Introduction

The concept of façade for buildings was introduced in India in 1990. Before that, high-rise structures were erected in conventional brick and mortar for external wall masonry. Mumbai is the first megacity that was exposed to the high-rise culture in the country due to land constraints. Local building bye-laws play an important role in the construction of buildings in India, however, the majority of these bye-laws have been influenced by the National Building Codes (NBC) which is the backbone of most of the building bye-laws. Before 2106, the NBC was silent about the façade construction besides the fire safety of the façade of buildings.

The use of glass façades in buildings has started gaining momentum due to its transparency and relative ease in installation and maintenance besides the aesthetic value added to the building. Modern construction practices started giving more emphasis on “Green Buildings” and then there was a constant pressure to construct green or sustainable buildings that have benefits environmentally through promoting not only the low cost of construction but also reducing the recurring expenditure by using the latest techniques of recycling, energy efficiency, and efficient use of resources. A well-designed building should meet all design objectives such as usability, aesthetics, the potential for a redesign for alternative uses, and fire safety. The purpose of writing this article is to discuss the mitigation measures for façade fires.

Fire safety of building design focused on the prevention of ignitions, smoke management, detection and warning of occupants, providing for safe egress, control and preventing rapid spread of fire. Therefore, it is essential that the façades of the building should also meet the expectation of a fire-safe building design. It’s very important that the material used for the façade system should comply with the minimum fire resistance requirement for an exterior envelope. Façade design needs to be done in a manner that doesn’t allow fire and smoke to penetrate from one compartment to another. A façade system should not fail when a fire occurs from its integrity, stability and insulation.

Based on past experience, there has been a substantial improvement in façade design to ensure exceptional structure performance in terms of energy efficacy and requirements on aesthetic appeal. These changes primarily alter the behaviour of modern façades in fire and pose a threat to structure safety and financial loss in the event of a fire. Structures with non-compliant façades pose a threat to occupant safety and may cause considerable economic loss in the event of a fire.

The Grenfell Tower fire being the latest significant incident, which occurred on the 14th of June, 2017 and resulted in at least 80 fatalities, has established how vulnerable existing façades may be to fires and how this vulnerability directly affects the safety of occupants which unfolds into catastrophic events.

1. Study Conducted in India

A study was carried out to understand the mechanisms of fire spread in façade systems, external and internal spread of fire and smoke propagation, glass-break and fire stop material behaviour in a real fire scenario, the smoke and obscuration levels, the fire spread behaviour, fire behaviour with ACP/MDF being used with glass, utility of existing smoke alarms, the behaviour of masonry wall, the impact of fire spread on structural components (beams, columns), the performance of locally available fireproofing material (cement boards), and ambient conditions in adjacent compartments during a fire.

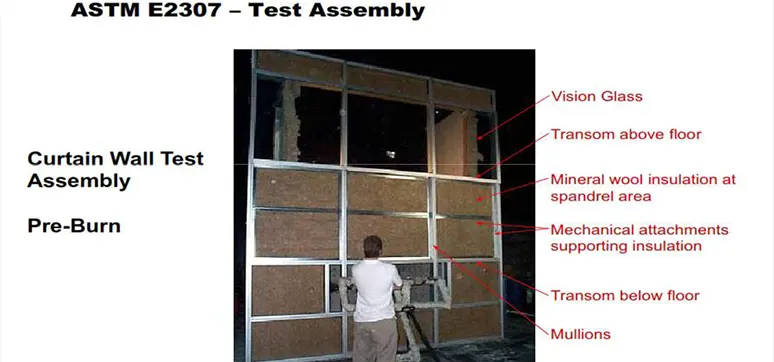

The goal of the study was to emphasise the urgent need for developing performance-based codes and to align norms governing fire safety with country-specific standards. Experimental investigation of fire behaviour carried out by IIT Gandhinagar and Underwriters Laboratories on glass façade systems reveals that a gap is always provided between the curtain wall and the building to avoid crashing of glass in case of unwanted vibrations arising from passing of heavy vehicles and/or minor earthquakes and also to mitigate effects of thermal expansion. This gap is filled with appropriate fire-stop material (e.g., Rockwool). The performance of the façade as well as the fire stop material is crucial for the overall performance of the façade system.

