India’s rapid economic growth and emergence as a top-tier world economy over the past 30 years have been well documented. This economic growth has necessitated the need for a whole range of construction projects. From a national and regional government perspective, it means new and upgraded transport infrastructure including airports, railways and urban transit systems to support future economic growth. Expansion of healthcare and education provision to improve the health and life chances of its citizens is also seen as a high priority.

The positive impact on disposable incomes has fueled demand for high-quality, privately funded projects from well-built, safe residential accommodation, leisure and retail facilities and the expansion of the hospitality sector to meet the needs of both international and local business and tourism. Within this context, the procurement of architectural ironmongery has always had a low profile, but few items impact more the ongoing functioning, safety, efficiency and use of buildings over their life cycle. The correct specification of ironmongery is not just a requirement for delivering and handing over a project but is essential in ensuring future safety and minimizing ongoing maintenance costs of the building for effective use by both its occupants and visitors.

Architectural Ironmongery & The Role Of The Registered Architectural Ironmonger

Although architectural ironmongery technology and design have evolved over the years, the role of an architectural ironmonger (Reg. A.I.) remains the same. Considering design, security and atmospheric conditions, a qualified AI will also ensure that safety, functionality, accessibility and legislation requirements are adhered to. When choosing the right kind of hardware for openings, it is important that we evaluate the type of building and ensure that the specified products accommodate the user’s needs, which in turn will enhance a user’s experience of a building.

Operators should expect the highest standards of durability and cycle testing from door hardware as some components in high-traffic areas are subject to PROBABLY the most repetitious cycling of any components in buildings. Specifiers demand that manufacturers design durability into each application following rigid architectural standards that should be included in specifications to ensure a proper balance between function and cost.

Use can vary from a few cycles a day to many thousands – for example, airport entrances, large office buildings and department stores, so it is critical that we incorporate an aesthetically pleasing look; durability consistent with the level and severity of use; robust designs that require minimal maintenance; support for building safety and security; and ease of use.

Which Standards Apply & What Should We Be Aware Of?

There are currently two prevailing sets of standards related to door hardware/ironmongery that form the basis of the vast majority of project specifications designed both in India and Worldwide. These are European standards, identified with the EN and CE prefixes and American standards identified as ANSI/BHMA.

European Hardware Standards

The most common standards followed in India today are typically European (EN). European Standards for architectural hardware are split into individual categories for product type consisting of a numerical coding system where each digit refers to a particular feature of the product measured against the standard’s performance requirements.

When specifying architectural hardware for an opening, it is critical that all findings are closely observed to ensure each product is fit for purpose. For example, BS EN 1154 Controlled Door Closing Devices features a 6-digit coding system that provides details on product types, classification by use, test cycles, door mass, and corrosion resistance, as well as definitions, product performance requirements, test apparatus, test methods and marking of products (Ref. Table 1).

All of the aforementioned must be taken into consideration to suit the location and type of opening, interior or exterior mounting, type of closer and fixing suitability, volume and frequency of door traffic, and type, size and weight of the door. Where doors are subjected to high wind conditions, a door closer with a variable back check is recommended. Parallel considerations will be applied when specifying electrified opening/ closing devices.

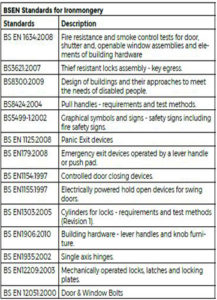

The AI will similarly look at every individual product during specification to ensure that each opening is safe and well-equipped for its required function. Fire and life safety standards such as BSEN 1634-1 door and accessories must also to be considered. Recently this has been taken a step further to CE-marked door sets to BS EN 14351-1. Please see Table 2 for all relevant European standards for hardware and doors in the European codes and standards.

