The façade of a building is an architectural feature with functionality. Along with the function of keeping the weather and environment out, it also fulfils an important need of a building, that is to differentiate itself from others. It is rare to find a façade designer/contractor wanting to create a building envelope exactly like another one. And if it is being re-created; you can never find the exact same combination of materials and workmanship!

This need to differentiate combined with the driver of ‘the economies of scale’ challenges the architects, engineers and businesses in almost every tall building which is susceptible to a façade fire. The challenge is to minimise the cost and time to build it and ensure it complies with all the expectations of performance. Let us dig deeper to view the understanding that has developed so far to ensure fire safe façades and why so many people around the world continue to get it wrong.

Repeatability: A myth or reality

A key source of fulfilment is when our expectations are met. Expectations of what a building (or a product we buy) looks like or performs like. These expectations are based on parameters claimed and defined. All the products we use or see around us are assumed to be exactly the same on several parameters. Mobile phones to cars; chocolates to burgers; glass to gaskets; insulation to brackets. looks, taste, performance: so many parameters!

Now, bringing about repeatability is not always a straightforward process. With constantly changing supply chains of raw materials and changing people dynamics, quality professionals struggle to implement processes that ensure repeatability. As the focus on achieving fire safety increases, it is important to know and understand how this repeatability is realised. And most specifically, understand how repeatability of performance is achieved when creating ‘building envelopes’ which need to be unique in the way they look every time. What are the evolving tools and procedures to realise this repeatability?

Repeatability Of Fire Safety

The vagaries of the weather endured by a building create the need for the inside of a building to be separated from the outside. Heat/cold, wind, water, sound and the list can go on. Varying levels of performance about the ability of a building envelope to effectively separate the ‘outside’ and the ‘inside’ have been accepted around the world. But with fire risks creeping into the equation, matters related to ‘repeatability of fire safety have become very important. Performance levels once linked with ‘comfort’, ‘energy efficiency’ have paled against ‘life safety, ‘property protection’ and even ‘brand value’. So how do we design and implement a building envelope that will not end up in a fire accident? Here are the key steps used to create a solution that can demonstrate repeat performance on fire safety.

Steps for Fire-Safe Facades

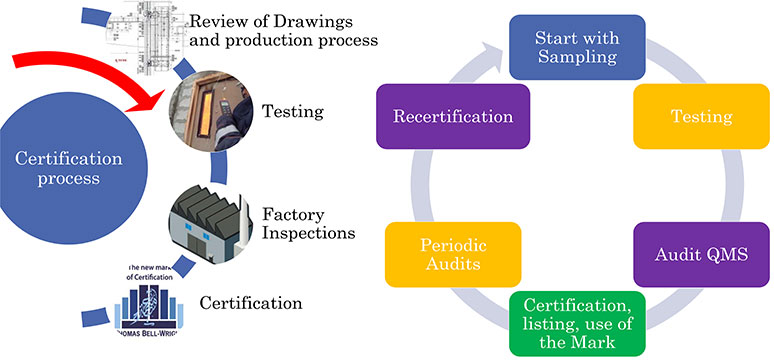

The key to the repeatability of any designed system is to ensure that the building blocks can demonstrate the repeatability of performance. Image 1 shows the pillars of ensuring Fire Safety is designed and implemented accurately.

Certification and listing

In countries around the world, the tools of surveillance are always visibly stricter for matters related to the safety of human life. You will notice that “medical devices” and “structural integrity of buildings” will get more important as compared to “furniture performance” or “weather insulation in a building”. Image 2 describes a common process for enabling a higher degree of ‘quality assurance’, that is certification and listing. Here an independent third party (different from buyer/ first-party and seller/ second party) is independently involved in a contract to assess and assurance the claimed performance of products being bought or sold (buyer/seller).

There are International Standards of ISO 17025 (general requirements for the competence of testing and calibration laboratories), ISO 17065 (conformity assessment, requirements for bodies certifying products, processes and services) among others have been published and guide on bringing forth parity to the processes followed by these third-party certification bodies. Key common outcomes of these independent certifications and listings are a unique marking or a mark with a traceability code or a number which is carried by all the products assured by a given certification body and a public domain website directory where details are ‘listed’ to enable buyers to distinguish and verify the certified products. Image 3 shows an example.

Design Validation

This is a critical step where the knowledge and experience of façade specialists (designers, contractors, suppliers) should be correctly used to ensure the designed systems can withstand the possible scenarios that could cause a fire incident. Façades used in buildings today have taken over many functions which were originally performed by thick load-bearing walls half a century ago. Ranging from weather-tightness to preventing initiation of fire or growth of fire within or on the exterior surface. And of course, the designs need to ensure the fire should neither ‘move into a building nor‘ move out- of’ the building (on to the façade). To understand how this is prevented, let us start with commonly misunderstood terminology.

Fire Resistance (Fire Rated) Often detailed using the word compartmentalisation: Fire resistance is the ability of a designed product or a system (like a wall or a door) to ensure that the fire if initiated is compartmentalised or contained within a small area and does not spread rapidly outside this containment zone. Often the time between the initiation of a fire (dropping a burning matchstick or a cigarette stub as an example) to the time when major combustible items like sofa or mattress, etc. are burning (creating a temperature of over 1000 °C and pressures of more than 10 Pascal) can be less than 5 minutes (flashover time). So, if you are in a room that is fire rated, then the walls, doors, ducts/ dampers, windows, etc are verified for being able to contain the fire within the room (for a given duration of 1/2/3 hours).

