With the inception of the latest technologies and different materials along with attractive finishes, the architectural hardware for the doors and windows industry in India is witnessing a new wind of change.

Technical Head, McCoy 8M

The presence of several international and domestic hardware products in the market provides a variety of choices for consumers. One can get good quality, functional hardware at a reasonable price.

However, a market pervaded with fierce competition between brands, coupled with a lack of information/ awareness on prices, authenticity, tests, standardization, etc., can create confusion while choosing the right hardware for your project.

The right choice of architectural hardware is one of the key elements to the success of a project. Most of us are not very familiar with the significance and properties of architectural hardware used.

WFM Media discussed the market trends, latest technologies, and materials available in the market, various tests and certifications done to ensure quality and longevity, standards for hardware, etc with many industry experts. The focus of this article is to help you to choose the right kind of hardware. Read on…

Founder, PEGO Hardware

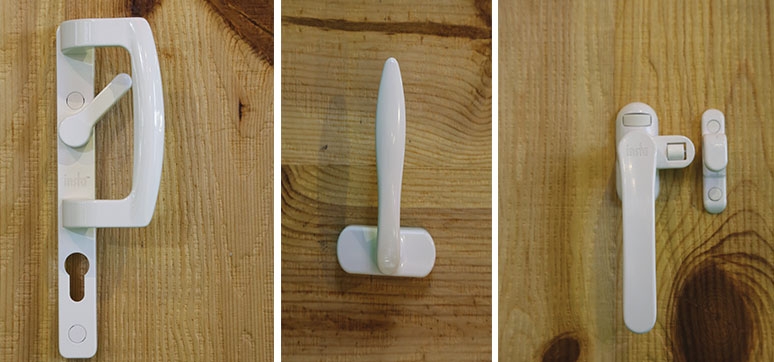

While choosing hardware, function, durability, design, and quality should be considered along with cost. One can get good quality, functional hardware at a reasonable price. But to expect the best of everything at a very low price is impossible. At the same time, the best-quality hardware may also fail if it is not compatible with the profile. Compatible hardware is the key to better-performing windows/doors. Choosing the right hardware is about ensuring that all components meet stringent standards, and work together effortlessly.

Hardware should be chosen carefully for its reliability, technical performance, aesthetic appeal, and value for money. We spoke to a few experts on criteria for the selection of architectural hardware for façades and fenestrations. Here are some basic tips from the experts on what to look for while shopping for hardware.

Raju Banerjee, Technical Head, McCoy 8M observes that selecting the right hardware for doors and windows is imperative. There are many criteria that need to be considered when we are selecting quality hardware. According to Banerjee, in the case of load-carrying hardware, like friction hinges, rollers, etc., we must ensure that the hardware selected should be more than capable of carrying the required load.

Director, Glorious Products India Pvt

Ltd. (Insta Hardware)

For this, we calculate the weight of the sash. Other things that need to be considered are ‘resistance to weather conditions like resistance to different types of corrosion, weather, dust sealing capability, etc. In service, longevity factors like ‘Cycles of Operation’ has to be considered to avoid un-due deterioration. Lastly, aesthetics, easy installation, maintainability, ease of availability, and cost are some other factors that need to be considered”, elaborates Banerjee.

Application, utility, and geographical location are key elements in deciding the hardware for any door and windows need, says Karan Shah, Founder, PEGO Hardware.

Hardware selection depends upon the typology of the doors and windows, says Raman Dhiman, Director, Glorious Products India Pvt Ltd. (Insta Hardware). Once the typology is decided then points come for the look and feel of the hardware and security and locking mechanism. “I would advise if you are electing hardware, then security and durability will be the priority”, he adds.

Mohammed Shaiban, Sales Director – South Asian region, Bangalore, India, Consort Architectural Hardwareadds that the type of building matters when we specify our needs while selecting hardware. “Firstly, to find out which type of building the specification is for, for example, is it a commercial project or residential project?”, he says. Ironmongery needs to be certified and tested within fenestrations and it needs to be compatible i.e. If it is a highly used area, then this must be taken into consideration, adds Shaiban. It is also important to ensure compliance when it comes to fire codes, making sure hardware is certified and tested.

According to Ar. Priyanka Arjun, Principal Architect, Priyanka Arjun and Associates, the three most important criteria for the selection of Architectural hardware for façades and fenestrations are:

• Aesthetics and requirements of façade design

• Window width, height, and weight

• Surroundings and environment conditions – wind speed plays an important role

R Satyapal Singh, Sr. Design Engineer, King Hardware India Pvt.Ltd., defines the key parameters to look for while selecting hardware. They are safety, bearing capacity, appearance, installation convenience, and cost. There are a few other criteria too. “We would give our customer, the project solution drawing, structure & product calculation report as well as the customized product design for reference,” adds Singh.