2. Major Façade Fires

In all building façade fire cases, it is noticed that the material used in the exterior surface cladding was highly combustive and supported rapid-fire propagation. In a few of the structures where sprinklers were installed, still, external fire spread could not be averted. A few ill-famed façade fire examples are: –

3. Mechanism of Fire Spread in Façade

Conduction – Fire can spread via heat transfer of materials, such as metals, which can absorb and transfer heat and are called thermal conductors which are primarily used as a frame in the façade structures.

Convection – Ceilings trap hot air of burning materials and prevent them from moving any higher, which then causes everything to build up heat and can cause a fire to spread. If there is adequate heat, fuel and oxygen accumulation in the area other combustible materials will start igniting and fire away from the original one will start. Once this happens, the fire will quickly engulf a whole room in seconds. This phenomenon is also observed in façade fires.

Radiation – A high-intensity fire will give off more heat. Heat can be transferred through electromagnetic waves just like Sun. There is every possibility for the fire to spread through this mechanism to the building structures nearby.

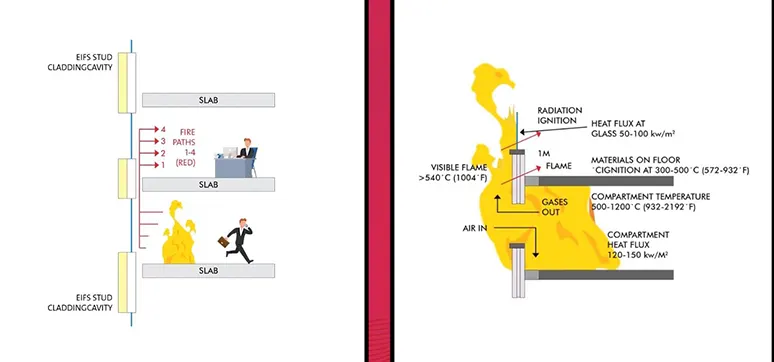

The Chimney Effect – is where heated surfaces create thermal zones that include upward air movement, which in turn sucks hot gases and flames in its direction. This effect is attributed to the spread of fire upward through shafts, and also the spread of fire upward through available openings between the floor slab edge and therefore in the curtain wall. Subsequently, a need has been felt to fill the penetration through fire-stop materials.

Leapfrog effect – This effect is clear in high-rise building fires where flames blaring out through perimeter façades ultimately spread back in through the façade above and still spread vertically to upper floors. Once the heat release rate of the fire is high enough, between 50-100 kW/m2, the window of the room above the room of origin will fall out.

Flames eject from a window, breaking the window above and causing ignition on the floor above (leap-frogging), secondary interior fires and level-to-level fire spread. Heat causing degradation/ separation of non-combustible protective skin resulting in flame spread to combustible elements internal to the wall system. Hence, the façade design must prevent the leapfrog effect.

4. Mumbai Fire Brigade Initiatives

After a few fire accidents in Mumbai and India, Mumbai Fire Brigade in September 2016 has initiated the proposal to incorporate fire safety provisions for the façade buildings which is accepted and approved by the Municipal Corporation of Greater Mumbai and incorporated into the fire safety measures with the orders that the occupiers/owners of such buildings shall comply all these fire safety requirements within 120 days of the publishing of the appeal and submit compliance.

1. The smoke seal/barriers between the building wall and the façade shall be provided at every floor level in the form of non-combustible material/ vermiculate cement.

2. Glass façade blocking the area of a staircase, lift lobby and corridor shall be kept openable. If the staircase/lift lobby is pressurised the pressurisation system shall be synchronised with the glass façade window opening mechanism.

3. Minimum of 2.5% of the floor area of each compartment on each floor shall be kept openable.

4. Refuge area shall be kept open above the height of 1.20 meters from the flooring level. However, if already covered with a glass façade all the glass panels shall be openable (either left or right hinge) both from inside as well as outside.

