Since the time immemorial there have been endless discussions and debates on the system to be used for doors and windows in a building – Commercial /residential / so on and so forth.

Initially wood has been the architectural favorite. The warmth, the colour, the grain, in short simply the life a wooden window brings to a window opening is remarkable and unmatched. But, it comes with its own limitations. Its sensitivity to harsh climatic conditions, its proneness to various degradation factors vis-à-vis moisture, salty air, woodworms, and adverse environmental effects of timber harvesting led to the exploration of various alternative materials. Then arrived aluminium. Fast forward a few years, another technological advancement called uPVC windows.

Along with this commenced the unending battle of Systems. Try searching the ‘Google’ master for aluminium and/or PVC and like a skilled magician he takes out 16500 results in mere .34 seconds from under his magic hat. The window manufacturing companies seem to derive utmost pleasure in showcasing the comparison in a most fancy and dramatic manner on their websites. However, noteworthy in those comparisons is one uncanny similarity – the best aluminium is compared with the worst possible uPVC product and if it’s a uPVC company’s literary genius the comparison is between their best quality uPVC system and a downgrade worst possible aluminium system. So where did the age-old marketing saying – “an apple-to-apple comparison” go? Or is it always my apple is sweeter than yours?

In this article, we shall try to explore various good and not-so-good qualities of similar-level aluminium and uPVC pitching them against each other.

After the successful completion of the debate there are chances that we get two pure strategy Nash Equilibria –

- Where everyone agrees aluminium is the best

- Where everyone agrees uPVC is the best

There is also a possibility (a very high one) that a mixed strategy equilibrium is achieved.

Working out the above let’s consider the important factors that are considered while choosing a window system:–

a. AESTHETICS – A window in a building is not only an architect’s vision or an owner’s pride, it’s also the window to their humble (or not so humble) abode. As far as looks are concerned, although mostly it’s a personal choice, it’s wood that takes the cake hands down. Both aluminium and wood try to immolate the wooden feeling, but nothing matches the originality of the wood. But if we have to choose between the two, aluminium will take precedence over uPVC due to its natural feel, its rich natural anodized finish (if there is one), for its slim, clean geometric lines.

But there is always a counter view for a view as Mr. KR Suresh – Director Axis façade Says – although aluminium is my first choice, if I am making my own villa, I will use uPVC windows for their sheer elegance.

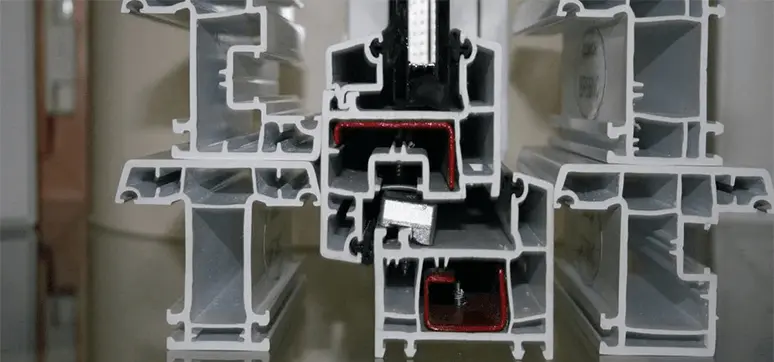

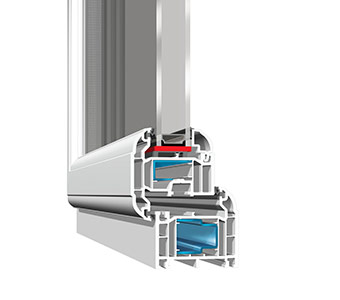

b. SAFETY and SECURITY– While selecting a window system safety and security are the key concerns. While a lot more defines the safety and security of a window besides the profile system used, like glass; hardware; also the window design, still profile is still given the utmost importance. Aluminium due to its inherent metallic nature is sturdier while uPVC being a plastic lacks the inherent structural strength. But this is well taken care of by the use of steel reinforcements of required static and dynamic load-bearing capacities.

A lot of system companies are now present in India for both aluminium and uPVC and are equipped to incorporate the best fittings to ensure proper security. Euro grove is a standard and most high-security fittings can be incorporated into almost all the systems

Both aluminium as well as uPVC system profiles can incorporate various configurations of glass be it tempered, laminated, or insulated-laminated, thus ensuring both are at par.

However, one factor that favours aluminium in this battle is that aluminium can be used in extremely high wind load conditions because of its unmatched strength-to-weight ratio. Great static strength can be achieved even with slim sightline profiles. This fete is unachievable by uPVC sections as for higher static and wind-load requirements, it has to incorporate bigger, heavier sections of steel reinforcement. This makes the uPVC sections bulkier and broader, which may not be preferred by the architects for obvious aesthetic compromise.

c. FUNCTIONALITY & APPLICATION – Various types of window systems are possible in both aluminium and uPVC. Casement, awnings, tilt & turn windows, sliding, fold & slide, tilt and slide etc.

