When designing the building components such as the facades, windows, and doors, we need to ensure that the products don’t just look great but perform to the highest possible standards without the risk of deterioration. Efficient, productive applications need adhesives that provide high durability in a cost-effective, easy-to-use manner. 3M™ bonding technology is a high-strength, reliable and affordable alternative to traditional fastening methods and is a reliable alternative to screws, rivets, welds and other mechanical or thermal bonding solutions. 3M™ adhesive technology creates a stronger bond while weighing less and giving a clean design and consistent appearance.

The façade is the most important part of the building envelope responsible for a range of functions, most importantly the primary weather defence and architectural aesthetics. Metal has been included in architectural façade designs, windows & doors for the routine smooth skin design for commercial and residential buildings.

The designers have embraced metal for its flexibility and finish, as well as ease of fabrication and installation as it can be connected and attached to a building in a wide variety of ways. However, the thinner metal panels do not have sufficient stiffness to resist deflection and damage during wind load events and require additional intermediate stiffening via attachment of a metal profile bonded to the rear of the panel. The attachment of the stiffener system is critical to the structural performance.

Stiffener Bonding Methods

A variety of stiffener bonding methods are commonly used –mechanical fasteners, structural silicone adhesive, and high-performance pressure-sensitive acrylic foam tapes. Two methods of stiffener attachment are commonly employed: connected or floating stiffeners.

3M™ VHB™ Architectural Panel Tapes and 3M™ VHB™ Tape GPH-160 are high-performance, all acrylic, foamed pressure-sensitive adhesives, dedicated to use in the fabrication of architectural panel systems. These tapes are fast and easy-to-use, and give consistent bond lines for permanent, high-strength attachment with long-term durability, with stiffener applications since 1980.

3M™ VHB™ Architectural Panel Tapes provide immediate handling strength during the fabrication process and do not shrink after curing, as do some liquid-applied sealants. This shrinkage can result in isolated panel stress that may be visible on the exterior face of the architectural panel. With 3M™ VHB™ Tape GPH-160, stiffeners can be attached prior to liquid paint or powder coat processes involving a paint-bake cycle or post-paint – further improving productivity. 3M™ VHB Architectural panel tape is a single-component system that reduces the number of steps compared to liquid adhesive – which requires “spacer” tapes to form the required bite height as well as the potentially inconsistent application of messy liquid adhesive. 3M™ VHB Architectural Panel Tape can be pre-applied to stiffeners in bulk using automation – further increasing production efficiency.

Structural Performance of 3M™ VHB™ Architectural Panel Tapes

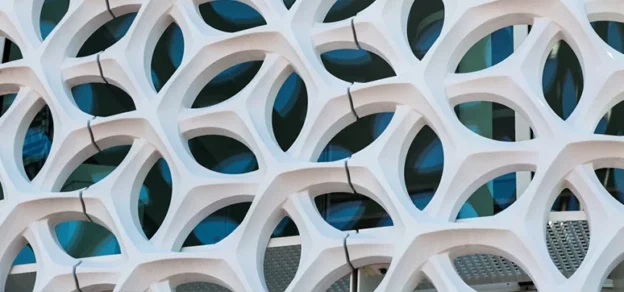

We compared the structural performance of a number of different floating stiffener attachment methods on 3 mm solid aluminium panels at a 3rd Party Laboratory – Intertek laboratories, using ASTM E2264-05, ASTM E330/E330M-14, ASTM E1886-13a & ASTM E1996-14a. Panels were subject to 1.9 kPa, up to 3.8 kPa cyclic pressure loading and 5.8 kPa held for 1 minute. The study demonstrates the structural adequacy of Silicone Adhesive and 3M™ VHB Architectural panel tapes for stiffener bonding and compares both bonding methods to welded stiffeners.

To see the study follow the link

http://www.digital.metalconstructionnews.com/publication/m=65786&i=716079&p=30&ver=html5

3M™ with an extensive global experience in the field of adhesive technologies for the window and door industry that ensure aesthetics and durability as per industry standards. The products are highly compatible with a range of substrates such as aluminium, uPVC etc. that can reliably stick and seal the building components.

Window Application

Window Application

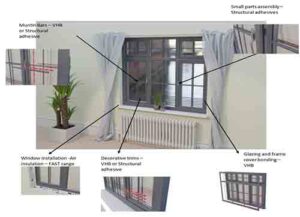

With the reliability of adhesive technology, we can stick and seal the building components from muntin bar installation to window sealing. 3M™ tape and adhesive bonding solutions make window manufacturing applications quick and easy. They provide high-strength, reliable bonds that are resistant to environmental conditions while maintaining a clean aesthetic. Our adhesive and tape solutions make it easier than ever to manufacture frameless windows, so you can meet this growing trend in the architectural market.

The picture depicts a window with all the relevant applications that we can offer a solution.