5. Comparison of Building Code

Requirements for Fire Resistive Design of Façades

5.1) Changes in NBC

Based on the fire safety adopted by the Mumbai Fire Brigade and the NBC has adopted the following in 2016:

1. The glazing shall be by Part 6. Structural Design, Section 8 Glass and Glazing. The entire glazing assembly shall be rated to that type of construction “Fire Resistance Ratings of Structural and Non-Structural Elements” of NBC. This shall be applicable along with other provisions of this Part relating to respective uses as specified therein. The use of glass shall not be permitted for enclosures of exits and exit passageways.

2. Glass façade shall be in accordance with the following:

For fully sprinklered buildings having fire separation of 9 m or more, tempered glass in a non-combustible assembly, with the ability to hold the glass in place, shall be provided. It shall be ensured that sprinklers are located within 600 mm of the glass façade providing full coverage to the glass.

• All gaps between floor slabs and façade assembly shall be sealed at all levels by approved fire-resistant sealant material of equal fire rating as that of the floor slab to prevent fire and smoke propagation from one floor to another.

• Openable panels shall be provided on each floor and shall be spaced not more than 10 m apart and measured along the external wall from centre-to-centre of the access openings. Such openings shall be operable at a height between 1.2 m and 1.5 m from the floor and shall be in the form of openable panels (fire access panels) of size not less than 1 000 mm × 1 000 mm opening outwards. The wordings, “FIRE OPENABLE PANEL, OPEN IN CASE OF FIRE, DO NOT OBSTRUCT” of at least 25 mm letter height shall be marked on the internal side. Such panels shall be suitably distributed on each floor based on occupant concentration. These shall not be limited to cubicle areas and shall be also located in common areas/corridors to facilitate access by the building occupants and fire personnel for smoke exhaust in times of distress.

3. Surface Interior Finishes:

• The use of combustible surface finishes on walls (including the façade of the building) and ceilings affects the safety of the occupants of a building. Such finishes tend to spread the fire and even though the structural elements may be adequately fire-resistant, danger to life may result. It is, therefore, essential to have adequate precautions to minimise the spread of flame on walls, façades of buildings and ceiling surfaces. The finishing materials used for various surfaces and decor shall be such that they shall not generate toxic smoke/fumes.

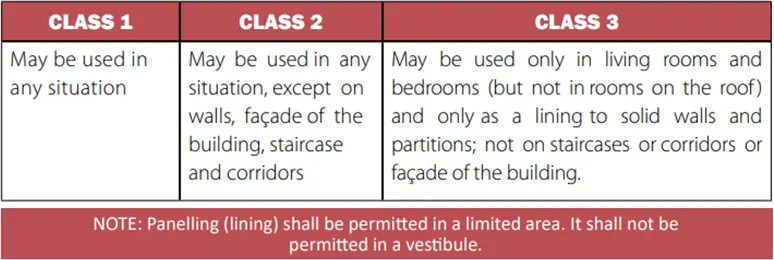

• The susceptibility of various types of wall surfaces to fire is determined in terms of the rate of spread of flame. Based on the rate of spread of flame, surfacing material shall be considered divided into four classes as follows:

1. Class 1 Surfaces of very low flame spread.

2. Class 2 Surfaces of low flame spread.

3. Class 3 Surfaces of medium flame spread.

4. Class 4 Surfaces of rapid flame spread.

• The uses for which surface materials falling into various classes shall be adopted in building construction are given below:

• Materials of Class 4 which include untreated wood fibre boards may be used with due fire-retardant treatment as ceiling lining, provided the ceiling is at least, 2.4 m from the top surface of the floor below, and the wall surfaces conform to the requirements of class 4 materials shall not be used in kitchens, corridors and staircases. Some materials contain bitumen and, in addition to the risk of spread of fire, emit dense smoke on burning; such materials shall be excluded from use under these conditions and shall also not be used for the construction of ceilings where the plenum is used for return air in air-conditioned buildings.

