The façade industry is at a cusp as our cities are growing taller. Fire safety, performance, and aesthetics of a high-rise building façade is a complex issue. Therefore, stakeholders’ involvement, including specialist façade consultants with the help of relevant codes and standards, ensures performance-based design. Material manufacturers, suppliers, and vendors also have upped the ante with the technical presentation, technical teams to explain solutions, performance criteria, and test certificates being made available by them to select the best technological solutions and material choices for all stakeholders.

Investment in performance mock-ups before execution additionally helps to check and improvise on the designs. On the same lines and on a positive note, the industry has embodied and improved manufacturing techniques to ensure quality. Manufacturing happens in a controlled environment, which provides the product manufactured goes through stringent quality checks before being dispatched. The quality check parameters coincide with approved system drawings and specifications if the material and contractor chosen are prequalified based on design and technical expertise and not just cost.

However, installation at the site is labour intensive in spite of the usage of cranes, cradles, etc. Upskilling and industry-specific training are not generally available. The guiding parameter and correct positioning or installation remain labour dependent. Today, cladding material installation, glazing panels or ACP, Aluminium cladding sheets or clay tile, or any other material is typically contracted to a subcontractor for the installation. Most of the façade vendors have a maximum of 20% of the workforce for site execution. They are deployed either for supervision or for working as a backup for the eventuality.

With the advent of speed and gamut of execution, supervision at all locations by qualified façade engineers remains a challenge. One of the biggest challenges for highrise buildings today is the facades’ installation process. In most projects, installation of the facades starts before the completion of the main structure, which involves risks of tolerance difference between floor construction of the facility and the façade, breakages, half-done works, and in some cases, damage to completed works.

According to the installation contractors, coordinating the installation works with other trade contractors’ activities remains the most significant hurdle and a challenge. Performance safety parameters of highrise building façades are a complex problem. Therefore, the prescriptive of just design or manufacturing being correct is not sufficient to ensure a proper building level performance and especially fire safety level.

Façade inspection is an integral part of installation quality as it helps to verify the integrity of the structure and ensures safety for its occupants. However, current conventional façade inspection is time, labour, and cost intensive. With technological advancement and changing facets of how we execute projects, I truly believe there will be more and more intelligence in the façades to manage and optimise.

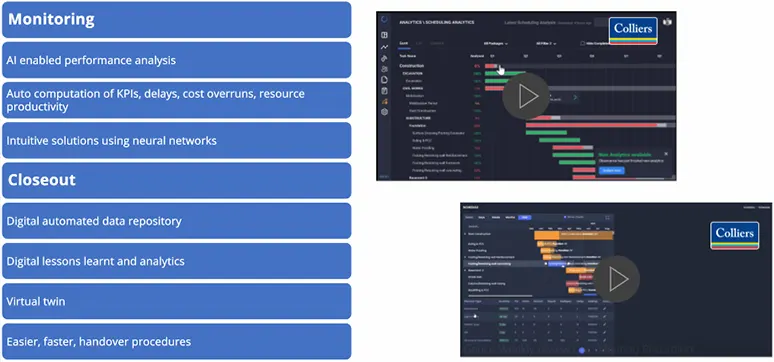

A significant share of the added value during execution and on-site audits of the façades will be through artificial intelligence and how the various workflows and sequences are implemented at the site. If done correctly, we will be able to provide the entire solution, which is compliant with the design intent.

Next-generation smart façade inspection drones:

The drones with high-resolution visual and thermal cameras can accurately scan the interior and exterior of buildings. These images can be compared with numerous pre-defined photos / stored in a computer program. Through Artificial Intelligence, the alarms can be generated if the current installation is not as per drawings or design intent, or the execution quality doesn’t comply with set acceptance criteria. This technological advancement may not substitute the interface of human audit, but it can help to reach all locations where works are in progress.

Developed by TUV SUD and partners and other start-ups outside India may make such inspections easy and drive the vendors to attain the next level of quality audits.

This service caters to building operators and owners of large highrise buildings and helps construction companies to ensure façade quality and monitor the construction progress of their projects. Inspection levels can be based on:

- Type of façade and material used

- Type of installation checks

- How tall the building is

- Performance and tolerance guidelines

The drone-based close level inspections will throw up comparing criteria around:

- Material used if integrated with frameworks like SAP, Autodesk software, etc.

- Installation checks followed at the site

- Installation tests were done at site and records around the same with in camera recoding

- Corroborating installation with the design intent

- Any avenue of water infiltration, gaps between various materials, cracks, splits into joint sealants, missing pieces like flashing, fasteners, gaskets, etc.

- Loose, missing, or cracked structural element to which façade is anchored to

- Breakages, cracks of interior and exterior

- Accurate measurements

- Comparison with schedule

- Accurate prediction of progress at the site if integrated with BIM Model

Getting AI and ML to work for a façade audit will help as AI algorithms can scan through terabytes of data, looking for inconsistencies or hidden patterns that a human might overlook at first. For example like, T2D2, a computer-vision, machine-learning algorithm, and the engineers at the lab can now identify damage to building faced by auditing and comparing the images and video recordings. Such algorithms can do fire level inspections before a façade engineer can go to the exact location and do a more thorough assessment to find solutions. The beauty of AI and ML is that as we feed more and more images and execute more projects, the library of events can help reinforce the learning and improve the gradual models to enhance the usage. A similar partnership between H3 Dynamics and ELID Technology may, in the future, help robots even to execute repair tasks.

Regulatory audits around façade inspection by a qualified engineer with rigid forms and requiring building owners to produce certificates will bring in stepped up the quality of work execution and help scale up the acceptance criteria based on performance checks. Façade inspections are also an integral part of effective facility management. Such AI-driven inspection can help facility and property managers accurately forecast the expected capital expense and mitigate predictive risk. In more and more countries like Singapore, the US, and the UK, local ordinances have been enacted laws. However, they are city and regional-specific.

However, a program or algorithm can be a part of the solution. Skill training, as mentioned earlier, of the execution team needs to enhance. Coupled with the drone surveys, a complete façade inspection with stringent process control and digitisation of the work process will ensure the quality of execution is correct and is for the intended usage. The writer recommends that under the skill development program, Govt of India may notify colleges or bodies to award a time-based certificate to engineers and architects for façade inspection. This will help to have a pool of qualified personnel.