Materials like Aluminium Composite Panels/ACP (4-6 mm) which are made using less than 1 mm of aluminium (

whose melting point ranges from 300 to 600 degrees) can never be ‘fire rated’. This is a common misconception. A wall assembly could carry an ACP and the wall system could be fire-rated, but an ACP alone does not stand a chance to contain a flashover fire. Though usually known to be created using walls, ceilings, etc., in the context of a building envelope there are a few other sections where this becomes important. See Image 4 to view the section between the façade and the slab of a floor which requires such a containment. This containment is brought about using a “perimeter fire barrier” which also needs to allow for building movement. The “perimeter fire barrier” ensures that the fire does not move from the compartment of a room on a given floor to another floor. Also, see image 7 to see how they get tested.

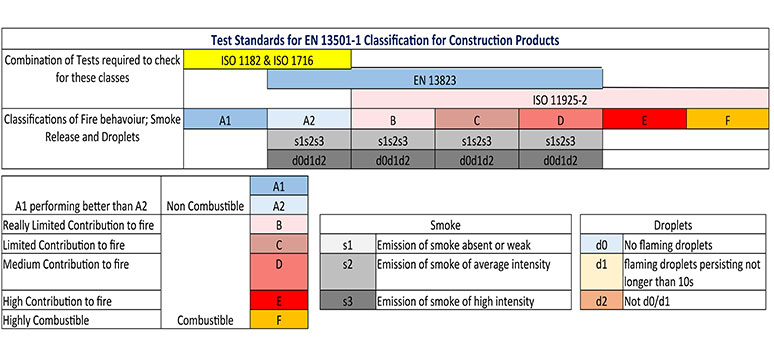

Reaction to Fire How any given material will behave when the environment around it can create a fire or is creating a fire can be defined in many ways. Knowing exactly how building materials behave on these parameters become very helpful for façade designers when considering their use to design a building envelope system. Ignitability is the ability of a material to be ignited (catch fire). Quantified using test methods like ASTM D 1929 (determining ignition temperature of plastics) or BS EN ISO 11925-2(ignitability by direct flame) or EN ISO 1182 (non-combustibility test). The chemical composition of a material dictates the amount of latent energy the material has. Quantified using parameters like Calorific Value and Heat Release Ratio using test methods like BS EN ISO 1716 (gross heat of combustion/calorific value).

The spread of flame, smoke and other behaviour depends on the composition and distribution of potentially flammable ingredients of a material. This is often quantified using tests like the ASTM E84 (surface burning characteristics of building materials), BS EN 13823 (single burning item) and many others. The European Classification Standard EN 13501-1 (fire classification of construction products and building elements. Classification using data from reaction to fire tests) summarises the reaction to fire behaviour very well. Look at Image 5 for more. It is a common mistake to confuse the reaction to fire properties like low Ignitability and call it ‘fire rated’.

Prevention of Fire Propagation Often there are several dozen different materials used to design and bring about a façade. It is also very common that there is a large number of sectional drawings detailing façades design details for buildings. For certain high rise constructions, the number of these drawings could go into hundreds or even more. This is the critical point for the fire safety of a building façade. Using the understanding of ‘reaction to fire’ properties of materials to be used designers and contractors have the last chance to screen specific sections where a higher risk of fire exists. Incorrect combinations of material, thickness, spacing and even air gaps can lead to weak spots capable of creating an uncontrollable fire.

To validate the design and material selection, fire propagation tests are conducted. Here an assembly of a building envelope is mocked up with all materials, components, gaps replicated to represent the worst-case scenario of a given building. Some projects call for several such tests as there would be several potential weak spots. Several different tests methods are used in the world to validate if the fire can grow or move across the building envelope in any direction. Fires can move across materials, in-between airgaps and often in a chain-reaction model where the reaction to fire of one material instigates the reaction to fire of adjacent material.

While most of these tests validate aspects of fire propagation, some tests also evaluate the fire resistance of the elements of a building envelope system that are needed to contain the spread of fire from one compartment to another (like floor to floor). Image 6 shows the Intermediate Scale Multi-Storey Test Apparatus (ISMA) which is used to validate the fire propagation of vertical façades using the NFPA 285 (standard fire test method for evaluation of fire propagation characteristics of the exterior – Non-load-bearing wall) test and Image 7 shows the same apparatus is used to conduct the ASTM E2307 (standard test method for determining the fire resistance of perimeter fire barrier systems using intermediate-scale, multi-story test apparatus) test to validate the ‘fire resistance properties of perimeter fire barriers’ using a mock-up test. Image 8 shows the fire propagation test from the United Kingdom, the BS 8414 (intended to give an indication of fire spread across or within an external cladding system) test.

Assurance Of Installation

Building façades often comprise repetitive designed elements that go up the floor on the floor. For tall buildings, a small error simply magnifies. Specialist inspectors are called to verify comprehensive details of façades. They are capable not only to read and understanding drawings but also, they are able to verifying the supplied materials to have evidence of certification and listing (described in Image 3). These installation inspections are extremely critical and hence the need to hire specialist inspectors who are objective and experienced.

International standards like ISO 17020 (specifies requirements for the competence of bodies performing inspection and for the impartiality and consistency of their inspection activities) and ISO 17024 (contains principles and requirements for a body certifying persons against specific requirements, and includes the development and maintenance of a certification scheme for persons) are used to define the minimum requirements of inspection agencies and inspectors in technical specifications. These standards help bring about the parity between different agencies and inspectors who are being relied on for assurance of installation and fire safety.

Pillars for Fire Safety Of Facades

So, the three pillars described in the sections above and summarised in Image 1 are key to ensuring the fire safety of a façade implementation. Projects, where any one of the three gets less importance, can nullify the money and time spent on the other pillars.