LATEST TRENDS IN HARDWARE FOR DOORS, WINDOWS & FAÇADES

System companies and fabricators and end-users are increasingly on the lookout for innovative and out-of-the-box, aesthetically designed, window and door systems that are well-engineered for performance. what are the latest trends in hardware for doors, windows, and façades? Let’s hear from experts.

For any industry, it is very critical to evolve with time and innovate before becoming obsolete. Everyone wants to change and hence even the shelf life of hardware products has reduced with time. “We at PEGO, take great pride in taking the leap and constantly coming up with innovative products to address the industry needs. Currently, the trend seems to be moving towards minimal, straight-line hardware. The concept of one family hardware design is also very important and has gained more relevance now than ever before,” observes Shah from PEGO Hardware.

The end users today are better informed and they are looking at hardware that will be intuitive and innovative, and be different from the run-of-the-mill, ordinarily used hardware for casement or sliding doors and windows, says Banerjee from McCoy 8M. Different types of doors and windows, like slide and fold, tilt and turn, tilt and slide, slide and pivot doors, and vertical sliding windows are being opted for more often.

Sr.Design Engineer,

King Hardware India Pvt. Ltd.

We need to classify the market into two I.e. retail and project. “If you ask me, there are not many new trends in the project segment. But if ask about retail, then preference changed to innovative design, aesthetic and automation,” says Dhiman. The basic functionality of the hardware is the smooth working of any door, window, or any opening in the façade. So with innovation, the design part is only changed but the functionality is the same.

THE ‘SLIM-LINE CONCEPT’ AND BEYOND

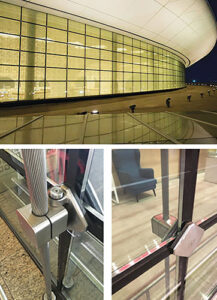

The “slim-line concept” is the trend today, where the outlook of the openings, and mullion profiles appear as a thin line on the large size of the glazed openings. Is this a call for the complete revision of conventional hardware designs and concepts and also a call for finding proper solutions?

Gone are the days when bulky meant good & strong. It has happened in various industries where minimal approaches are being preferred, says Karan Shah. “I do not think a complete overhaul of hardware is required for such designs. It only requires an out-of-the-box thinking process coupled with strong system awareness & application. Primary application and the need remains the same & one needs to operate within that framework,” he adds. “At PEGO we have been working very hard to evolve and have managed to bring in products to cater to these new fenestration requirements,” said Shah.

According to Banerjee, while many customers opt for “Slim-line” profiles, and these are catching up, yet, conventional profiles are also being used. “I feel that the slim profiles would still take some more time to get absorbed for mass scale usage, however, we would not be very wrong in saying that now is the proper time for revising the conventional hardware designs and also finding suitable solutions for the slim profiles,” observes Banerjee. The reason for this is, he adds, though slim profiles would eventually gain momentum, yet, the conventional profiles would continue to be used, being tried, tested, and proven design, and the same holds for the associated hardware.

TESTS & TEST METHODS FOR DECIDING THE QUALITY OF HARDWARE USED IN WINDOWS & DOORS, & FAÇADES

Needless to say that all the hardware is to be tested for corrosion resistance, longevity, etc. so that the end-user gets total satisfaction from using the same, says Banerjee.

The tests and test methods widely depend on the type of hardware product as they will have specific tests to ensure their durability, corrosion resistance, and security among other things. There will be different grading levels of EN standards for each type of product. This means, that some products which have been tested to EN standards could easily not perform as well as other products, notes Shaiban.

According to Karan Shah, Key tests are done to check the following aspects which are very critical:

• Product life cycle testing

• Base metal composition

• Powder coating thickness

“We at PEGO are having in-house testing machines to test the product and we invite customers to our facility to witness the same. The transparency helps in winning the trust of clients and gives them confidence,” adds Shah. “Further we have created animated video manuals for a lot of our offerings like sliding folding, tilt & slide, lift & slide so that it is easier for customers to manufacture these systems. Further, all our offerings are segregated into smaller system-wise templates to provide focused information to window manufacturers,” he elaborates.

Ar. Priyanka Arjun too agrees that it is important to conduct durability tests and performance tests for all hardware products.

Singh from Kinlong Hardware elaborates that different test methods are done for different hardware even if they are in the same façade or door & window system. “For example, for fittings in the curtain wall system, we follow GB-T 37266-2018, and we follow JGT 201-2007 &JG T 200-2007 for cable fittings. For doors & windows, we follow standards for different accessories of door & window systems.

Various tests are done to check the noise, air infiltration, and water penetration in curtain walls adds Singh. As per the China standard, GB/T15227-2007 is done for the curtain walls designed to match air tightness, water tightness, and pressure resistance points out Singh.

