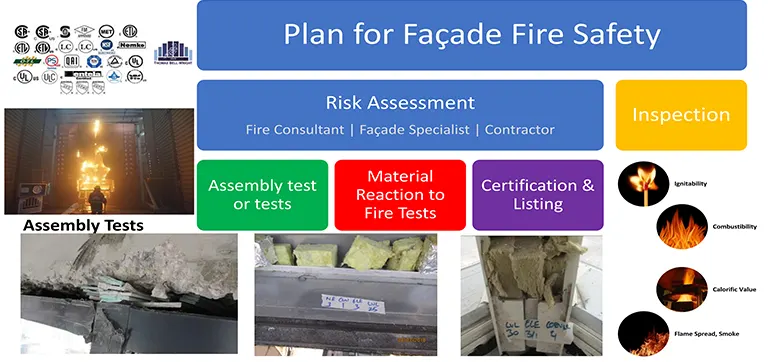

What should be the approach for a solid fire-safe design considering the materials, design and technologies?

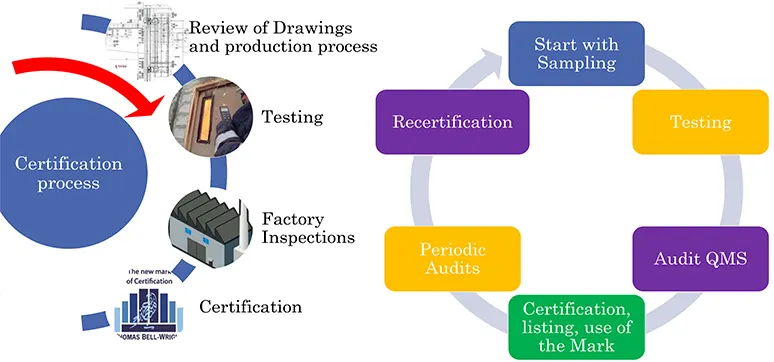

This reply assumes that by ‘solid’ you mean an approach that has a very high degree of assurance. In more than one jurisdiction in the world, the four-step approach is being followed. The same is best explained in the image as well.

The key elements that will ensure a fire-safe building envelope are summarised in the image.

1. Materials: The reaction to fire properties will always add up to a system property. Ignitability, combustibility, calorific value, and flame & smoke spread need to be assessed.

2. Assurance of supply: For such risky materials that are needed; assurance should be undertaken using certification & listing which offers traceability at the construction site

3. The risks of the design of the building envelope need to be assessed by a specialist who will need to conduct or will use large-scale fire propagation evidence to assess the fire risks

4. And then when the designs are firmed up an eligible and liable inspection body needs to ensure what is assessed is what is getting installed!

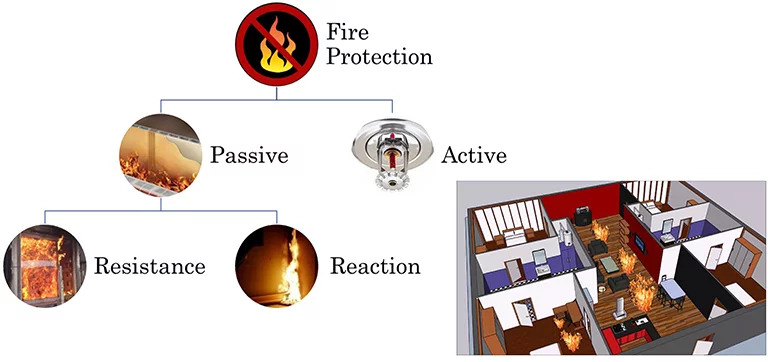

What are the active and Passive fire protection systems/measures used in projects?

Active Fire Protection & Passive Fire Protection as described in Figure 1. Any product or system that activates when there is a fire gets clubbed under Active Fire protection. All sensing device, and reactionary system which controls, contains, or announces a fire get clubbed under this. Passive solutions use their inherent properties to inhibit the growth of fire as well as suffocate and contain it within a created compartment. Everything which can be called internal or external finishing material where a fire grows along as well as systems and products like doors, partition walls, roofs, joints across edges and through penetrations: all add up to be called passive fire protection measures. The key implementation of what is described as passive fire protection is containment or compartmentation of fire. The same is also described as resistance to fire.

What are the standard fire tests carried out to understand the behaviour of fire on the façade and fenestration systems?