It is important to remember that the passing of the fire test EN1634-1 is not the sole criteria and safety measure to consider when selecting hardware for a fire door. It may pass a fire test in isolation but if it has not passed the remaining EN requirements, the door will not perform the rest of the functions required during the lifecycle of the building to actually be operable in the case of a fire directly causing loss of life regardless of the fact it passed a fire test in a laboratory. Currently, CE-marked door sets have not been introduced into the Indian market, but may well be in the future.

U.S.A. Standards (ANSI/BHMA)

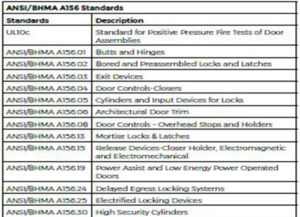

Certain projects often require ANSI/ BHMA standards from the USA such as Airports and other large civil projects. This is due to the far higher cycle and durability testing required to meet these standards, which are typically demanded in such high-use applications.

These are often not readily available (along with the expertise to schedule a specification that conforms appropriately) in the Indian market at present. Due to the typically higher price of these products, it can cause strain on the initial construction budgets that have typically been set with European hardware budgets in mind.

However, this is often a false economy. The ongoing maintenance required for the efficient functioning of these high-use developments means that once the costs of operational disruption, safety breaches, performance failure, and regular replacement and repair of hardware items are taken into account the overall cost argument for American hardware in these applications becomes compelling.

North American hardware specification follows a completely different set of Codes and Standards to that of British / European. Fire Door Standards, Life Safety Codes, and Accessibility Legislation are only a few of the requirements that differ greatly. Table 3 is the same but for ANSI/ BHMA standards.

Ensuring Value, Minimizing Costs & Protecting Lives Throughout The Lifecycle Of Buildings

The cost of facilities maintenance for malfunctioning hardware is considerable, especially in high-use buildings where hardware may fail within weeks or months of being installed. Worse still, security can be compromised and the risks to safety increase dramatically.

Poorly maintained buildings have fatal consequences made all the more devastating due to their easily avoidable nature. We have all seen the consequences of poorly maintained buildings from heartbreaking scenes such as Grenfell Tower, in London, UK where poor maintenance of fire doors and hardware played a significant role in the tragedy.

One of the biggest problems facing the industry is poor compliance to minimum acceptable standards. This manifests itself in several forms with the two most common being lack of over site and accountability for non-compliant products and following non-accredited certification provided from an unrecognised 3rd party testing body.

Unfortunately, poor specification is commonplace with many architectural hardware schedules being either ‘copy and pasted’ from previous projects, or substandard hardware being specified by an unqualified party. All of this can play a part in the false economy (as hardware will fail and have to be replaced) and more seriously, endanger lives, especially when there is such a focus on cost savings being bought to nearly all projects in the current construction climate. We thoroughly recommend that specifying architectural hardware is detailed by a Registered Architectural Ironmonger (Reg.AI) for EN specifications or an Architectural Hardware Consultant (AHC) for North American specifications, thus ensuring that each opening will be furnished professionally.

To ensure your project is fit for purpose, always Remember…

- Always get your specification signed off by an AHC or Reg. AI-qualified hardware/ironmongery consultant

- Ensure all products comply with relevant durability and safety standards and ensure these have been reviewed by a qualified ironmongery consultant

- Always try to use online certification that can be checked to be valid

What Does The Future Hold For Automation & Technology In The Hardware Industry?

Automatic Doors and Access Controls: With the ongoing Covid-19 pandemic and future threats, automated hardware has become integral to minimising the spread of infection, as it lessens the need to touch surfaces, therefore reducing the risk of cross-contamination in public buildings. There are further positive outcomes regarding security with such hardware not requiring on-site security personnel at each entrance.

Integrated access control systems are capable of monitoring and controlling the entry and exit from such buildings. Other forms of access control and remote technology are being introduced into buildings, such as hotels and Air BNB, where people access buildings and rooms via phones or key cards. This has been adopted by several major hotel chains over the last few years and demand will only increase as the technology becomes more affordable.