Architectural Hardware/ Ironmongery

Architectural Hardware / Ironmongery

Architectural hardware plays a key part in all buildings and in everyone’s day-to-day lives, so much more than is realised. Incorporating look, feel, functionality, security, performance, fire life safety, accessibility, acoustics, weather protection, and energy efficiency to name but a few. It is essential that your building is specified correctly by an industry expert, and that the products comply with the relevant codes and standards and are fit for purpose.

Understanding Product Standards

There are currently two prevailing sets of standards related to door hardware / ironmongery that form the basis of the majority of project specifications. These are British / European standards, identified with the BSEN and CE prefixes and North American standards identified as ANSI/BHMA.

Architectural Hardware Product Standards: BSEN & ANSI / BHMA

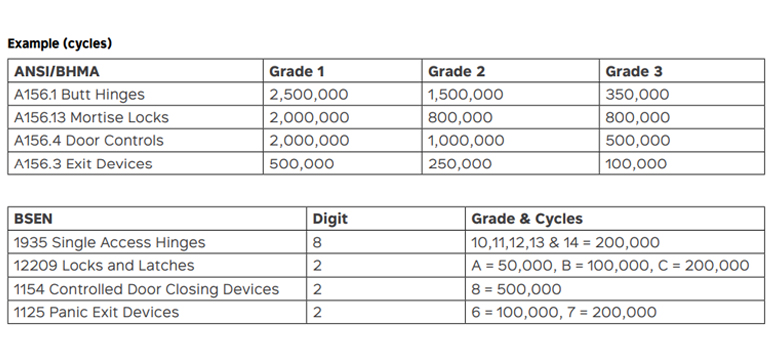

These standards indicate performance levels on each product, carrying out stringent testing such as operational, cycle, strength, security, test apparatus, and test methods. All procedures described within the standards are performed under laboratory conditions. ANSI/BHMA A156 series of standards, normally consists of a 3 Grade system, with Grade 1 representing the highest level of performance, whilst BSEN use a digit coding system (six or more-digit classification) with each digit referring to a particular feature of the product measured against the standard’s performance requirements. Certified products are guaranteed to meet the criteria called for by their standards.

Fire Life Safety

What is a fire door?

A fire-rated door assembly is specially constructed to slow or prevent the spread of fire and smoke for a specified time period and provide a safe and protected escape route for occupants evacuating a building. Simply put, the purpose for fire doors is to save lives and limit the spread of fire.

Fire Testing – EN1634-1 and UL10C

Certified by Warrington Fire (BSEN) and Underwriters Laboratories UL (ANSI Accredited), are third-party certification schemes that assure performance, quality, reliability, and traceability of products and systems. Both have online registers that list all certified products and make sure continuation of testing as well as initial testing. By doing this it gives peace of mind that products are undergoing continued checks as well as initial tests. There are many other certification schemes in the market, but these tend to be the most recognised.

EN1634-1 and UL10C fire tests expose the door assembly to a controlled fire exposure, set to achieve regulated temperatures throughout a specified time period. UL 10C uses a positive pressure test where the neutral pressure plane is located forty inches above the floor to replicate the conditions of a real fire and is followed by the application of a standard fire hose stream more accurately. EN1634-1, it is important to remember that the passing of the fire test EN1634-1 is not the sole criteria and safety measure to consider when selecting hardware for a fire door. It may pass a fire test in isolation but if it has not passed the remaining EN requirements the door will not perform the rest of the functions required during the lifecycle of the building to actually be operable in the case of fire directly causing loss of life regardless of the fact it passed a fire test in a laboratory.

Differences & Similarities Across Codes and Standards

As an example, North American codes and standards stipulate that fire door assemblies must be closed and latched in the event of a fire, however BS legislation fire door assemblies are acceptable without having an active latch bolt but must have a self-closing device. UK legislation demands mandatory signage on every fire-rated door, regardless of application.

Both standards agree that fire doors must self close and in the case of doors that are required to be held open, they must be linked to the fire alarm interface and release to close in the event of a fire.

Fire-rated openings on escape routes must open in the direction of egress to enable evacuation of the building. As the codes and standards and their required applications differ, it is most important that the Architectural hardware specifier / supplier has a strong knowledge and understanding of the relevant building codes, fire codes , and referenced standards. Either can be viable by correct specification, and by adhering to one fire life safety code. Mixing codes and standards is a potential recipe for disaster and should be avoided at all costs.

Common Codes and Standards Used Across North America

- The Life Safety Code (NFPA101)

- International Building Code (IBC)

- Standard for Fire Doors and Other Opening Protectives (NFPA80)

- International Fire Code (IFC)

- Accessible and Useable Buildings and Facilities (ICC A117.1)

- Standards for Accessible Design (ADA)

- American National Standards Institute (ANSI)

- Builders Hardware Manufacturers Association (BHMA)

Common Codes and Standards Used Across Europe and the UK

- Fire safety in the design, management and use of buildings (BS 9999)

- Fire safety in the design, management and use of residential buildings (BS 9991)

- Parts 20 & 22 – Building,

- Regulations 2000 – Fire Safety – Part B (BS476)

- CEN Committee European de Normalisation (European Committee for Standardisation) (CEN)

- British Standards Institution (BSI),

- Design of Buildings and Their Approaches to Meet the Needs of Disabled People (BS8300)

It is so important to make sure that your hardware functions and serves the correct purpose across a building to make sure that the safety of the building and people within it is not compromised. The correct hardware is another element in ensuring the safety and correct functionality of a building and access points. Consort is always here to discuss certifications and requirements on a project and can advise you on how best to protect your building.