The senseless loss of many lives during the Grenfell Tower incident in June 2017 caught the attention of the media and of the public at large. We all have, in our heads, images of the raging fire progressively engulfing the entire tower, flames rising high and black smoke billowing. Although this particular event was spectacular and caused the loss of many lives, it was by no means the first of its kind.

In fact, it really was one more incident in a long string of fires around the world, particularly in Asia and the Middle East, involving the exterior envelope of tall buildings. In many of these incidents, the initiating event was either an electrical short-circuit or a discarded cigarette butt. However, these seemingly harmless incidents would not have had such extensive consequences, had the cladding material been selected sensibly, and the building envelope designed and built correctly.

Regional Regulations On Fire Performance Of Facades

Local practices and regulations regarding the fire performance of building envelopes vary widely from one country to the next. These determine the materials that may or may not be used on building façades, and dictate as well certain crucial aspects of façade, such as the need for firemen access panels, smoke extraction vents, fire separation across different floors or compartments, fire-rating of façade materials, and much more.

It should be noted that in the aftermath of the Grenfell Tower incident and subsequent ones, some of the fire regulations are being reviewed by local authorities, with a view of amending or tightening the regulations related to the performance of building façades. Therefore, the local fire legislations are likely to evolve in the coming months. In particular, the Singapore Fire Code has been updated in late 2018, to incorporate the recommendations of the Cladding Regulatory Regime Review Advisory Panel. These recommendations aim at improving the current certification regime for composite cladding products.

Fire Performance And Testing Of Cladding Materials

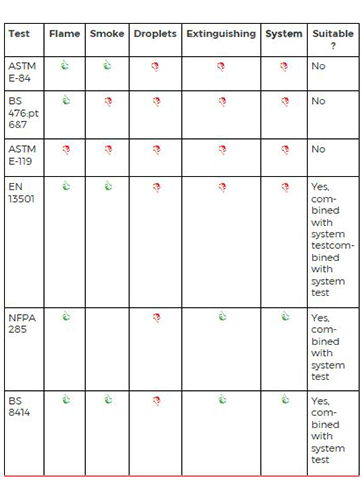

A variety of tests exist and are implemented, in order to establish the fire performance of various building envelope materials and systems. These tests may be large-scale (whole system test) such as the NFPA 285 or BS 8414, or small-scale (material performance test) like BS 476 or EN 13501, and may consider a variety of aspects, including spread-of-flame, smoke production, production of flaming droplets, and more.

Standards institutions are actively working on improving existing standards as well as developing new ones where the current standards fall short of current industry needs. For instance, BS 8414 is a two-part standard that describes methods for testing the cladding in two different setups, and which has been ported to standards in countries such as Australia and the UAE. However, there was a need to develop a new standard to comprehensively interpret the results from this test. BSI has thus written BS 9414 (“Fire performance of external cladding systems. The application of results from BS 8414-1 and BS 8414-2 tests”), which has just been published in September 2019.

Detailing Of Curtain Walls

Although composite panels have become the focus of the industry in the past couple of years, with some developers and architects deciding to ban this product from their projects, their negative reputation is ill-deserved. Composite panels, when properly selected and detailed, can be perfectly safe.

Similarly, in the case of Grenfell Tower, the composite cladding, although of a type that should not have been used (it had a polyethylene core), was apparently only a small contributor to the final outcome. According to the investigation report, the thick, flammable insulation materials used, combined with incorrect detailing of the cladding system, played a larger role in this incident.

Regulations vary widely from country to country. Generally, a horizontal fire separation in the cavity between the face of the building structure and the back of a curtain wall is required. This should typically have a fire resistance of two hours. However, the manner in which this fire-stop is achieved is often incorrect, resulting in the premature dislodgement of the fire stop in the event of a fire, thereby resulting in the free passage of flames and smoke to the floor above.

Similarly, some jurisdictions require the inclusion of fire separation within cladding cavities, while other authorities do not require such an implementation. The absence of fire breaks in cladding cavities can result in the rapid spread of flames to all areas and all levels of a building, as a result of the chimney effect. Recent changes to the regulation in Singapore, for instance, require the addition of fire breaks under certain circumstances. This is particularly relevant for high-rise buildings, where incorrect detailing of the façade could cause the fire to spread upward in an uncontrolled manner.

Summary

It is encouraging to see that authorities and building practitioners alike are increasingly paying greater attention to the fire performance of building envelopes. There is hope that these will result in improvements in regulatory frameworks in many countries, as well as increased awareness through education and seminars, all of which will contribute to making our buildings safer when it comes to fire incidents.