Hardware Fittings are Getting Sleeker and Minimalistic

By: Rajan Aggarwal, Ozone Group

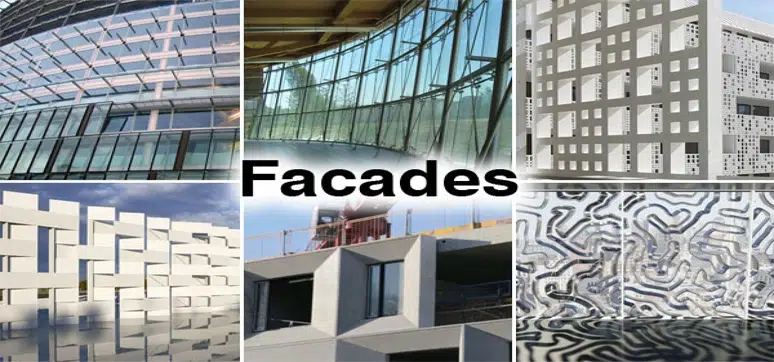

WFM: What are the criteria for the selection of Architectural hardware for facades and fenestrations?

Rajan Aggarwal (RA): With more number of design & options available, right selection of hardware for the windows, doors and facades has become very important. While selecting the hardware, functional need and safety should be given priority and they shouldn’t get superseded by aesthetics requirements. One should check the certification for number of usage cycles, weight and load factors at the time of selection of hardware. After taking care the above, one should select the design as per the need of design of the façade perceived by the designer.

Main concept with aesthetic requirements of façade design is generally given by the architect. This needs to be further developed by using various types of hardware. The type of hardware is selected as per the structural requirements of the façade, for example structural load, wind pressure etc. Grade of hardware is selected as per weather conditions of region/location.

Ozone offers a wide range of façade spider fittings along with allied accessories in number of design options suiting to varied needs. These spider fittings and hardware are made available in stainless steel grade 316 & 304 for different weather conditions and in PSS & SSS finishes for varied aesthetic needs.

WFM: Please elaborate on trends in architectural hardware products. What are the common materials preferred for architectural hardware?

Rajan Aggarwal (RA): What’s visible is aesthetic and what’s functional is technology, and today’s trend is that both should come in a single package. The hardware industry has also advanced with time and is able to deliver as per the modern-day functional necessities & aesthetic needs. It has started giving various design options of a type of fitting delivering the same function.

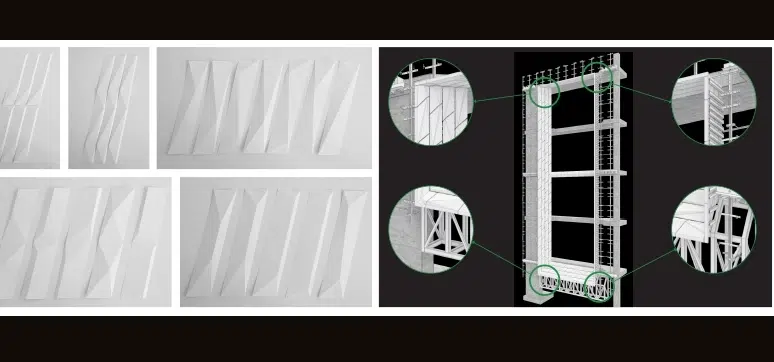

Hardware fittings are getting sleeker and minimalistic, with lesser use of material and better design techniques. It is also getting leveraged by better production technology and hence durability. Therefore we keep on innovating newer designs to be able to offer choices to clients for achieving better aesthetics yet meeting escalated functional needs. The latest among these are Metal Sheet Spiders from Ozone which are offered in designs inspired by nature such as petals, dew drops, butterflies & solar series of façade spider fittings.

WFM: Please tell us about the latest technologies in hardware products.

Rajan Aggarwal (RA): New technologies in investment casting and CNC machining have increased the speed and quality of the hardware, and also enable the brands to offer numerous design options with customization. Various kind of software helps in faster designing and converting your imagination into reality. You can further get the 3D model by a 3D printer to give you a real view of the final product. All these were very time-consuming & expensive earlier. Automatic conveyors and the availability of special-purpose machines have increased the speed and quality of the final delivered product. Global connectivity due to the internet has further helped users to use the spare machine capacity available at various manufacturers. We are equipped with the most advanced CNC machines, tools & software enabling it to deliver hardware products as per international standards of quality & safety.

WFM: Please give us a brief note on your latest façade /fenestration hardware product.

RA: Ozone introduced Rhombus – Glass Clamp Patch Fitting, a point fixed facade fitting specially designed for double glass glazing (DGU) facade projects yet it can be used for single glass glazing too. With this Glass Clamp Patch Fitting, no need to have cut-outs on the glass for fixing, which makes it suitable for DGU facades and also saves installation time & cost. It bolts & holds the glass panes at their corners, providing strength to the glass, and meeting all structural requirements such as dead weight of the glass, wind load & differential expansion due to temperature fluctuations. This newly developed product is crafted in a rhombus shape adding diamond-like geometrical touch to the façades and is available in stainless steel grade 304 & 316; it is tested for structural integrity, safety and stability. Another latest offering from façade fittings range of Ozone is Metal Sheet Spider fittings. These are manufactured using investment casting techniques enabling it to offer numerous design options such as petal, butterfly, dew drop & solar spider fittings.

WFM: Tell us about the future of the Architecture Hardware industry.

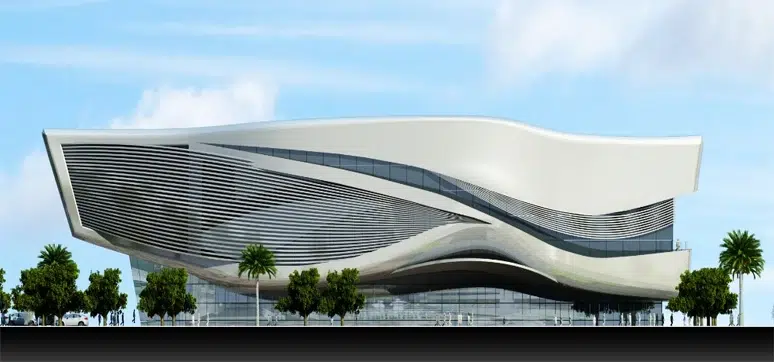

RA: Glass, Aluminum and SS hardware are the main products/fittings of facades & Fenestrations. Indian façade industry has upgraded a lot from 2000 to 2016 in terms of shape, size, design & functionality. Further it will be getting more technical in terms of energy conservation, better insulation, solar façades etc.; façade shapes are going to be more versatile and organic in nature. In future, facades will not just conserve energy, indeed they are going to contribute to energy generation.

The façade will be easy to maintain, and fast to assemble at the site with modular in nature design & construction without negotiating on aesthetics & functionality. With all these expected changes, hardware will also have to change, innovate and become more versatile as per changing trends. The new grade of stainless steel with better strength will come into play in making hardware fittings. The use of software in designing and ST analysis is expected to integrate and help to produce productive solutions. Foreseeing these upcoming trends, Ozone’s research, design & development team is empowering itself with thorough knowledge of the subject so that in times to come it can match the standards.

Top Stories

Façade Systems Market Size is Estimated to Reach USD 398.8 Billion by 2029

By: Abdul | April 16, 2024

Improving Sustainability Alongside Fire Safety – Can We Deliver?

By: Abdul | April 16, 2024

Foster + Partners Wins the Competition the New Xicen Science & Technology Centre

By: Abdul | April 9, 2024

A Symbol of Architectural Brilliance & Cultural Significance

By: Abdul | April 8, 2024