Reena Mukerjee looked up in horror at the smoke billowing from the 27th floor of the building which houses her office her own Architectural firm ‘Reema Athreya and Boon’, located on the top floor of this 39 storied glass clad high-rise. The fire safety was raging and as she watched some of the glass panels shattered and the flames leapfrogged towards the floor above. The high winds were helping the fire burn even more vigorously and it looked like very soon the entire structure above the 27th floor will be fully gutted soon. Only divine intervention can help. She prayed fervently with all her heart. “OH God! please do something. Please bring the fire to douse itself. Please save all those people who are stuck in the building and fighting for their lives”. Will her prayers be answered? It all depends.

This is a familiar scenario which plays out many times a year across India and any of us could be that Reena Mukerjee. Our colleagues, our family members or even we ourselves could be stuck in a similar situation. Unfortunately, there is no one on earth who can give you a guarantee that the building which houses your office or home can be made absolutely fire proof but if the architect, consultant and developer of such superlative high rise buildings decide to keep fire safety as a priority then they can definitely make the building extremely safe against fire accidents.

Fire safety and fire engineering is a vast and highly technical subject which is yet to become popular in India despite its criticality. When we speak about fire safety, we need to understand that this entire subject can be classified into two kinds of testing to classify the products.

- Resistance to fire which studies those properties of materials or their assemblies that prevents or retards the spread of excessive heat, hot gasses or the flames across different compartments in the building during a fire.

The classification for resistance to fire will be as follows:

E30 to E120 where E denotes the ability of the product or system to have integrity to prevent the spread of flames and smoke/gasses and 30, 60, 90,120 denoting the number of minutes the product or system successfully stops this. (The NBC specifies E120 and EI 20 as the bare minimum requirement for doors and partitions used in the escape corridors and refuge areas).

EW 30 to EW 120 where EW denotes the ability of the product to not just stop the spread of fire and smoke but also ensure that the radiation passing through the glass and frame of the system is always below 15KW per Sq m per hour. This is the minimum radiant heat required to have spontaneous combustion happening on the non-fire side during a fire. As such, most specifications worldwide fall in this category.

EI 30 to EI 120 where EI denotes the not just the fire resistant properties but also the insulation properties of the system thus ensuring that the maximum temperature on the non-fire side never exceeds 1850C.

- Reaction to classifies materials on the basis of how they behave during a fire to withstand fire exposure. This can be broadly classified for the following characteristics

Flammability from A1, A2 to F where A is non-flammable and F is unfit to be tested since it is highly combustible.

Smoke index from S0 to S3 where 0 means low smoke and 3 is heavy smoking if the product is on fire

Burning droplets from d0 to d2 where 0 means no burning droplets are produced during fire and 3 being high number of burning droplets falling down which can create secondary fires.

Based on these characteristics there are two kinds of agencies who certify the products to be used in buildings.

- International certifying bodies that use the data generated during the testing either in their own laboratories or in third party accredited laboratories and then classify the products either according to international standards or their own (UL). These certifying also audit the manufacturing process of the manufacturers and undertake to do random tests on samples to ensure that the product sold is as per the tested specification. There are several reputed such agencies worldwide and UL, INTERTEK, FM GLOBAL, EXOVA are a few well-known brands.

The most important aspect to be kept in mind is that when a system gets tested and certified the certification holds good only if all the components which were used in the original test is used fully while the system is manufactured in the factory. Even if any one component is replaced, then the validity of the test report will become void.

Once again there are two kinds of products which go into a building which focus on fire safety.

- Passive fire products or systems are those which are built into a building to prevent the spread of fire and smoke from one zone to another within the building for the specified period, by virtue of its physical properties, as mentioned in the local specifications. These products need no manual or other intervention to start working in the event of a fire. Examples of passive products are fire doors, fire rated partitions, Penetration seals, Ablative paints, in tumescent collars or tapes etc.,

- Active fire products or systems which focus on containment and extinguishing of the fire in the building. These require human or automated intervention to get the system working in the event of a fire. Examples of active fire systems are fire extinguishers, smoke extraction systems, smoke alarms and detectors, etc.

