The construction of buildings has evolved to newer heights in the past few years, and so has the awareness of conserving energy. With the Kyoto Protocol signed so many years ago and increasing global awareness about climate change, even a school student is now aware of energy conservation.

In any given building, its envelope is the main point of heat exchange. As much as 41% of energy might be lost from the fenestration depending on the window-to-wall ratio.

If we look at a picture of a house from a thermal camera (Fig 1), we will notice that the brightest red lines, or where the heat is transferred most from, are the frames of the windows, yes, even more than the glass. Energy finds the weakest point between the walls, frames, and glass to pass from. It is apparent in the above thermal analysis, where the isothermal lines are very constant at the glass level, but there is more activity at the level of the frame where the energy flow is higher.

Until a few years ago not much importance was given to Fenestration and was mostly hidden behind the curtains. Today the fenestration area has come out of the curtain and is like to be shown off. Aluminium is vastly chosen among available options and due to its strength, structural stability it provides and ability to be coated in any colour or finish desired it surely is the most durable and aesthetic product. With the aluminium window systems companies operating in the Indian Market, there are plenty of solutions today for highrises, double height windows, minimal sight line windows, etc. and of

course, you cannot have a glass façade without aluminium framing behind it.

But can aluminium windows be energy efficient? Can they improve acoustics? The answer is yes. Aluminium windows with thermal breaks are highly energy efficient. If used with the proper combination

of glass, they dampen the noise effect also.

A pertinent question is asked many times, Does India with its tropical climate need thermally broken windows? On looking at the climatic data, one would say it does not. But a closer look at the reality may force us to change our minds. India is the 6th largest energy consumer in the whole world. Today, in almost all the semi-luxury apartments in the major Indian cities, and in all of the commercial buildings we find extensive use of air conditioners which constitutes a major portion of the total electricity consumed. The difference between inside and outside temperatures has risen and with it the need to create a thermal barrier between inside and outside to prevent energy loss.

When we compare the 2 windows, non-thermal and thermally broken (with one window open to show the source of heat), using a thermal camera, we can see that with an external heat source of about 61 deg. And an inside temperature of about 19 degrees, the surface temperature of the frame in a non-thermal window is about 30 deg. And in the case of a thermally broken frame, we have about 26 deg. For those of you who are Mechanical Engineers, I think you will appreciate the air conditioning power it takes to cool a room with 4 deg.

The use of double glazing is now a necessity. In a scenario where double glazing is used in a non-thermally broken aluminium frame, there is always a possibility of energy loss in the tune of 80%. So the energy saved by the double glazing is lost through the non-thermal frame. In ideal conditions, it is found that you save around 30-40% of your energy by using thermally broken aluminium frames with double-glazing units.

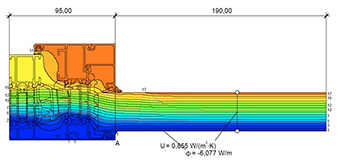

Here is a comparison of 2 almost identical systems (Fig.3), one without a thermal break and one with a thermal break. You can see the difference in the internal temperature and the heat flow inside the frame. A typical non-thermally broken window will have a U(f)-value of over 6 W/m2K, while that of its thermally broken counterpart will come out to be around half.

We also see the thermal lines where the glass is almost constant and the thermal action is mostly in the frame (Figure 4). You can see from the small movements in the frame that this is a very well-isolated system. So this is saying that if we have a temperature of zero degrees outside and 20 deg. inside, the surface temperature of the frame is about 17 degrees, which is very good isolation.

Thermal break aluminium profiles use an isolating strip made of Polyamide with 25% glass fibre in a 3D structure to provide insulation. It is a thermo-plastic material that is 500 times less conductive than

aluminium at the same time is structurally stable due to the glass fibre content. Figures 5 and 6 show the

working of a typical thermally broken window and a curtain wall.

The rate of expansion and contraction is similar to that of aluminium. So it acts as an integral unit

without any risk of derailing.

It is observed that as you increase the width of the insulation area and as you break them down into

smaller chambers, the better insulation you get.

There are many examples in the country using this system successfully like in the Hospitality Industry. Some examples are:

- ITC Grand Chola (Chennai),

- ITC Park Sheraton (Chennai),

- Hotel Leela (Chennai and Goa),

- Hotel TAJ GVK (Mumbai),

- Hotel Crowne Plaza (Cochin),

- Hotel Wyndham (Delhi),

- Hotel City Park (Delhi)

Other most recent examples are the All India Institute of Medical Sciences in Bhubaneshwar and 4 other cities currently under construction.

Even residential projects are not behind: DLF Magnolias in Gurgaon (Fig.9) was one of the first residential projects to use a thermally broken aluminium window system. Many more residential projects like Pooja Constructions in Mumbai (a 17-storeyed building) are currently under execution. Therefore there is certainly a growth in awareness and need for these systems in India.

The Government of India through its Bureau of Energy Efficiency has launched a programme for Energy Conservation Building Code (ECBC), which involves the construction sector. The ECBC code was launched in 2006 with an implementation date of January 2014. As of now, it is already mandatory for the Central Government Projects to be ECBC compliant and various state governments are in the process of launching their own state ECBC codes which are far more stringent. In the 12th five-year plan (2012-2017) the target of the Government of India is to have 75% of its new buildings to be ECBC compliant. In addition, 25% of the existing buildings are to be retrofitted to be ECBC compliant.

Currently, Aluminum window systems companies like Kawneer, Reynaers, EFP, Ponzio, Profils Systemes, etc. are established in India and actively promoting thermally broken aluminium window systems. Indian

Fabricators, such as AGV Alfab, Alamdar Fabricators, Thermaline, Durall, etc. have designed indigenous

thermally broken window systems.

Technoform Bautec, being the global leader in manufacturing polyamide strips for thermal break aluminium profiles, is always at the disposal of system companies, façade & window manufacturers, developers, architects and government agencies to recommend and advise ways and means to conserve energy

through thermally broken aluminium fenestration systems.