Knauf Insulation has more than 40 years of experience in the insulation industry. How has been its journey so far?

Knauf started operating in the insulation industry upon the acquisition of the first Fiber Glass plant in Shelbyville, USA, back in 1978. In 2002, after years of consistent progress and growth, Knauf Insulation was founded and in 2013 the company expanded its presence to the Middle East, operating from our local plant in Abu Dhabi. Since its establishment, the company has been an essential part of the regional industrial fabric and a major partner to some of the most prestigious developers. We are delighted to have contributed with our energy-efficient solutions to landmark projects across the GCC but also to India, Pakistan, Sri Lanka, Africa, and East Asia. Decades of hard work and consistent high quality have placed Knauf Insulation as a market leader and a name that is synonym with dependability.

To drive change towards a more sustainable industry, we have developed ECOSE® Technology, our unique bio-based binder used in the manufacture of all our Glass Mineral Wool products. Our Mineral Wool made with ECOSE® Technology contains no added formaldehyde or phenol, meaning that our insulation generates very low levels of dust, increasing the comfort of those handling it. It is made from natural raw materials that are rapidly renewable and is 70% less energy-intensive to manufacture than traditional binders, so it is kinder to the environment too.

Knauf Insulation was awarded the first Indoor Air Comfort Gold Standard certificate in 2010 from Eurofins Scientific for its Mineral Wool products with ECOSE® Technology, completed as part of the Eurofins Indoor Air Comfort Gold standard testing and certification. Knauf Insulation Mineral Wool with ECOSE Technology is certified as an ‘outstanding material’ according to the VOC (Volatile Organic Compounds) indoor air quality emissions regulations and has been excluded from any ‘hazard’ classification under standards related to the classification and labeling of chemicals.

What products and solutions do you offer? Please tell us about your fire safety products?

Knauf Insulation is the market leader in thermal, acoustic, and fire-safe Mineral Wool solutions. We offer a wide range of products designed to meet the most demanding requirements, from building regulations authorities to the design needs we receive from developers, architects, and consultants. All our products are non-combustible, release no odours, no toxic fumes, and do not contribute to fire development at any stage. Our Glass Mineral Wool range is unparalleled in thermal, fire, and acoustic performance with products developed for interior partitions, façades, roofing, soffits, pre-engineered buildings, and HVAC systems.

Fire safety is a priority for us. We have conducted several third-party tests on our products, individually and as part of system assemblies, on applications where fire performance is fundamental such as is the case of façades. All our products are certified by Fire Safety Authorities across the region.

Could you please tell us about some of your clients or the projects in which your products have been used?

Knauf Insulation is proud to have been a partner in some of the most iconic projects throughout the world. In our region, our team works closely with consultants, architects, and developers to help turn visions into reality. Some of these success stories include the Pipe Insulation at SeaWorld Abu Dhabi, the first park outside USA and home to the UAE’s first dedicated marine research providing world-class facilities to support regional and global conservation efforts. The nature of the project involved a need for highly efficient thermal insulation for chilled water piping coupled with fire safety.

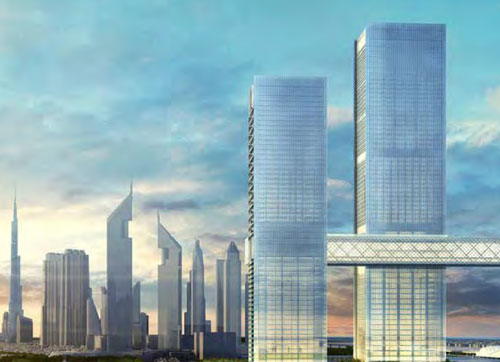

Knauf Insulation also partnered up with the developers and contractors of the outstanding One Za’abeel in Dubai, providing thermal and acoustic solutions for various applications. One of these applications involved the development of customized products able to perform under semi-exposed conditions. The façade insulation at Royal Atlantis was trusted to Knauf Insulation, where solutions depending on the energy efficiency requirements were designed and delivered.

The list of successful contributions ranges from Airport projects including the Abu Dhabi Airport or the King Abdulaziz Airport in KSA, Landmarks including the Coca-Cola Arena and the Louvre Museum, Education projects such as the Khalifa University and the Abu Dhabi Future Schools, Shopping Malls as the Yas Mall or the Meraas Outlet Village, Mixed-use building such as the City Walk, Downtown Views, and many others.

Could you please tell us about your manufacturing facility and capacity?

Knauf Insulation is present in more than 40 countries and has 27 manufacturing sites in 15 countries. In the Middle East, our manufacturing unit located in Abu Dhabi is a dedicated plant to produce Glass Mineral Wool products. At the heart of the facility, furnaces and melters provide a continuous flow of molten glass which is transported to high-rotational speed spinners producing microscopic thin glass fibers. Curing ovens ensure the bond between the fibers and the thermosetting resin binder is long-lasting, after which the products are dimensioned as needed and finally packaged, ready for the next shipment to a job site, logistic hubs, or any other location. The facility is capable of more than 7M sqm annually, with planned upgrades upcoming.

