India is a developing country and also the second most populous country in the world. Our cities are growing taller and taller and the industry is demanding energy efficient and clean looking systems. Traditional construction in India has always been a brick and mortar type of construction. But since last decade, we are seeing a huge increase in highrise structures with facade systems. Every technology and material has its benefits and associated risks. Façade related fire safety risks are one such risk, which are still at premature discussion level and needs a lot more attention.

In a practical scenario, we often discuss as to how to respond when a fire occurs.

What we often ignore is that how to get such fires contained under one compartment itself and restricting its faster spread without relying solely on fire department. Except very few, many of our states do not even recognise firestop systems under their ‘No Objection Certificate’ check parameters. Recent fires in Dubai and the Grenfell Tower fire accident in London raised back the question of façade fire protection again. Luckily for us, the National Building Code of India had also been revised after almost 11 years and this time it also brings forward some good points regarding facade fire safety by restricting its growth at the perimeter void itself.

Little History

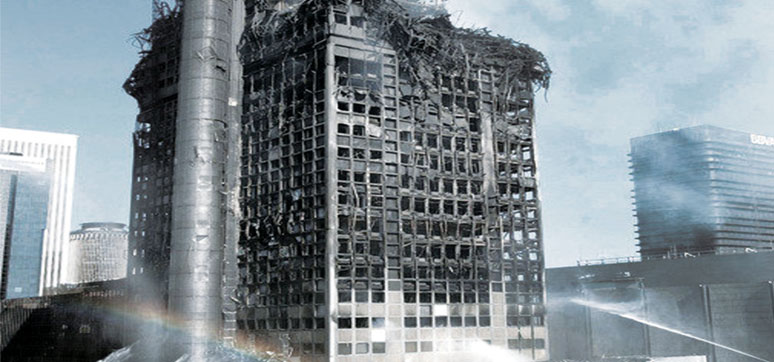

In 1988, First Interstate Bank Building in Los Angeles caught fire on the 12th floor extending to the 16th floor in a 62-storey building.

“The lack of firestopping between the floor slabs and the skin permitted the fire to spread from floor to floor through this space. Fire was observed spreading through this area even before the glass and mullions failed,” said the Chapman, Elmer F. “High- Rise: An Analysis,” Fire Engineering”, August 1988 report.

It was identified as per the investigation that the fire was originated on the 12th floor and spread to upper floors via lift shaft and the unprotected opening at the edge of the floor slab and facade system.

India has also suffered its share of losses from such high-rise fires. Mantralaya fire and Lotus Business Tower fire in Mumbai are a few examples of such losses, we had seen.

There are many examples but through such losses, it was observed how critical it is to address the fire risks associated with facades. There are multiple ways by which fire can grow from the façade and slab assembly point.

Each of these paths shall be addressed by evaluating it separately. In India, unfortunately we do not have a specific test standard to evaluate such systems, but internationally there are some standard available from NFPA codes which establishes different requirements for each potential path and address the means to protect the paths or to prevent the spread of fire based on each separate one. During the recent revision of National Building Code of India 2016, perimeter fire stopping was also recommended under clause 3.4.10.2.

Why is this so important? To understand this, we have to go back to the basics.

As we all know that curtain wall structure is a multi-storey structure where exterior walls are not part of the load bearing structure. As the common construction methodology, the floor slabs are supported by interior beams and columns. And, we mostly encounter a perimeter void typically of the range from two to eight inches between each floor slab and the exterior curtain wall.

Perimeter voids are generally hidden from view after construction, and once installed, due to their location, such construction gaps are never inspected or reevaluated unless some major retrofitting comes by. But when such openings are left unprotected, they provide the perfect space for the fire and smoke to spread upwards. Such a spread of fire when reaches to more than one floor also.

weakens the sprinkler system by overtaxing its design criterion and makes it almost impossible to control with available systems. Hence, these openings must be sealed to prevent spread of flames, smoke and toxic gases in case of fire breakout.

As with all passive fire protection systems, the intent of sealing the edge of the slab opening with fire and smoke resistant system is to confine fire to its room of origin and prevent its propagation through the floor, ceiling, or walls. With ineffective curtain wall and perimeter void fire protection, fire can spread through the space between floors and walls, through the window head transom and the cavity of the curtain wall, or through broken glass or melted aluminium spandrel panels.

The mechanism of fire spread in a curtain wall is primarily through chimney effect, leapfrog effect and poke through effect.