• When frames, walls, partitions or floors are lined with combustible materials, the surfaces on both sides of the materials shall conform to the appropriate class because there is considerable danger from fire starting and rapidly spreading within the concealed cavity unknown to the occupants whose escape may be hampered thereby. For detailed information on materials and details of construction with their fire-resistance rating, reference may be made to good practice.

4. Part- 6 Section 8.2.1 of NBC

i) Performance Criteria

The performance criteria to be satisfied by the glazing system are structural stability and safety, energy efficiency (performance), visual comfort (light transmittance and reflection), fire protection (ability to resist/ withstand fire), sound insulation, air infiltration (wind pressure, stack pressure, fan pressure), and water penetration (static, dynamic and cyclic pressures).

ii) Movements

The glazing system (and its framing elements) shall be able to accommodate the movements caused due to wind loads, seismic loads, live loads, dead load deflection, thermal expansion and contraction of members, slab deflection, etc.

iii) Types of Structural Frame Materials

For the framed/semi-framed systems, materials such as aluminium, stainless steel, uPVC and timber, which are commonly employed are listed hereunder.

• Aluminium Alloy- is commonly used for higher strength.

• Stainless Steel- is employed for its mechanical properties as they are highly corrosion resistant for all normal exposures.

• uPVC- A relatively flexible material, PVC which is internally reinforced with steel or aluminium to give it the required strength and stiffness may also be used.

• Timber- Timber frames are relatively stiff and are adopted for their inherent thermal insulation property, lightweight and improved sound insulation.

5.2) National Construction Code Australia

Standards Australia has developed an additional Australian Standard (AS 5113- 2016 (Standards Australia 2016) on “Fire propagation testing and classification of external walls of buildings”, that offers procedures for the fire propagation testing and classification of external walls of buildings conferring on their tendency to limit the spread of fire via the external wall and between adjacent buildings.

This standard has been developed based on international practice and is consistent with the testing criteria prescribed in ISO 13785 (International Organisation for Standardisation 2002) and BS 8414 (British Standard Institute 2015) Parts 1 and 2. National Construction Code (NCC) Australia expects a certain performance requirement from the external cladding of a building (The Australian Building Codes Board 2016). There are two paths to meet the specified performance criteria; deemed-to-satisfy solution and performance solution. Where a deemed-to-satisfy solution is proposed, performance requirements which are categorised in the order from CP1 to CP9 should be satisfied depending on the type of construction.

Where a performance solution is proposed, it requires a report from a qualified fire engineer. The report should be based on full-scale façade tests carried out in accordance with BS 8414 (British Standard Institute 2015), ISO 13785 (International Organisation for Standardisation 2002), and NFPA 285 (National fire protection association 2012), or any equivalent international standard. Standards Australia has released AS 5113, a full-scale façade test based on BS 8414 and ISO 13785.

When cladding is part of the external wall, it should be non-combustible for buildings that have more than 3 storeys (The Australian Building Codes Board 2016). The combustibility of the material should be determined by testing in accordance with AS 1530. For laminated products, the test should be carried out with individual layers and a stack of laminates similar to the end-use condition. NCC prescribes the non-combustible requirements for bonded laminated elements as follows (Australian Building Codes Board 2016;

The Australian Building Codes Board 2016):

• Each laminate is non-combustible in accordance with AS 1530

• Each adhesive layer does not exceed 1 mm in thickness; and

• The total thickness of the adhesive layers does not exceed 2 mm; and

• The Spread-of-Flame Index and the Smoke-Developed Index of the laminated material as a whole do not exceed 0 and 3 respectively in accordance with AS 1530.

However, if one or more laminates are combustible, it violates non-combustibility requirements and therefore cannot be used as part of a deemed-to-satisfy solution where a non-combustible material is required in the façade (Australian Building Codes Board 2016).