More than the material, it’s about the system design. With various system companies now active in India for both aluminium and uPVC, any typology of the window is possible with either of the systems.

However for façade application, aluminium is the preferred choice because of the strength advantage. Although various uPVC companies like Rehau Polymer and Profine India Window Technology Pvt Ltd have special systems for curtain wall application, they are not very popular amongst users. Lack of awareness or even non-availability can be the reason.

D. INSULATION – Here comes the bone of contention. This is one area where the battle goes real. With the increasing use of air-conditioning and resulting high electricity bills, the end user is now opting for various insulation techniques to cut down on the bills and to increase savings. Aluminium is inherently a conductive material, while uPVC is not. Comparing the conductivity of the base material – aluminium’s U-Value can go up to 7 watts/m2K, while a basic uPVC system shall have a U-Value of less than 3. But a window has to be considered as a complete entity. It has been observed through various studies that depending on the total area of a window, as much as 51% of the heat is lost through the framing material. So framing material also should be appropriately insulated if we need to achieve optimum insulation values for the complete window.

But the buck doesn’t stop here. There are a lot of technological advancements whereby aluminium’s conductivity can be reduced. Systems made of highly insulating but rigid material (glass-reinforced polyamide) are used to create a thermal barrier between the inside and outside of an aluminium profile. This can help in achieving U-Values as low as below 1 W/M2K

Likewise in uPVC by means of system modifications and multi-chamber designs U-values less than 1 W/m2k can be achieved.

There are two schools of thought where noise insulation is concerned – One advocating aluminium systems for better noise isolation saying aluminium being a denser material is able to dissipate sound waves more efficiently. The other school of thought says since uPVC systems are sealed from all sides with fusion joints and the possibility of co-extruded gasket arrangements, they perform better in the sound insulation front.

e. ENVIRONMENTAL CONSIDERATIONS – Fortunately the design culture is moving towards more responsible architecture that starts to consider the impact of the built environment on the global environment. The buildings strive to be more energy efficient with correct design philosophies. A closer look at the embodied energies of the materials used and of the building as a whole is sought.

The Australian CSIRO (Scientific and Industrial Research Organization) states that the energy consumed in the manufacturing of building materials is highly correlated to CO2 (Carbon Dioxide) emissions. An average of 0.098 tonnes of CO2 per GJ of embodied energy is produced.

The embodied energy of a window system will comprise 2 components – initial embodied energy and recurring embodied energy. An aluminium window frame will have the initial embodied energy that is derived from the mining of the ore, its melting and processing, the transportation of the steel to the window manufacturing plant, the manufacturing of the window frame and its transport to the building site. Initial embodied energy is influenced by the source and type of the materials and the nature of the building. Recurring embodied energy is non-renewable energy consumed to maintain, repair, restore, refurbish or replace materials, components or systems during the building’s life span For example, a window frame that is not sufficiently protected from rust or other environmental deterrents might have to be replaced, or painted. Recurring embodied energy is influenced by the durability and maintenance of materials, systems and components installed, and the life span of the building. As the life span of a building increases, the operating energy significantly increases. Thus it’s imperative that the chosen system has the least maintenance repercussions.

Aluminium, a material of high paradox has an extremely high embodied energy when initially extracted and manufactured. However, its recycling is relatively cheap and easy and by weight has the embodied energy comparable to that of particle board (8.00 MJ/kg). Primary aluminium production has large-scale negative impacts on the environment. Alumina refining uses on average 75kg of caustic soda and 48 kg of lime per metric tonne of alumina. The fuel consumption and energy consumed in the manufacturing of lime and caustic soda supplementary materials are responsible for 991 kg of CO2 equivalents per metric tonne of alumina. However, once used as a building material, Aluminium has a very long lifespan. It is one of the most durable products on the market, and highly recyclable. The cycling of Aluminium allows for large savings on the production of greenhouse gases.

On the other hand, the embodied energy of uPVC is a great deal lower than aluminium (at approximately 80 MJ/Kg as against 227 MJ/Kg for aluminium). It is made of 57% rock salt and 43% of crude oil. Approximately 8 tonnes of oil is used for every tonne of uPVC.

Maintenance of uPVC also doesn’t require many resources. The fact that no external preservatives or paints are required and that it will never rot or corrode is an added advantage. Although uPVC is also 100% recyclable, a lot of different formulations are in use and additives that are homogenous in nature make it a relatively difficult task.

f. COST EFFECTIVENESS – If we compare similar performance aluminium and uPVC framing systems, uPVC is less expensive as of now in India.

The debate is endless and discussion can go on and on. We can include various other criteria as well. But, after discussion and pondering over the above set of Criteria, we hereby decide that both systems have their advantages and disadvantages. They have their own share of the market which will overlap here and there, but there is no denying that both will co-exist together in the Indian market for a long time to come.