Chimney Effect: Chimney effect is attributed to the spread of fire upward through the available openings between the floor slab edge and the curtain wall.

Leapfrog Effect: Leapfrog effect is seen in mid- to high-rise building fires where flames blasting out through perimeter windows leaps through the windows above and continue to spread vertically by following similar effect every floor.

Poke Through Effect: Poke through effect is where flame and hot gasses penetrate through openings in firerated walls and floor/ceilings ignite combustibles on the other side.

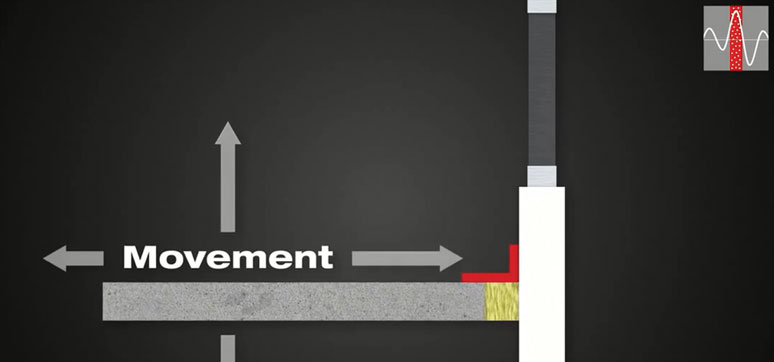

Perimeter fire barrier systems are used to resist the interior propagation of fire through the gap between floor and exterior wall for a period equal to the floor’s fire-resistance rating. Additionally, all the building components are subject to various movements such as thermal, wind or seismic. Hence, a building’s perimeter fire barrier system should accommodate various movements,such as those induced by thermal differentials, seismicity and wind loads.

Curtain wall design became common in the west in around 40 years ago, but in India it has started to gain huge momentum hardly a decade ago. Inherently, this comes along with multiple risks as well, such as fire and smoke. In India, as such, for now there is no test standard to test and evaluate such system as one to really identify the fire and smoke performance of such systems. However, there is a standard called ASTM 2307 “Fire resistance of perimeter fire barriers using intermediate-scale multi-storey test apparatus” which came in existence in 2004 and got widely accepted to test the perimeter firestop systems for facade.

The ISMA test simulates fire exposure in a high-rise structure where, as the fire intensifies and positive pressure builds, a fire induced window breaks occurs, allowing oxygen to feed the flames. The method is meant to simulate a fire in a post-flashover condition in a compartment venting to the exterior.

The provisions of ASTM E2307 are intended to restrict the interior vertical passage of flame and hot gases from one floor to another at the location where the floor intersects the exterior wall assembly. Its use is mandated by US building codes, thereby requiring the protection of openings between a floor and an exterior wall assembly to provide the same fire performance as that required for the floor.

Test Sequence:

Cycling Test

The test method requires joint systems with movement capabilities to be cycled through the intended range of movement prior to the fire test. The movement cycling is intended to demonstrate the compatibility between the individual components of the joint system and the supporting construction. Joint systems are required to be cycled through the intended movement range 500 or 100 complete movement cycles at a minimum rate of 1, 10 or 30 cycles per minute prior to the fire test.

Fire Test

Throughout the fire test, observations are made about the fire and hot gases on the unexposed side of the perimeter fire barrier or any adjacent supporting construction.

The above certificate is from a third-party testing laboratory – UL which highlights the curtain wall system which got successfully tested as per the ASTM E2307 test and given a rating of 2 hours.

After successful completion of the above mentioned tests, following ratings are provided to the entire perimeter fire barrier system per ASTM E2307 Test:

• “F”-rating, in hours (resistance to fire spread) • “T”-rating, in hours (temperature on non-fire side) UL provides two additional ratings using same test apparatus • “integrity rating” & “insulation rating”

Test result:

It is very important to review the test certificate details and verify each detail mentioned in a test certificate and the limitations of the system passed.

Conclusion:

In Indian scenario where we have traffic issues coupled with longer fire response time, it becomes even more important for all stakeholders starting from building owners, architects, façade consultants, contractors and inspectors to take a justified approach by using only tested systems for protecting the perimeter fire openings.

Avoiding or compromising the edge of the slab opening with no or untested system means compromising with the safety of people. Perimeter fire barriers are one of the required systems from the National Building Code of India and it is an effective fire and smoke resistance compartmentation methodology. These technologies are developed and being further innovated to save lives and protect property damage.