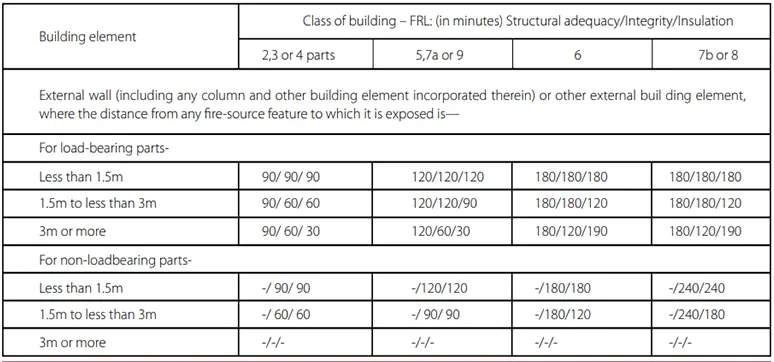

In addition to external claddings, other elements such as framing, spandrels, insulation and internal lining (e.g., plasterboard) are often considered as part of an external wall. The external wall can be load-bearing or non-load bearing. Depending on the load-bearing condition and the distance from the fire source, NCC also specifies fire resistance level (FRL) in minutes for buildings of more than 3 levels for the three main performance criteria; structural adequacy, integrity and insulation (The Australian Building Codes Board 2016) (see Table).

When cladding is considered to be an attachment to the external wall, combustible material can be used, given that it satisfies certain conditions of not impairing the external wall fire resistance. The material should meet the fire hazard properties. The combustible cladding should not be located near or directly above an exit and it should not constitute an undue risk of fire spread via the façade of the building. The attachment should also meet the required FRL for that construction type (refer to Table above).

However, NCC also specifies exceptions for combustible materials or containing combustible components such as fibres. These exclusions can be plasterboard, perforated gypsum lath with a normal paper finish, fibrous-plaster sheet, fibre-reinforced cement sheeting and pre-finished metal sheeting having a combustible surface finish not exceeding 1 mm thickness and where the Spread-of Flame Index of the product is not greater than 0.

5.3) Approved Document B – UK

Approved Document B (ADB) (Department of Communities and Local Government 2010) is used as the guideline under building regulations to determine fire safety. While ADB specifies certain conditions to be satisfied for the cladding to be fire-resistive, it also gives provision to alternate means of compliance by testing according to British Standard 8414 and assessment in accordance with Centre for Window and Cladding Technology BR 135 (2017). Fire-resistance of the wall should be dealt with EN 1364-4 (European Committee for Standardisation 2014). As this article is more focused on the façade fire, the guidelines that apply primarily to façades will be discussed in detail.

If the building contains a floor more than 18m above ground level, the following set of conditions applies for the installation of façades.

• Any insulation product, filler material (not including gaskets, sealants and similar) etc. used in the external wall construction should be of limited combustibility and meet the requirement of Euro class A2 materials;

• External surface above 18m should be Class B;

• External surface below 18m can be Class C provided distance from boundary exceeds 1m.

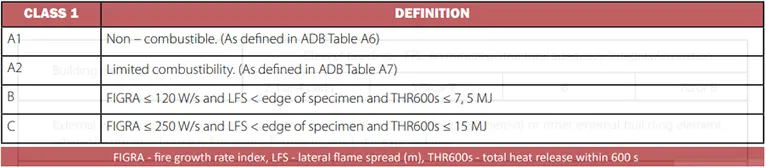

Combustibility of materials is classified in accordance with EN 13501-1 (European Committee for Standardisation 2009) as A1, A2, B, C, D, E and F with A1 being the highest performance and F being the lowest. Table- Combustibility class of materials used in ADB (Centre for Window and Cladding Technology 2017; Department of Communities and Local Government 2010).

According to guidelines (Centre for Window and Cladding Technology 2017; Department of Communities and Local Government 2010), if the building does not contain a floor more than 18m above ground and the façade is within 1mtr of the boundary, the external surface should be of Class B. When the façade is more than 1mtr away from the boundary for buildings more than one storey and shorter than 18m, Class C material can be used for the external surface. In any of the above cases, if the façade contains cavities, cavity barriers should be provided in accordance with the Centre for Window and Cladding Technology.

5.4) International Building Code – US

International Building Code (IBC) was adopted by the United States as the document to form building regulations. Façades should comply with the material fire resistance rating specified by the code depending on the construction type or the assembly of façade should pass the test titled NFPA 285– Standard fire test method for evaluation of fire propagation characteristics of exterior non-load bearing wall assemblies containing combustible components.

