Performance glass is a glass that provides benefits to its end users (building occupants). The glass helps in achieving benefits for the structure like reduced HVAC loads and light comforts. The need to have different types of glass on façades arises due to many factors such as local climatic condition, external wind pressure, building occupancy type, building geometry, area of application etc. Energy Efficiency not only plays an important role in society but also plays an important role in shaping the future.

While choosing performance glass, two aspects are to be taken care of by the occupants:

a) Optimise light to reduce the need for artificial light

b) Cut down the heat inside building to reduce the load on air conditioning

The selection of the right type of performance glass for the building envelope is critical for building efficiency point of view. We continuously work to create new glass products and solutions using the most advanced technology to help customers see what is possible. Architects and building owners want high performance glass coated products that deliver optimised natural light combined with energy savings and solar protection. The multi-functional coatings offer high selectivity solar protection for a wide range of applications such as fully glazed façades, roof glazing and large framed windows.

The Need For Glass Coatings

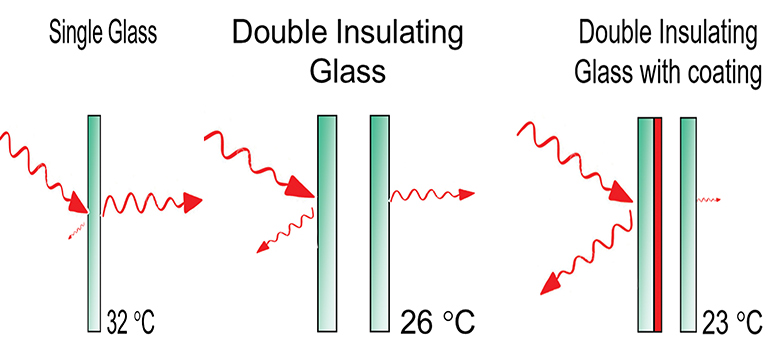

The physical definitions of light, energy and heat are described by defining wavelengths of the electromagnetic spectrum. When radiation hits an object, certain wavelengths are reflected, absorbed and transmitted through the object. Coatings are applied to float glass to manipulate which wavelengths are reflected, absorbed and transmitted to serve functional and aesthetic requirements. For example, designing glass coatings that reduce solar heat requires controlling the radiation emitted by the sun that strikes the earth. Coatings are designed to reflect the solar radiation (solar heat) while at the same time transmitting a significant amount of the visible light wavelengths (daylight) through the glass.

Applying Coatings to Glass

Float glass coatings are produced in huge quantities, primarily in two techniques. One is the chemical pyrolysis process, also called hard-coating, which occurs online during glass production on the float line. Metal oxides are permanently baked onto the surface and are very hard (hard coatings) and resistant, but their properties are very limited due to their simple structure. The second coating process is called vacuum deposition process or magnetron-sputtering. Magnetron sputtering deposits metals and metal oxides onto glass perfectly smoothly in a sequence designed to achieve outstanding optical and thermal properties. Glass is sent to into a coater with vacuum chambers, each designed to apply a particular material layer to the glass.

The material (the target, which is a metal plate or a tube) that is going to be deposited on the glass surface is mounted on an electrode that has a high electrical potential. Electrode and material are electrically isolated from the wall of the vacuum chamber. The strong electrical field (fast electrons) ionizes the sputter gas argon. The accelerated argon ions can break off material from the target by colliding with it, which then comes into contact with the glass, where it is deposited onto the surface evenly.

Three Main Criteria For Modern Facade And Fenestration

A. Solar Control Glass for Façades

Window & Roofs Solar control glass allows sunlight to pass through a window or façade while radiating and reflecting away a large proportion of the sun’s heat. Solar control glass can help improve the energy efficiency of a building, as it reduces the need for air conditioning during the warmer summer months. The indoor space remains bright and much cooler than would be the case if the standard uncoated glass were used.

A variety of solar control glass products are available in the market, depending on the level of solar control required and are often specified for large glazed areas, façades, conservatories, windows, skylights and roofs, Some of them (like Guardian SunGuard®DS Series) use advanced coating technology to create glass with an optimum selectivity ratio, high light transmission, low solar factor, neutral appearance and optimum thermal insulation. Many products combine solar control, light transmission and low solar heat gain properties with a range of colours and appearances to suit any application.

Architects and consumers are demanding greater solar control and thermal insulation of their building envelopes to satisfy economic, ecological and comfort requirements. We are working tirelessly to enhance building performance without sacrificing the natural light people desire. The motivations behind greater solar control and thermal insulation are:

• Economic

Building owners and managers are willing to invest in solutions that will reduce their energy costs. Technological advances of the last three decades have produced systems and equipment that can coat high tech insulating glass with razorthin, neutral coatings using lowcost processes. This technology is now applied to millions of square meters of glazed areas of windows and façades.

• Ecological

Consumer and industry awareness of environmental sustainability has grown rapidly within the building industry. Due to its natural ingredients and superior energy-balancing properties, glass is a key element to reduce heating and cooling costs and to achieve the goals of globally recognised certification programs for building sustainable and environmentally friendly buildings.

