The understanding of façades within the Fire and Life Safety (FLS) industry is evolving and, in fact, we can see clear progress in the overall “design” of exterior wall systems in relation to fire risks. In our region, particularly in the GCC, the start of the fire / façade evolution took place immediately after The Address Fire in Dubai on New Year’s Eve 2016. The unfortunate incident made the news worldwide since it was captured on the live broadcasting of Dubai Mall New Year Fireworks. This added significant pressure on the industry to come up with urgent solutions to prevent such incidents from happening again. This pressure by the various Authorities Having Jurisdiction over the industry experts, committees and consultant firms led to the issuance of the updated UAE Fire and Life Safety Code in The Address Fire, Dubai 2018, which has a comprehensive section dedicated to the safe design of façade systems (Chapter 1, Section 4: Façade & Exterior Wall Covering Systems), taking the best practice approaches from both American and European international codes and standards. In the same region, the Saudi Building Code-SBC 201, and Saudi Fire Code-SBC 801 (which are largely based on the International Building Code and International Fire Code, respectively) were published in the same year (2018), spearheading a new era of construction management in KSA and driving more countries in the region to be part of the overall construction evolution.

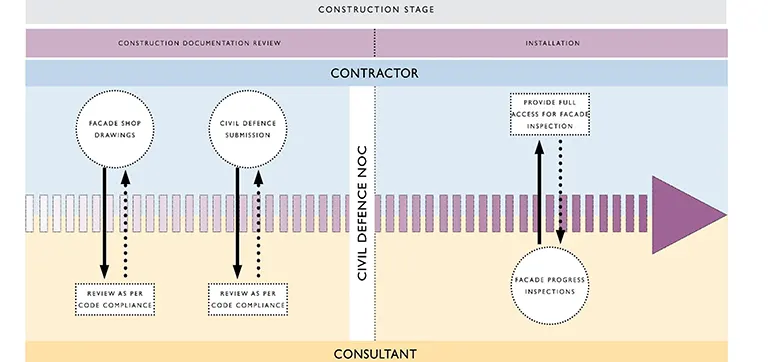

The UAE FLS Code 2018, Chapter 1, Section 4, includes a list of requirements applicable to design, materials and Civil Defence approval. In summary, Civil Defence approval can be obtained by following the ‘Ten Point Approach’, which is intended to mitigate the risk of façade fires. This approach can be summarised as follows: 1. The core of the façade material shall be tested in exposed form as per the test requirements of the code. 2. The façade panel as a product shall be tested as per the test requirements of the code. 3. The façade system shall be tested as a wall assembly or shall be a listed system (previously tested) as per the requirements of the code. 4. Curtainwall’s perimeter joints and fire stopping shall be a listed system. 5. Cavity fire barriers shall be provided in concealed cavities between the façade and the primary substrate, at every slab. 6. Fire barriers shall be provided vertically between compartments and different exterior wall systems. 7. Exterior sprinklers should be considered for the balconies having combustible materials. This is currently on hold by AHJ due to the uncertainty of external sprinkler effectiveness in such applications. 8. Consultants shall have competent and qualified façade specialists in-house or shall hire a Civil Defence approved consultant (House of Expertise) who has experience and expertise in the design, selection and construction supervision of facade systems. 9. Façade contractors and fabricators shall be approved by Civil Defence, with a valid Civil Defence license. 10. Façades shall be inspected throughout the installation process and certified by Façade Fire Experts or Civil Defence approved House of Expertise. It can be said that the above points are implemented successfully in most new projects in UAE, apart from Item 7, which is currently under review by Civil Defence, and Item 9, which requires significant “legal” and “commercial” coordination with government authorities other than Civil Defence. Compliant façade design and installation in the UAE are formally recognised by Civil Defence through the award of Façade No Objection Certificates (NoC). This process starts during the initial Civil Defence approval of the design drawings and continues to the construction stage where five site inspections are conducted by façade fire experts and/ or house of expertise. It is the main consultant’s responsibility to ensure that the façade NoC is obtained prior to the installation and that compliant façade installation is carried out and suitably documented with inspection certificates. Within the Saudi Building Code (SBC 201, 2018), the overall applicable requirements for exterior walls and roofing assemblies are detailed in Chapters 14 and 15. These chapters primarily set out to: • Identify the performance targets in relation to fire resistance and fire propagation; • Classify the minimum required flammability based on building height and construction type • Detail the requirements for metal composite materials, external insulation & finish systems (EIFS) and high-pressure decorative exterior compact laminates (HPL).