Door Application

Door Application

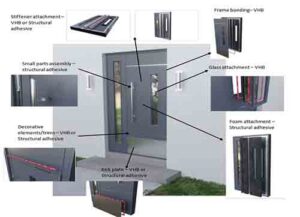

3M™ provides solutions for applications with challenging substrates and processes such as powder-coated materials or operations that require high-temperature resistance. By simplifying the manufacturing process with 3M™ tapes and adhesives, you could save time while producing more units and increasing your efficiency.

3M™ Adhesive Technology

3M VHB ™ double-sided adhesive tapes are a valid alternative to screws, rivets, welds and other fasteners mechanical, which allow to speed up the production process thanks to the simplicity of application and immediate gluing. Thanks to their structure, 3M VHB ™ belts can conform to surface irregularities, compensating for small inhomogeneities in surfaces.

Whatever your bonding needs be, the 3M™ Scotch-Weld™ Structural Adhesives and 3M™ Adhesive Sealants give you advanced strength and durability with limited odors and an improved aesthetic. Replace traditional mechanical or thermal methods for fast-bonding, high-strength adhesion without visible fastenings or weld spots. 3M™ Scotch-Weld™ Structural Adhesives and 3M™ Adhesive Sealants produce a seamless appearance, making products lighter and more efficient and giving you better design freedom thanks to their ability to bond dissimilar materials. They’re more time efficient as there’s no need for energy-intensive thermal bonding or time-consuming drilling.

These products are tested for the stress distribution in the bond line that helps to control the deflection of the metal panels. The stiffeners applied for extra support in the metal panels attached with 3M™ adhesive technologies can reduce the panel deflection while maintaining rigidity. It is also ease the attachment of stiffeners while increasing the final aesthetic, with stress-resistance capability and process flexibility. These products are evaluated as per the industry-accepted ASTM test methods to determine the structural integrity, pressure cycling, wind loads and environmental conditions. These are tested in third-party laboratories for various applications. These are tested in third-party laboratories for various applications. These products also decrease the chance of galvanic corrosion in the case of different metal attachments.

Flash, Seal and Seam with 3M™ FAST Range Tapes

The 3M™ building envelope systems help manage the flow of air, vapour, and heat as well as, when necessary, containing fire and smoke so people have time to move to safety. The building envelope is crucial for making any building a long-term success.

The 3M™ building envelope systems help manage the flow of air, vapour, and heat as well as, when necessary, containing fire and smoke so people have time to move to safety. The building envelope is crucial for making any building a long-term success.

For sealing, weatherproofing and flashing, use 3M™ FAST tapes. These high tacks, UV-resistant, and highly conformable tapes stretch to fit sills, curves, and corners in a single piece for an airtight, waterproof bond without joints or seams. The easy, hassle-free installation is up to 60% faster than conventional sealing methods. 3M™ acrylic flashing tapes can be applied from extreme cold to high heat and to many different construction materials. These flexible tapes are stretchable and conformable for tight seals around uneven surfaces, even when penetrated by nails or staples. Designed for multidirectional applications in commercial buildings, enabling fast and easy detailing of windows, doors and penetrations.

The test standards ASTM E783 and E1105 measure the air leakage and static water penetration for the exterior building components such as windows and doors. The leakages can result in condensation inside buildings leading to high costs for maintenance and decreasing the energy efficiency of the building. It can be mitigated by the proper installation of the building components arresting the leakages.

Conclusion

3M™ uses science and technology to improve lives and provide innovative manufacturing solutions around the world. A market leader in bonding technology, 3M™ tapes and adhesives are used in countless industries thanks to their unwavering reliability and ease of use, making them some of the most popular on the market. We collaborate with our customers to help them develop lighter, more attractive, longer-lasting products with better flexibility when designing and selecting materials. The adhesive experts can provide you with the best technical advice for choosing the right solution for your operation. Through individual laboratory testing, we can recommend the best products to fit your production line based on stability and durability to give you a unique, personalized solution.

These applications can also be assisted with semi or fully-automatic bonding equipment in the production facility. We also help to train the installers, plus have a world-class team of engineering experts to help answer questions when you come across new situations. From the planning stages through construction to final documentation and inspection, we want to help make the application a successful part of your project.

Unlike traditional fastenings, there’s no need to drill holes in the substrate, mitigating the risk of future corrosion and substrate fatigue. With simpler processes and less downtime in drilling or curing, you can increase productivity and efficiency on the production line. 3M™ solutions can help to keep up to date with manufacturing technology with expert advice to simplify the process and keep the operations running smoothly. We can provide solutions for applications with challenging substrates and processes such as powder-coated materials or operations that require high-temperature resistance.

For more details, please visit Bonding Products and Assembly Solutions | 3M

3M™ has a broad portfolio of building envelope solutions including air barriers, fire protection, structural glazing and assembling the systems with bonding technologies. The 3M™ Building Knowledge link http://www.3m.com/BuildSmarter helps to explore systems and products for the commercial construction industry to Build Smarter. We facilitate and support fire science and engineering programs which can deliver practitioners and researchers with the capabilities how to integrate fire safety performance for a building.