With the increased number of instances of fire on cladding around the world, just about everyone in the construction industry wants to talk about “Fire Testing”. Testing and test reports have been used for decades across industries to showcase capability of organisations to produce superior products and materials. This article aims to add clarity of vocabulary and implications of the tools used to demonstrate the properties of materials used to create fire safe façade systems.

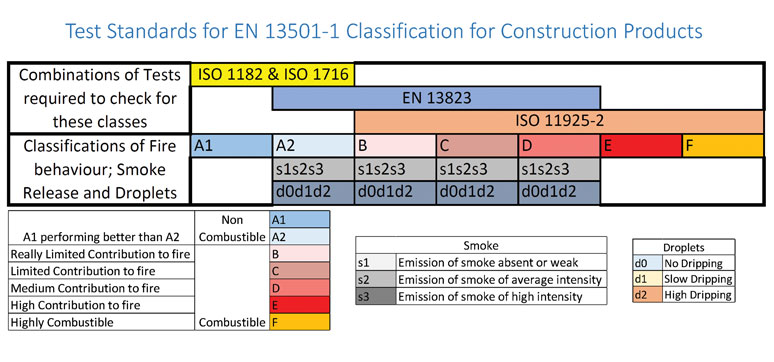

A test report is snapshot of the behaviour of specific properties of a given “sample” of material that may have been produced only for the purpose of testing. There are several properties that explain the reaction to fire and when “samples” are tested for these specific properties we get specific “test reports”. Typical properties that are important to façade engineers designing fire safe façades are: the temperature at which a material can catch fire (known as Ignitability); the amount of heat (energy) released when material burns or combusts (known as calorific value or heat of combustion); rate at which the flame travels across the surface of the material once it catches fire (known as flame spread) and physical reactions to fire (like smoke and droplets released). See Figure 1 to see a table used in Europe to quantify the reaction to fire behaviour of (façade) materials.

A valid and usable test report must capture the following:

- Accreditation or authorisation of the lab for conducting the test. Bodies like National Accreditation Board for Testing and Calibration Laboratories (NABL) or United Kingdom Accreditation Service (UKAS) follow a uniform method (as per ISO 17025) to evaluate the capabilities of the lab to test and report given properties. Without this traceability, a test report is equal to unsigned handwritten note on paper saying, “I promise to pay the bearer a sum of two thousand rupees”.

- State, condition and origin (or traceability) of the sample used to conduct the test. This is the only part of a test report that “may be” used to provide a link with any other Façade material that is claimed to perform as per the tested sample. If this information is not available, it is possible that the sample given for testing has been engineered (or produced in another location) to lead to specific/ better results when tested.

- Date of the test report and the version of the test standard against which the test has been performed. Materials tested long ago or as per older version of the test methods can be misleading. It is equal to complying to and older law which has not been amended. Readers of test reports should not confuse the usage of the term “validity of test report” to link with the manufacturing date of the material supplied. The validity in months or years mentioned in test reports is only done keeping in mind a revision cycle of the test method. Hence, a report issued in March 2016 which could be valid for three years does not mean that all the material manufactured till March 2019 will be the same as tested. This only means that the test standard used to conduct the test, say ISO 1716:2018 (Reaction to fire tests for products — determination of the gross heat of combustion (calorific value)) might get revised by 2021.

So how does the contractor or buyer of any raw façade material get the assurance that the material that will be supplied will behave as the sample produced for the test report.

This test report may have been submitted as part of the qualification submittal or be part of claim on a product brochure. There are only two valid means used to get this confidence. This first relies heavily on mutual trust between seller and buyer. Here the seller (sometimes) gives a copy of a test report (which may or may not have the above three points) and submits a proof that the manufacturing facility follows some Quality Management System (like and ISO 9001). If buying products and materials that do not deal with the life safety of people and the potential loss is an amount is bearable by the buyer; this method can be used. The pitfalls in this process are many and the buyer needs to have a keen eye and depth of knowledge.

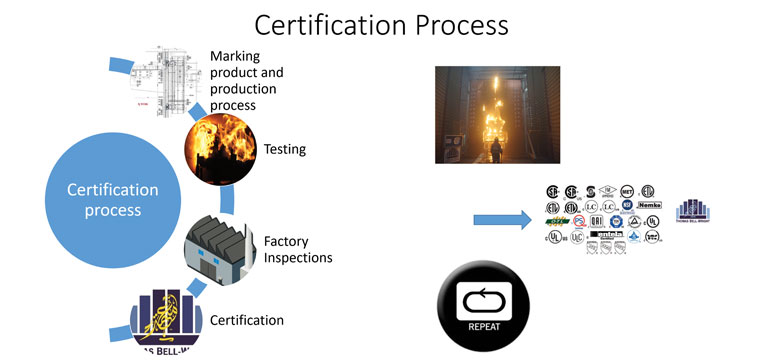

The second method is fairly airtight though not fool proof. Ignorance to link the pieces of information incorrectly can bring the buyer at par with the earlier method described. This method known as certification and listing relies on a third party organisation (certification bodies or CBs) whose job is to methodically offer tools to quantify this trust. These CBs need to have an accreditation as per ISO 17065 to be in a position to offer these services of certification and listing. To establish the much needed trust, they follow a fourstep process shown in Figure 2.

Step 1. A qualified staff member witnesses the production process of the product/material that will be tested. The process and raw materials are mapped and the sample is marked for traceability.

Step 2. The marked samples are tested to produce a test report complying with the three points pointed out earlier.

Step 3. Post successful tests, the CB starts to regularly audit the quality control processes at the given manufacturing location. This is done to ensure that the products shipped with the traceability of certification (certification mark/unique ID/number) are manufactured in the same way as the witnessed samples were made.

Step 4. After the success, the CB lists the name and identification of the product/ material packing along with manufacturing location and details of the fire tests the material is complying with on their public domain website. This acts as a buyer’s guide and an important tool for buyers to verify the claims in product brochures or price proposals.

Certification and listing of the reaction to fire properties of façade materials provide the vital foundation for designing the much needed fire safety in the building envelope. This helps façade engineers choose the correct raw materials for their designs.

Armed with this knowledge and assurance or repeatability of reaction to fire properties; façade engineers use their skills to carefully mastermind a system that is able to provide the weather-tightness and insulation as needed. But they also envision what is the total volume of the material with the lowest ignition temperature. And hence understand if this material does catch fire what could be the total (combustion) energy released and how that would affect the adjacent materials. This helps them assess the risk of a chain reaction cladding fire.

This can only be an approximation and hence a large scale mock-up fire test is performed to validate the design theory. Tests like the NFPA 285 or the BS 8414 are used to see a practical behaviour of such designs in case of a fire scenario. See Figure 3.

With the assurance of repeatability of the supply of tested and listed façade materials and validation of the fire safe façade design, the façade subcontractor is challenged to install the repetitive system all over the building and ensuring no errors are introduced that may be amplified due to the repetitive installation across the building. It is a common practice to have qualified independent third party inspectors oversee the installation process by comparing with the drawings of mock-up, which has been tested as per the large scale fire tests.

In several evolved jurisdictions across the United States, Europe and now in the UAE, these are mandatory legal requirements.