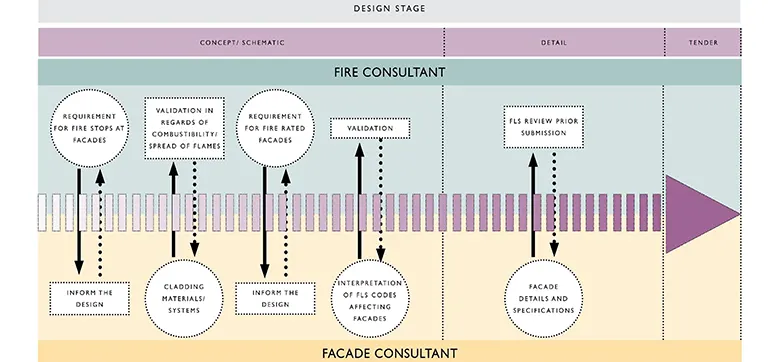

Ideal fire/façade coordination at design stage Moreover, SBC 201 includes six chapters that detail the requirements for specific materials that are typically used on external wall systems, namely: • Aluminium – Chapter 20 • Steel – Chapter 22 • Wood – Chapter 23 • Glass and Glazing – Chapter 24 • Gypsum Boards, Gypsum Panel Products and Plaster – Chapter 25 • Plastics – Chapter 26 Since SBC heavily relies on IBC as an international code reference, the material’s fire performance classification is assessed based on flammability (ASTM E84), heat radiation and fire propagation (NFPA 285). On the other hand, fire performance classifications in the UAE FLS Code 2018 are also based on combustibility and self-ignition temperatures, in addition to the ones adopted in SBC. Despite the differences, both codes are aligned with the requirements of exterior wall fire resistance classification. However, they adopt different approaches in relation to cavity barriers (fire-blocking as per SBC terminology). SBC codes are flexible on the material type of cavity barriers, allowing for eight different materials to be used, including 13mm gypsum board, 6mm cement-based board or 50mm nominal lumber (refer to SBC 201, Section 718.2.1, Page 217 for the full list of materials). However, Civil Defence in the UAE requires all cavity barriers to be listed and approved materials, as well to be part of full assembly tested in accordance with NFPA 285 or BS 8414. In general, we can confidently say that both UAE FLS Code – 2018 and SBC 201 & 801 – 2018 can be considered as the main regional reference for facade design in relation to fire safety, to minimise the likelihood of incidents like The Address fire from happening again. Following the successful Façade NoC initiative by UAE Civil Defence in 2018, which enforced Clients, Consultants and Contractors to carefully follow the code requirements throughout the design and construction stages, we can expect other countries within the region to follow similar initiatives. We also hope for more workshops, hosted by the relevant local authorities that gather the industry experts in one room to share their experience, thoughts and lessons learnt with the aim to push the industry towards better and safer façade design.

In the world of façade fire safety, the obligation of safe façade design will not be accomplished without assessing “ALL” of the following fire aspects, where applicable, irrespective of the code requirements: • Fire resistance • Combustibility • Flammability • Self-ignition temperature • Heat radiation • External firestopping and barriers • Fire propagation As a closing statement, I would like to emphasise that it is the fire consultant’s “ethical” responsibility to design safe buildings in relation to fire safety and not only comply with the minimum code requirements, which do not guarantee a safe design, especially in more complex buildings. It is our obligation to highlight to architects, consultants and clients any identified risks beyond the minimum code requirements, in order to achieve safe buildings for us and for many future generations to live in.