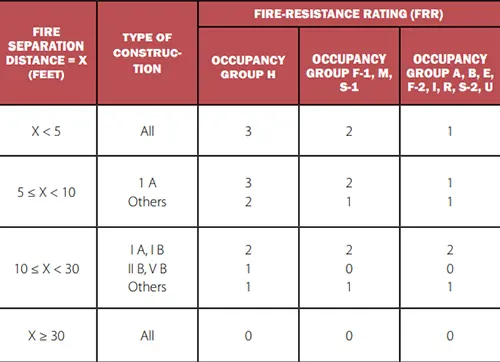

Following construction, types are defined in IBC depending on the combustibility of the material used in building components. Fire-resistance rating requirement varies for different construction types as shown in Table.

• Type I and II – Building elements listed in Table 601 (Primary structural frame; exterior and interior bearing walls, non-bearing walls and partitions; floor and roof ) are of non-combustible material, except as permitted in section 603 and elsewhere in code

• Type III – Exterior walls are of non-combustible material and the interior is of any material permitted by the code

• Type IV (Heavy Timber, HT) – Exterior walls are of non-combustible material and the interior building elements are of solid or laminated wood without concealed spaces

• Type V – Structural elements, exterior walls and interior walls are of any materials permitted by this code

Building such as assembly (A), business (B), educational (E), factory and industrial (F & I), mercantile (M), storage (S), High-hazard (H) and so on depending on the fire separation distance and occupancy level, following fire-resisting rating is specified for non-load bearing cladding on different construction types mentioned earlier. When the fire separation distance is more than 30 feet (9.2m) there is no requirement on the façade’s fire rating.

IBC also relaxes these limits for fire retarded treated wood used in the construction of exterior walls. The tests are also required to establish the vertical and lateral flame propagation for exterior walls that contain combustible water-resistive barriers in structures of type I, II, III or IV construction that are taller than 12 meters.

Fire safety requirements used materials in façades such as metal composite materials (MCM), exterior insulation and finish systems (EIFS), high-pressure decorative exterior grade compact laminates (HPL), foam plastic insulation and fibre-reinforced polymer are specified in detail. The requirement for MCM is a flame spread index not more than 25 and a smoke-developed index not more than 250 is specified when tested in accordance with ASTM 84. For HPL those indexes are 75 and 450. The fire spread characteristics of foam plastic insulation are determined after doing the test in accordance with NFPA 285.

Conclusion

The use of glass façades will further increase in the near future as more and more emphasis has been given to green buildings. However, excessive use of unrated glass façades cannot be allowed due to the inherent fire risk associated with the systems. It is, therefore, necessary to observe the following mitigation measures to prevent façade fires in future:

1. Use of fire-rated glass and associated accessories in the buildings.

2. Design of the façade should not encourage the leapfrog effect.

3. Setback area given in the building by-laws should be strictly adhered to avoid the mechanism of spreading fire to the adjoining structures.

4. The glass break behaviour should not affect the dwellers and rescuers.

5. Sealing of penetrations with suitable fire stop material to prevent smoke and fire movement which cause flashovers/backdraft.

6. Use of curtain-type sprinkler in the vicinity of the glass which will act as a barrier and will keep the glass away from the source of fire

7. Spandrel area depth and insulation are important. 8. Testing of Lamination used in the glass façade as per AS 1530.

References-

• Electronic Journal of Structural Engineering 16(1) 2016- Performance of modern building façades in fire: a comprehensive review.

• Mechanism of fire spread on façades and the new Technical Report of EOTA “Large-scale fire performance testing of external wall cladding systems”- Ingolf Kotthoff and Jan Riemesch-Speer.

• Façade systems and fire Gaurav Srivastava Associate Professor Civil Engineering, IIT Gandhinagar.

• Municipal Corporation of Greater Mumbai- Mumbai Fire Brigade, Ref-MGC/F/779. Sub-Fire Safety Requirements for Existing Glass Façade Buildings

• National Building Code of India 2016