What are the advantages Knauf Insulation has over its competitors?

Today the market demands are significantly different than just a few years back, and we have been seeing several products flooding the market from all over the world, trying to solve the same problems. Striking a balance between competitive pricing and the right solution is always an interesting challenge. Within the current market conditions, Knauf Insulation has been able to find a competitive edge over its competitors thanks to the nature of our own company values.

Taking care of what really matters drives us to be as geographically close to our customers and our communities as possible. That way we have an immediate response to support queries and we are able to do it personally. Manufacturing locally and controlling the supply chain in its entirety enables quick lead times and deliveries during construction stages while reducing our carbon footprint. Knauf Insulation has dedicated technical and commercial teams to assist our partners during concept, design, and installation periods, reducing time lost in the search for various solution providers.

Knauf Insulation’s commitment to sustainability pushes us to develop and deliver solutions that help developers achieve the highest scores on green building rating schemes including LEED, BREEAM, Estidama, and Al Sa’fat. Lastly, as a UAE-based company, we contribute to the industrial sector development and local economy, promoting growth and a better future for the region we live in.

What are the major opportunities for your business in the Middle East?

The insulation business has significantly developed in the last couple of decades. We have seen a plethora of petroleum-based insulation products flooding the market and gaining share in the process, oftentimes where fire safety concerns and standards were not as high as today. Renovation, a segment not so typically seen locally, is expected to grow in the upcoming years, and the advent of energy efficiency codes (Local Green Building Codes, LEED, and BREEAM rating schemes) throughout the region demand fire safe thermal insulation where it was not previously installed or where regulations were lenient.

At Knauf Insulation, we aim to deliver net-zero embodied carbon products and solutions, have set a goal of reducing the embodied carbon of our products by 2025 by 15% compared to 2019. As net-zero carbon emissions are becoming an increasing concern of building designers, including façade design specialists, we help architects and engineers select optimal solutions that meet the required thermal transmittance values while reducing the carbon footprint. Glass Mineral Wool with ECOSE Technology, as a lightweight product that is 70% less energy-intensive to manufacture, is the ideal solution for high acoustic and thermal performing building envelopes.

Dubai’s EXPO 2020, with more than 25 million worldwide visitors expected to attend the innovation and technological showcase, is poised to boost the local economy and capture international investment, cascading to several economic sectors. The fast construction development of Saudi Arabia is captivating, with several iconic projects being launched, while just next door the FIFA World Cup will be hosted in Qatar next year, again providing several opportunities in the construction sector.

How do you see the Building and architectural market in the Middle East for your fire safety products?

The global impact of COVID-19 has been staggering, with Passive Fire Protection products also recording a decline across the globe, affecting the Middle East as well. However, the market is projected to grow above 4% in the next 7 years while the demand returns to pre-pandemic levels.

Recently, significant local fire outbreaks have raised the question of better and stricter fire safety measures. This is pushing the demand for high-quality and fire-code compliant products as the desire for taller buildings keeps rising. The increasing popularity of net-zero carbon initiatives and the green building rating schemes drive the expectations for high building performance and occupant safety. Efficient thermal envelopes, high-level air and water tightness, and fire compartmentation are building aspects that increase the necessity for more thermal insulation and proper firestop that will increase as the buildings grow taller.

Knauf Insulation offers a range of sustainable non-combustible products aligned with the latest fire and life safety codes. As an insulation market leader, we are always keeping up with the industry practices and market demands – our specialized Fire Safety team is constantly developing new and better solutions.

What are the major challenges in your industry in the region?

The pandemic had a major impact on the delivery of projects. As liquidity and capital management were prioritized, the investments were reduced across the market due to the dwindling cash flow of developers and contractors. Large public listed construction and real estate companies saw sharp declines in the rating evaluations leading to increased financing rates and risk, to the point where financing was less sustainable with new developments halted to date. The significant exodus of manpower lead to declining retail spending, a decrease in rental income due to the rising unit availability, and a reduction of rent values.

Some construction projects have been indefinitely delayed or canceled, while the rising building materials prices and inflation rates are causing supply chain bottlenecks in funded projects and reducing interest in moving projects from plan to develop. Mid-level and small-cap manufacturers and contractors have been specially targeted, with bankruptcy and company closing being a reality for the past year and a half.

Insulation, especially in this climate, is deemed fundamental. Being a local manufacturer is an asset for our partners as our production lead times and delivery costs can be significantly more competitive.

Although the outlook is not yet completely clear, with a large fully vaccinated population entering the post-pandemic era, we are seeing consumer confidence increasing, employment growth, and expectation of new construction contracts.

What do you think about the current fire safety codes for buildings in the region?