“Normally Kinlong follows China standards in the façades(JGJ102-2003 Technical Code for Glass Curtain Wall) and Door & Window (JG-T 326-2011, JG∕T 125-2017, JG-T 126-2017, JG-T 127- 2017, etc) system,” he explains.

Tests are done to check the noise, air infiltration, and water penetration on curtain walls and fenestration too. Ironmongery will not require testing. However, for door seals and door sets, there are specific tests to test the sealing, acoustics, and weather testing of those door sets. According to Shaiban, different couturiers will test acoustics in different ways for different sounds/ noises. Singh says, as per the China standard GB/T15227-2007 the hardware designing to match air tightness, water tightness, and pressure resistance.

CHECKING STANDARDS & CERTIFICATIONS WHILE BUYING HARDWARE

The standards and certifications widely depend on the type of product, says Shaiban. For example, door sets can be CE marked and ironmongery is tested by individual components such as British and European testing standards. There are many more testing standards available, however, some of the core ones are listed below:

• BS EN 1906 is the standard requirements and testing methods covering lever handles and knob furniture according to British/European standards.

• BS EN 12209 is the standard requirements and testing methods covering locks, latches, and locking plates according to British/European standards

• BS EN 1935 is the standard requirements and testing methods covering single-axis hinges according to British/ European standards.

• BS EN 1154 is the standard requirements and testing methods covering controlled door closing devices according to British/European standards

• BS EN 1125 is the standard requirements and testing methods covering panic exit devices operated by a horizontal bar according to British/European standards. Experience relating to escape from buildings and general safety has made it desirable that doors at final exits in public buildings, places of entertainment, shops, etc., should be fitted with panic devices operated by a horizontal bar. The emphasis for products covered by this standard is on safe exit rather than security.

PEGO Hardware

Priyanka Arjun looks for AAMA, European standards, and BIS standards while selecting hardware for her projects. Singh goes for CE for fittings for both façade and door & window systems; IFT for door & windows; and other local standards and certificates especially as per project requirements.

Lack of standardization of window and door systems considering the design approach is one of the major challenges faced by the hardware industry. For increasing the acceptability of hardware, it needs to be tested for weather resistance, longevity, etc., before being used.

In the Western world, profiles are designed while keeping the hardware products in mind, says Shah from PEGO. “We have observed that in India a lot of times profiles are designed and then hardware solutions are searched. This creates an issue in finding the right solution and many a time, hardware is a compromised solution. This impacts the strength of the window/door system itself. It also results in a struggle with a lot of customization in hardware which unnecessarily increases the cost resulting in the higher cost of the window for the buyer as well,” adds Shah. He explains further – “many have learned it the hard way and hence we have seen the beginning of a change in this practice now. By taking hardware companies along at the designing stage itself, system/profile companies are saving themselves a lot of time, effort, resources & cost. This has got them a better solution which is much steadier & durable & cost-efficient,” observes Shah.

Dhiman and Banerjee too agree that the lack of standardization in the design of window and door systems is one of the major challenges. “The issue stems from the hitherto absence of existence of a proper standard related to the design parameters and recommendations. However, now we have organizations like UWDMA working to incorporate world-class standards, and soon we shall be able to see a good amount of standardization which will, in turn, improve the overall situation,” Banerjee is hopeful. “If you talk about the solution, practically it is impossible without standardization,” states Dhiman.

There is a limited amount of testing and certification of architectural hardware happening today. However, with efforts from organizations like UWDMA, BIS, etc., new standards are being worked upon and are expected to be implemented in the near future, adds Banerjee. Post this, we expect to see a set of tested and certified hardware being accepted by the industry.

KEY SAFETY PARAMETERS

Most people always think that the fire safety of the façade system is the most crucial element – but durability testing is just as important, points out Shaiban. For instance, if a donor doesn’t shut properly then a fire door won’t do its job, meaning it has failed. It’s also important to ensure technical personnel who are specifying the ironmongery are the most qualified and knowledgeable. We have a dedicated team at Consort who can help with your specification requirements.

According to Ar. Priyanka Arjun, test reports, warranty, availability, and service level are the 4 most important aspects one should consider while selecting hardware.

Singh adds that one must consider safety, bearing capacity, appearance, installation convenience, and cost factors are the major parameters to consider while choosing hardware.

IS THE IMPORTED HARDWARE COMPATIBLE?

Shaiban agrees that imported hardware is compatible in their case. But he cannot answer for other suppliers. It really does depend on the people importing the goods. “We supply to many coastal regions around the world where our ironmongery has been fit for purpose. Corrosion-resistant ironmongery should be taken into consideration. For example, Marine-grade for the coast. Lower-grade products would not be suitable for humidity and salt near the sea. Also, salt from people’s hands and corrosive materials from acidic cleaning products would pose a problem in the long term.

According to Singh, the imported hardware is suitable for Indian weather and geographical condition as we have the accessories by using austenitic SS material such as 2205/CD3MN for coastal areas and special weatherproof coating for selective material.