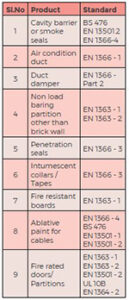

Once tested products and systems are used in the building the risk of fire incurring and spreading reduces drastically. The chart attached below gives the details of most commonly used passive products in buildings for fire safety and their relevant testing specifications.

Fire safety is a vast subject which has gained immense interest in India in the recent past. However, in most advanced countries this is a very critical subject which is dealt by professionals with the utmost seriousness it deserves. The objective of the fire specialist would be to make the building as fire resistant as possible by ensuring that only tested and certified products are used in the project. No doubt such tested and certified products would be more expensive, but then that is the price one needs to pay to keep human life safe in these buildings.

Fire happens in a building mostly as an accident and sometimes as a result of arson. Irrespective of the causes let us stick to how its impact on the people who occupy that building and the building itself can be minimised. The focus for the fire consultant would be to design the building in such a way that even if there is an outbreak of fire it is confined to a limited zone or compartment for as long as it’s necessary. This gives adequate time to the occupants to evacuate safely out of the building, without panicking, while the active systems get triggered on to douse the fire. At the same time, this will also allow the fire rescue teams to access the hot zone without any hindrance.

When it comes to façades there are only three critical areas which need to be taken into consideration to make the façade resist the fire from spreading.

- The gap between the curtainwall glazing system and the floor slab is one of the most critical zones which need to be adequately protected in the event of fire to prevent the “chimney effect” spreading the smoke and fire to the floors above. A well designed smoke seal or fire barrier which uses a certified system is something which the consultant should never compromise on, come what may.

- The height of the spandrel panel must be designed for a minimum of 950 mm and the material used in the spandrel panel must be fire rated for a minimum B2 classification to prevent a “leapfrogging effect” i.e. the fire jumping from one floor to a higher floor after the glass panel in the curtain wall explodes with the intense heat.

- A well designed water sprinkler system within 600 mm from the glass façade inside the building to ensure that the glass temperature stays low thus preventing the glass from shattering.

A well designed curtain wall has no inflammable components and can never aid or abet the spread of fire. The hundreds of fire accidents which continue to occur worldwide give the fire professionals enough clues about why the fires occurred and what could have been done to prevent it and even if it was not preventable how to minimise the losses. It is important that every professional working on the design and execution of high rise project keep fire safety in mind while designing. Fire can be accident but the consequential damage from that fire need not be left to chance. With all the information on fire safety freely available on the net no one can take umbrage under the excuse that they did not have adequate inputs while designing the project.

Even within the building care must be taken to minimise the use of inflammable products made of wood or polymers and make the building more resistant to fire. Certified passive products must be used wherever necessary in the HVAC ducts, cable trays and pipes as they travel through the building from one compartment or one floor to another. These passive fire products get to work in the event of a fire and prevent the smoke and fire from spreading through the HVAC ducts and the space above the false ceiling. As we all know smoke kills more people in the event of a fire than fire itself and therefore every fire safety system must also consider the risk of smoke spread along with fire.

All the doors facing the escape corridors must be fire rated to keep these zones free of smoke and fire for at least 120 minutes. This will allow the occupants to reach safe zones without panicking. The fire-rated doors and partitions must be tested and certified as a complete system and not assembled by the supplier with test certificates from individual component manufacturers. Such a product has no one agency giving the guarantee and in the event of a fire there will be a lot of finger pointing going round to take the blame when the system fails.

Damage to life and property can avoided or at least minimised if a proper fire safety design is built into a high rise project. Then even if there is a fire no one needs to panic as there is a built-in system to ensure that the occupants reach a safe zone without any loss or injury. Coming back to the Reema Mukerjee story, she remembered clearly the focus she and her team had put in while designing the fire safety systems for this project and she believed that these systems will ensure that this fire does not go out of control. Half an hour later she got a call from her partner telling her that she along with all her team members are safe and the fire services have reached the spot and doused the fire. Under these circumstances, the fire code book that she had referred was a life saver like any other holy book she had read.