These are mainly reactions to fire tests sensing and quantifying ignition, combustibility, calorific values, flame spread, etc. Best clubbed in by the European classification system defined in EN 13501-1. Along with understanding the behaviour of materials, large-scale mock-up fire tests like BS 8414 or NFPA 295 or FM 4881 or ISO 13785-2, or similar are a must to understand how the materials actually interact with each other in a specific final combination of the designs which will be installed.

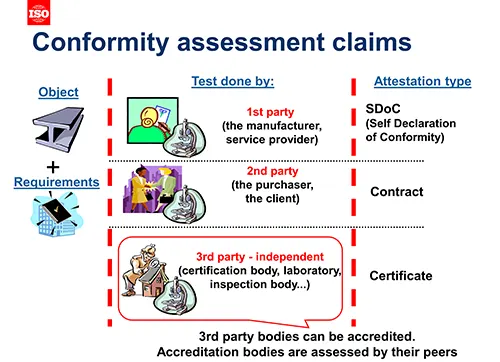

How do you ensure that the products recommended/used on the façades/ fenestrations are tested for resistance to fire?

The most critical part is *NOT* how they are tested, but how they are assured. A test report could be of any sample from anywhere. It could even be fake or forged. The *ONLY* way to get assurance is to rely on a third-party certification mechanism which has a live listing directory with a verifiable certificate number that is checkable at the construction site where the material reaches before installation. Without this traceability which often also provides the limitations of how the material needs to be used to maintain the assurance is absolutely critical. Without it, in my opinion, anyone relying on test reports for assurance is as good as buying from a general marketplace on the internet from an assurance point of view. Once materials come and get installed, there is no return policy!!

Please brief on the requirements regarding glazed façades, especially in high-rise buildings

The starting point to answer this question is the occupancy type of the building which has a glass façade. The type of building (mall/ school/ hospital/ residential tower/ office complex, etc.) is what dictates the readiness of the people whose lives in would be in danger in case of a fire and what else might be at risk of the fire. These are among the several key factors that form the basis of the fire-safety strategy or plan. They help formulate building regulations or guideline documents (Building codes) which are used in more evolved regions in the world.

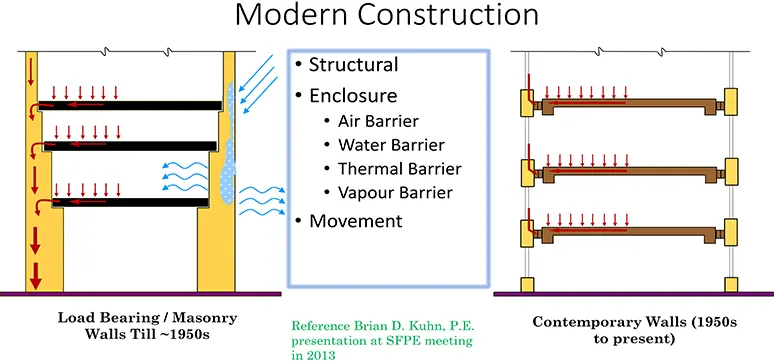

Glass façades have replaced what used to be traditional load-bearing walls more than 50 years ago. They used to undertake several functions as in Figure 4 here. The taller the building gets, the more sophisticated and engineered these solutions become. These functions are often undertaken by several components.

The key fire-safety strategy (of passive fire protection) is implemented by compartmentalizing a fire within the place where it originates. When the building has a glass façade, the most important consideration in ensuring fire-safety is compartmentation. This has to be mainly realized at the floor-to-wall joint (spandrel section) to ensure that the fire can be contained within the floor and does not break into the floors above or below.

Fire propagation across the fascia of a pure glass façade is only a matter of concern when there are other elements across the glass façade that could carry a flame or a fire. In certain occupancy types, the glass façade also needs to act as the fire containment wall and here these are a fire-rated glazing system. We know that the permutations and combinations of raw materials or components that build up a glass façade can be really large. So it becomes critical that assurance mechanisms of the supply of raw materials and components as well as the workmanship of installers are very stringent!

How do we reduce the risk of fire spreading in façades?

Accredited assurance mechanisms that have a link to liability and traceability. AS and example critical materials used for the system should have a certification number that can be traced on the certification directory. Like www.tbewcert.com which lists hundreds of façade system designs which have complied with large-scale tests. Along with the listed systems, inspections to check the correct installation and traceable material are needed to assure. If we don’t do this; it is like sending your 4-year-old alone in a taxi in a city in India; you have some assurance; but do you?