Horrific fires involving the exterior walls of high-rise buildings have fueled debate over how to best mitigate rapid-fire progression on building exteriors. These fires represent a global challenge that begs for a solution. Recent exterior wall fires involving high-rise buildings have fueled discussion and debate over how to mitigate r a p I d – fire progression on the exterior walls that are clad with various construction materials.

To better understand the exterior wall flammability issue and move towards solutions, this article will:

- Discuss the factors that influence building construction related to these types of fires

- Provide an understanding of certain fire tests that are sometimes misconstrued as suitable for the evaluation of exterior walls

- Examine the importance of selecting tests for specific regions, codes, and regulations.

The article will also cover UL’s third-party certification approach that can be used to identify exterior wall assemblies that have successfully complied with required test methods. This information can hopefully be useful in preventing future exterior wall fires of these types.

In October 2019, the long-awaited Grenfell Tower Inquiry Phase 1 Report was released. The Grenfell Tower inquiry is a public investigation independently examining the circumstances surrounding the fire at Grenfell Tower that occurred on June 14, 2017. According to the inquiry report, a fire broke out on the fourth floor of the 24-story housing flat in North Kensington, London, and spread to the building exterior. It quickly raced up the building exterior, ultimately resulting in 72 deaths. The report can be viewed at https://www.grenfelltowerinquiry. org.Uk/phase-1-report.

Construction Considerations

There are several factors influencing exterior wall construction today. First, due to the fast pace of today’s construction and the need for less costly, easier-to-install designs, new materials are constantly being introduced into the marketplace. The combination of new and existing products creates an expansive list of exterior wall components options for designers and builders. The material combinations and their means of installation must be evaluated appropriately to determine whether they are suitable for use as a complete assembly. Fire testing has demonstrated that the testing of individual materials does not always result in a reliable determination of fire performance once multiple materials are combined into an exterior wall system. It is only through fire testing of the complete wall assembly that an accurate assessment of fire performances can be made.

Another challenge is the growing attention to building envelope performance such as thermal performance, air leakage, permeability, water infiltration, etc. In some areas, this is even driven by local codes and regulations. The result is insulation products with higher thermal properties and increased use of air barriers and vapor barriers. Consequently, these new wall constructions also require testing and evaluation for their conformance to the appropriate exterior wall fire requirements as a complete unit.

Another building construction factor is the increased use of exterior veneer materials that are aesthetically pleasing but lack evidence of compliance with codes or regulations for fire safety. Around the globe, especially since the Grenfell tragedy, there has been a strong focus on the challenges associated with non-fire-retardant metal composite panel construction, which is versatile and aesthetically pleasing but does not always perform well when subjected to certain exterior wall fire tests.

Holistic Fire Safety Approach

Many building professionals, fire protection experts, and design professionals are aware that taking a holistic approach to fire protection within buildings is ideal. This includes choosing materials that have been assessed for their reaction-to-fire properties (to slow the spread of fire) and considering detection and alarm, fire suppression, and compartmentalization. However, there is not always a clear understanding of which fire tests or protection approaches should be used for exterior wall fires.

For example, there have been discussions in some areas about relaxing requirements for exterior wall testing if the interior of the building is protected by sprinklers. For an exterior wall fire originating external to the building, it should be understood that the interior sprinkler system is not designed to protect the building’s exterior surface, so significant fire and smoke damage could still occur to the structure.

Selecting An Appropriate Fire Test

Another misconception is that the large-scale fire test conducted in accordance with UL 263 Standard for Fire Tests of Building Construction and Materials (ASTM E 119) which is used to establish hourly fire resistance ratings should be challenging enough to examine fire growth for an exterior wall assembly. This test method is useful for evaluating building assemblies for limiting the spread of flame between building compartments (utilizing walls and/or horizontal assemblies) or protecting structural steel members such as beams and columns. However, it is not intended to evaluate fire progression extending to the outside of an exterior wall assembly, which was an important factor in the Grenfell Tower and other recent high-rise fires, such as:

Monte Carlo Hotel, Las Vegas Nevada – 2008

Mermoz Tower, France – 2012

Lacrosse Building, Melbourne Australia – 2014

Torch Tower, Dubai UAE – 2015

Address Downtown Hotel, Dubai UAE – 2015

Grenfell Tower, London England – 2017

Torch Tower, Dubai UAE – 2017

Tests such as the NFPA 285 multi-story apparatus fire test are specifically designed to evaluate the ability of an exterior wall system to prevent an interior contents fire to leapfrog up the outside of an exterior wall system.

International Exterior Wall Test Considerations

In recognition of the importance of establishing the most representative test, there are various standards groups around the world focusing on exterior wall test methodologies. The good news is that the issue of flammability of exterior walls is being addressed seriously, and many jurisdictions are updating or creating new codes and performance standards. The challenge is that there are several different methods being implemented in different countries and regions that may not have the exact same scope or deliver the same outcomes. It is important to understand the methods used to qualify a product or system to ensure it is suitable for use in exterior wall construction.