• Comfort

Better solar control and thermal insulation reduce unpleasant drafts from glazing areas, without sacrificing the benefits of daylight that make people feel better and more productive.

• Superior aesthetics

The Colour Rendering Index is one of the measures for measuring the ability of transmitted daylight through the glazing to portray a variety of colours compared to those seen under daylight without the glazing. The scale is 1 – 100. For instance, a low Ra value causes colours to appear washed out, while a high Ra causes colours to appear vibrant and natural. In the commercial glass, Ra indicates the effect the specific glass configuration has on the appearance of objects viewed through the glass.

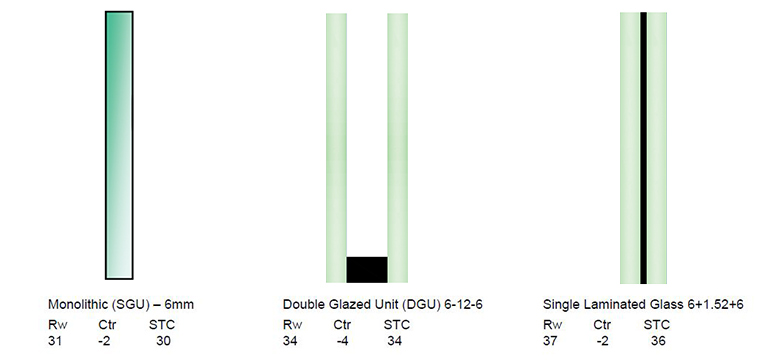

B. Noise Control Glass

Sound is normally transported both through the air and through solid objects. The intensity of the variability in pressure is called sound pressure and can be extremely variable, from the ticking of a clock to the crack of a gunshot. Three methods are used to control a wide variety of sounds:

• Pane thickness

The rule of thumb is that generally, the thicker the pane per surface unit is, the greater the noise reduction. Therefore, insulation efficiency increases as glass thickness rises.

• Insulating structure

Double or triple insulating glass is a mass-spring-mass system: both outer panes (masses) are separated from each other by the air or gas that fills the interspace (spring). If glass panels of the same thickness are used, the sounds get transmitted from one to the other pane nearly ideally (resonance). Only asymmetrical insulating glass build up’s can improve the sound insulation significantly. The interspace muffles the vibrations from the outer pane before they reach the inner, second pane, with the rule being the bigger the interspace, the more effective the noise reduction. But this is only possible to a limited degree since this process also reduces thermal insulation.

• Lamination

The noise-reducing effect of thicker, heavier glass may be further optimised by using a flexible interlayer (PVB) to connect two single panes of glass. With this solution, the thickness and space weight remain the same; the pane, however, gets “softer” and thus increases its insulating capacity by damping the sound waves.

C. Glass Design Options

For centuries, generations have used glass for filling “light holes” in massive outer walls. This has drastically changed in the last three decades. Today glass itself forms and shapes the space and creates room enclosures, thus creating transparent architecture that allows people to feel close to nature. A glass’s finish on a façade has always influenced its reflective properties, which can range from being produced so that the glass is very reflective, reflects an overall colour, or has a weak reflection.

• Screen-print technique

The screen-print, which is mainly dedicated to painting partial areas and used for a specific design, colour which joins firmly with the glass surface and coating in the following tempering process. This technology is adopted for larger quantities and is ideal for parapet glasses components is less suitable for larger areas and homogeneous painting.

• Design glasses

Transparent elements can become more and more visual and functional decoration facets. From etching and shot blasting over the ceramic screen-print up to laminated glass with inside foils, the design can be a decorative ornament or symbol or also an all-over illustration or matting.

• Screen-print directly onto the glass

The colour screen-print directly onto the glass has a long tradition. The enamel or ceramic paint which is a mixture of small milled glass and joining colour pigments is pressed with a scraper through the open parts of the sieve into the glass.

• Transfer colour print on glass

The transfer print offers an alternative to achieve a multi-colour print instead of the single colour screen-print. Also, enamel and ceramic colours can be transferred via digital print on transfer foils and can thus reproduce multi-colour motives. These printed foils will then be fixed with glasses that are going to be tempered. During the tempering process, these foils will burn residue-free and the painted colours will join as previously described.

• Coloured foils in laminated glass

Within the same lamination process exists a large pallet of different colour foils, which can be combined to achieve each imaginable colour in laminated glass.

• Bent architectural glass

Architects and designers love to interrupt straightness, corners and curves with soft curves. In the applications of the building envelope, glass is generally bent through a thermal gravity process.

A glass pane is laid over a bending form and in the bending oven heated up to 550 – 620ºC. After having reached the softening point the pane descends (through gravity) slowly into the bending mould and adopts its shape. The following cooling down defines the shape of the performance glass. Slow cooling, free from residual stress, produces a glass which can be further processed, whereas fast cooling creates a partial or fully tempered glass which is not applicable for further processing.

Conclusion

It is important to choose the right kind of glass, considering the objectives like colour, safety and comfort-related factors such as sound insulation, thermal insulation and glare control. The right amount of light, heat and sound passing through the window is crucial to the comfort of the building occupants, therefore it is essential to choose the high- performance glass solutions. Selection of the right type of performance glass is critical for building efficiency too.