help the business in anyway? Please elaborate?

JML: Yes, this is a key factor in the success of our business today to have with us SAPA extrusion, which is world class facility, very well known in Indian extrusion market for its seriousness, reliability and quality, and which belongs to the same group. It surely helps with better leverage to turn around any new die in the shortest possible time, and overall product lead times.

Technal has had several management changes in India over the past few years. Going forward, what are the company’s plans to stabilize with respect to their Indian operation?

JML: I would say, things are much settled now. We have a good stable team with us in place now and feel that we are poised for bigger growth in days to come. Our strategy is clear and is to focus only on the Technal Brand (although products of others Sapa brands can be available if and whenever needed).

Technal is a very successful and leading aluminium system brand in Middle East and one of my main objectives is to create as much synergies as possible between Middle East and India as these two regions are having quite similar needs in term of products and services.

In addition to that, a lot of real estate/ contracting companies active in India are also active in Middle East and some of them are already our customers there.

In conclusion, we want to keep working on good quality products of international standards, but specifically catering to Indian Market requirements, and we are well on our way to achieve that.

What are some of the challenges you face in India?

JML: After spending so many years in different places, I feel the challenges are more or less the same, in every market. Viz. How do we add value to our customers and serve them in most satisfied manner, meeting their requirements and at the same time, keeping some kind of competitiveness vs. the local systems at the end of the day, our customers are our biggest asset, and we need to serve them to their fullest satisfaction.

India is an extremely high potential market, and some of the projects I came across are comparable with some I have seen for example in Dubai, London, New York or Singapore. Architects, consultants, etc. are often local ones but there are also the worldwide international practices we are already having relationship and working with in Asia, US or Europe.

Today every city in India is developing very fast and it is not restricted only to metros and one challenge if I have to pick would be how do we extend our reach and be present in as many of those projects in those places, and serve them to their complete satisfaction, with sometimes the limited resources that we have on hand.

In a world, where scarcity of energy and recyclability (waste management) are major issues, conservation will become more and more relevant and put more and more pressure on governments and authorities, we need to prepare for the future by:

-

- Developing new products that will reduce the energy consumption (or even products that will enable generation of energy).

- Developing new products that won’t produce waste materials that will be difficult to eliminate (100 per cent recyclability of doors, windows and facades components).

But the biggest challenge will be to educate and convince all the building construction stakeholders, from governments to architects, metal-builders and consumers, not to go for cheapest solutions, but to look towards the most sustainable ones. They should consider not only short term benefits, but also the benefits for future generations.