The building codes have been developed significantly in the latest iterations, adopting the best-accepted industry practices, and relying on independent certification agencies overseen by local authorities and reliable third-party experts. New regulations are being developed and we expect even stronger requisites on fire behavior of building materials.

Glass Mineral Wool, as a non-combustible material, is completely aligned with the fire codes for any application. In façades, extensive system assembly tests and individual combustibility classification tests are mandatory, but that is not the case for other building systems.

Petroleum-based products, allowed by the fire codes to be commonly used as insulation materials for applications that may include roofing and HVAC systems, do not fall under the non-combustibility classification and the usage of these products represent a fire hazard with potentially serious consequences for building occupants, facility usage and overall building performance. The current fire behavior requirements for these types of products (e.g. surface burning tests) are limited in scope, demand performance, and do not adequately mimic the real-life fire developing conditions. It is our understanding that the fire codes should be updated to better reflect that and we are developing efforts to raise this concern.

What sustainability means to you? How sustainable are your products?

Sustainability is at the heart of what we do at Knauf Insulation. Our commitment is to constantly find new ways to drive change, develop solutions that reduce the environmental impact, and care for what really matters: our people, our customers, our communities, and ultimately, our planet.

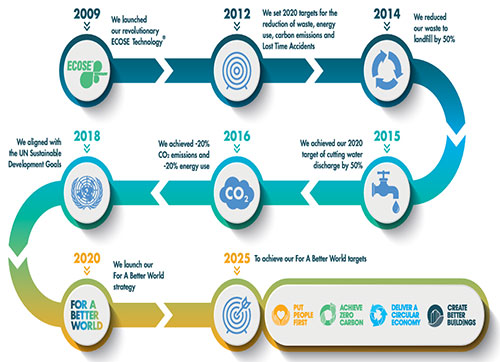

At Knauf Insulation, sustainability has always been indispensable to our long-term growth and we are proud of our achievements in the last decade, but we are now determined to be even more ambitious. In October 2020, we have launched our new sustainability strategy “For a Better World”, setting challenging concrete targets for 2025 – including decreasing accident rates by 55%, sending zero production waste to landfills, and reducing the embodied carbon of our products by 15%.

Our strategy is aligned with the Sustainable Development Goals adopted by the United Nations. Knauf Insulation is also a signatory of the UN Global Compact which is a public commitment to operate in line with UN SDGs, ensure sustainability is at the heart of our DNA and report annually to the UN on company progress.

Solutions such as our ground-breaking ECOSE® Technology, our revolutionary binder with no added formaldehyde, and our green roof solution Urbanscape® have both transformed the market with their eco-credentials and helped achieve the highest scores on green building rating schemes while being fully compliant with Estidama and Dubai Green Building Regulations. Our Glass Mineral Wool is manufactured with a minimum recycled content of 50%, the majority of which is post-consumer content, and its raw materials are harvested within a 500km radius.

We are also supporting our customers as they navigate an ever-changing landscape of demanding green building requirements and increasingly stringent environmental regulations.

What are your goals and plans for the next 4-5 years?

As demand for thermal and acoustic insulation grows, our outlook is optimistic. Knauf Insulation looks forward to expanding its presence across the region, with investments planned on strengthening staff and improving production capacity.

Our aspiration is to be the region’s most trusted insulation partner providing high-performing and smart insulation solutions and services. We are increasing our team’s numbers in regions where demand is surging faster to better support our clients and project developers, developing products aimed to reduce installation costs while fulfilling the fire and energy efficiency regulations and special solutions that will drive building designs to better integration between the natural environment and architecture.

Improving our facilities is how we seek to decrease our carbon footprint, production, and transportation costs. We plan to invest in production automation and efficient packaging by bringing new high-efficient equipment that will speed up production while decreasing manufacturing costs.

Our people are our biggest asset. We are committed to zero harm and building a culture of health, safety, and well-being. Training and development plans will ensure a strong community of engaged, committed, and focused employees, armed with extensive technical knowledge to be able to participate in our future decision making and to enhance our customer support.

What would be your one piece of advice for the new entrants in the industry?

Today the market is increasingly competitive. With the onset of globalization, it is easier to source products across the world, with an impact on the price level and profit margins. To be competitive today, an entrepreneur needs to set a long-term vision and have significant investments in technologies that can lower costs while being fully aware of the geographical and social-economic demands of the region in which the company plans on operating. What works in one region may not be the right approach in another.

To be successful in the insulation industry, a new company should design a strategy that involves establishing priorities and right approaches, thinking long-term rather than running to grab short-term opportunities. The business plan must integrate the investors’ ambitions with the more grounded realities of the environment it is set up in, retain the right talent and establish a decision-making framework to align the policies with the needs the company must serve.

Nowadays, it is also fundamental that the company culture reflects the mission, vision, and goals of the enterprise.