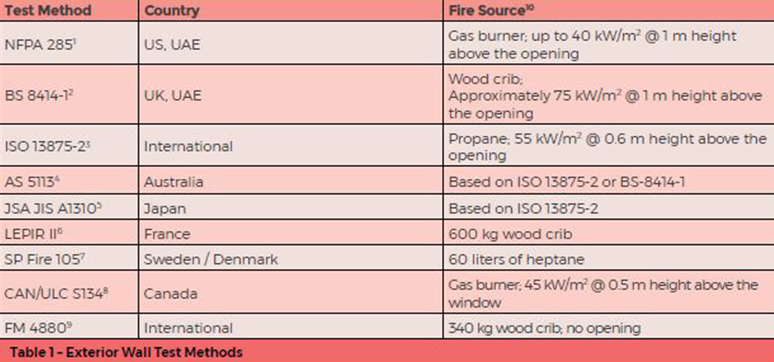

Many of these prominent fullscale exterior wall fire test methods are already embedded into codes and regulations. For example, the International Building Code (IBC) and NFPA 5000 make reference to NFPA 285 for buildings of Types I, II, III, and IV over 40 feet in height and buildings employing foamed plastics in the exterior wall. Table 1 lists some of the test methods and the countries where they are typically enforced. This is not intended to be a comprehensive list, as there are other methods under development.

Certification Approach

Historically, the acceptance of wall systems utilizing noncombustible materials involved a fairly complex review of building code requirements, test reports covering individual components, engineering analysis, and manufacturer’s installation instructions. With the increased demand and availability of combustible insulation products, combustible water barriers, and façade veneers coupled with the occurrence of several catastrophic exterior wall fires on high-rise buildings, fire prevention requires a robust fire testing and certification program for wall assembly systems is to determine that installed systems comply with the most current model codes and standards.

The Grenfell Inquiry Phase 1 Report states, “The widespread use of combustible rain-screen cladding panels and insulation on the exterior of buildings and the introduction of new kinds of building materials in external walls may have increased the risk of similar fires, but improvements in the regulations relating to fire safety and the requirements for testing and certification of materials, which will be a particular focus of attention in Phase 2, should be capable of mitigating that risk in the future.”

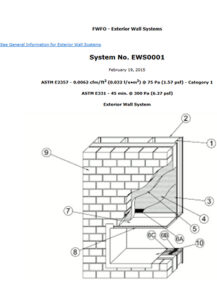

UL developed a certification approach to simplify the review process and ensure compliance with NFPA 285 by providing a public database that illustrates complete wall system designs and details how individual components are evaluated as part of a system. This approach meets the immediate needs of manufacturers, architects, specifiers, and code officials by providing an available, no-cost, accessible, and up-to-date method of determining compliance with a code. The illustrated designs within the UL certification reflect the precise details of a compliant assembly and are readily available to architects, fire safety experts, and code authorities.

For an exterior wall system to receive NFPA 285 certification from UL, it must be tested using the specific construction details provided in a manufacturer’s instructions. If a system is in compliance, a drawing of the exterior wall system and a description of critical construction components are documented in the UL certification information. Critical components used in the tested system are specifically identified and will also bear the UL Mark.

All certified wall systems and components are now published in the Product iQ online database in the categories Exterior Wall Systems (FWFO) and Exterior Wall System Components (FWFX). Examples of wall system components available through Product iQ include, but are not limited to, various types of insulation products (including foamed plastic), water-resistive barriers, air resistive barriers, laminates, sheathing, and composite panels.

Outreach

UL recently partnered with the International Association of Firefighters (IAFF) to develop a new demonstration and training video. The video will help educate the fire service on the fire behavior associated with these types of fire events and provide them with a better understanding of the test method NFPA 285. This video can be viewed at IAFF – UL Video Exterior Walls.

There is a continuing global focus on the challenges associated with rapid-fire spread on exterior walls. As UL strives to better understand the impacting factors, and the appropriate tests and certification approaches that can be used to evaluate these assemblies, we can move to offer solutions that will raise the level of fire safety for all.

References

- NFPA 285. Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Wall Assemblies. NFPA, 2019

- BS 8414-1. Fire performance of external cladding systems-Part 1: Test methods for non-loadbearing external cladding systems applied to the face of a building. BSI 2015

- ISO 13785-2. Reaction-to-fire tests for façades –Part 2: Large-scale test. ISO, 2002

- AS 5113. Fire propagation testing and classification of external walls of buildings, 2016

- JSA JIS A1310. Test method for fire propagation over building facades, 2019

- LEPIR II Test. Large-scale Fire Performance testing of construction systems for façade CECMI (French committee for the evaluation and the classification of products and elements of construction as regards to fire hazard – under the French Ministry of Internal Affairs directives), 2013

- SP FIRE 105. Issue 5. Large-scale testing of facade systems. SP Boras Sweden, 1994

- CAN/ULC-S134. Standard Method of Fire Test of Exterior Wall Assemblies. Underwriters Laboratories of Canada, 2013

- FM 4880, Class 1 Fire Rating of Insulated Wall or Wall and Roof/ Ceiling Panels, Interior Finish Materials or Coatings, and Exterior Wall Systems FM Approvals, 2010

- White, N. and Delichatsios, M. Fire Hazards of Exterior Wall Assemblies Containing Combustible Components. Quincy, MA. The Fire Protection Research Foundation, 2014