According to Karan Shah of PEGO Hardware, the major innovations in design, materials, & technology implications for architectural hardware are –

1. Moving to minimal designs

2. Higher weight capacity rollers, hinges & friction stays to cater to larger openings

SOURCING HARDWARE: COSTQUALITY RATIO

Do you find it difficult to get quality hardware for a reasonable price in the Indian market?

The products supplied by the suppliers are reasonable for the cost-to-quality ratio, says Shaiban. “It also depends on what you deem reasonable. There will always be alternative options in the market that are budget-friendly, however, the product life cycle will be reflective of this and will require quicker replacement, and therefore, in the long-term, they aren’t deemed good considering ‘value for money.

Architect Priyanka too areas on the various options available in the market – both imported and made in India. For quality products, we are always considering factors including safety, comprehensive with the bearing capacity level, appearance level, cost level, etc. So we are flexible to focus on different aspects as per the demands in the Indian market and get the quality hardware accordingly, adds Singh.

AUTOMATION IN APPLICATIONS

Automation in applications like digital access locking handles automated opening-closing mechanisms, especially those for skylights, windows, chain operator control mechanisms for top-hung windows, motorized roll-up sun shading screens, etc., are becoming popular and are catching up in Indian markets.

According to Karan Shah, automation & smart windows are the future. Like any other industry, it would take time to incorporate technology into the hardware and make it foolproof solutions, but a lot of initiatives have been taken all over the world. “The biggest challenge in this would be after sales service as it is a new subject and that will have to be dealt with care. The price of these products would slowly normalize with scale and more trained human resources to tackle the after-sale service,” adds Shah.

Automation is the new fashion, but the problem is the availability of these systems and price. says Dhiman. “My honest opinion is that automatic systems are only suitable for the commercial entrance door. Rather than it fits into other door windows,” he adds.

Banerjee too observes that automated doors and windows systems like digital access systems, automated opening/ closing systems, automated window opening, and closing systems integrated with building management systems for natural ventilation as well as smoke evacuation are the trends and have of late caught up. Many commercial and corporate buildings are opting for such systems for safety against intruders, fire hazards, or just plain periodic ventilation to save on electricity costs. However, since these systems include a lot of sophisticated components, the price is quite prohibitive, as of date. However, it is expected that with more numbers coming into use, the pricing could be controlled more effectively in the future.

IMPACT OF COVID ON HARDWARE USAGE

Do you think that the demand for automatic doors and windows has increased especially in hygiene-sensitive areas during this pandemic phase? Computerized building control systems have a lot of scope considering safety and security.

COVID has accelerated the demand for automation. The COVID protocols are here to stay means the demand for smart windows will remain. Further certain areas where accessibility & operation of windows are difficult, smart windows will only make it easier, says Karan Shah.

Since natural ventilation is a key benefit derived from installing automated window and door opening systems, it is definitely going to find a good use for ventilating hygiene-sensitive areas, especially during the pandemic phase, like in hospitals, observes Banerjee. Such systems, apart from providing better safety and security, would also be able to afford ventilation, and that too, without a lot of human intervention. So, yes, the demand is certainly going to increase for automated systems and smart doors and windows. However, as mentioned before, the pricing also needs to be rationalized for all this to happen, adds Banerjee.

FUTURE POTENTIAL FOR THE ARCHITECTURAL HARDWARE PRODUCTS

With more focus on infrastructure, the fenestration industry is bound to grow. The next big growth vehicles would be tier 2 & tier 3 cities. Rising base metal costs would make it necessary to innovate on the hardware composition to counter that and this is where technology up-gradation in manufacturing & client servicing will play a big role, points out Karan Shah.

The future potential of architectural hardware products is quite bright, notes Banerjee, I would say, as awareness spreads amongst users, we will see the need for more innovatively designed doors and windows like slide and pivot, bi-fold doors, tilt & turn and tilt & slide doors. New materials would be brought in to improve hardware functionality and aesthetics, keeping overall costs in mind. With new materials would come along new methods and technology. All this would run parallelly with the existing hardware, thus, expanding the market, Banerjee is highly optimistic.

CONCLUSION

Hardware constitutes a meagre 1-3 per cent of the building cost. However, over a period of time, maximum issues arise due to malfunctioning hardware, which can result in accidents and revenue loss. The right kind of hardware must be chosen to protect the building from climatic effects and also for the safety and aesthetics of the building. The selection should be based on its quality, performance, and longevity. Other key factors to consider are compatibility with the profile, corrosion resistance, and cycle performance backed by proper testing and certification. Hardware is also moving towards digitalization. Automation, monitoring, remote accesses, and management are the latest requirements driving innovation. Advancements in research and technology have enabled improved designs and given precision to products with quality and sustenance.