Mr. Om Prakash Goel was stressed out. His only daughter was getting married to the scion of one of India’s largest construction companies. The wedding had to be grand and the food – memorable as guests finally remember a marriage only by the food served.

And he had to choose the caterer today! He had four choices.

-

Mock-up of skylight system Shub Catering: a company that claims to be the biggest in the business -capacity to feed 5000 people in one sitting. The owner was a friend of a friend. Feedback from the market: sometimes the food is good – other times -so so.

- Deliciously Yours: Owned by a NRI from Canada who promised gourmet food sourced worldwide. Good testimonials from expat Indian UK, US and Canada about the food. But he was new in India and was just settling down.

- Badhai Ho: A local caterer just establishing his presence with good quality food and excellent range of cuisine. Mr. Goel has tried the food at one of his friend’s marriage.

- New Delhi Caterers: A caterer with 30 years experience who will only serve traditional food which is economically priced, but service is terrible.

Just three months to the marriage and this decision has to be done in the next three days.

If you were in Mr. Goel’s place, how would you choose?

Least expensive, friend of a friend or application of a logical process to evaluate individual capabilities based on some established parameters such as:

- Prepare three or four sample dishes which were definite on the guest menu to be sampled by close family and friends.

- Visit the caterer’s office to see the infrastructure to prepare the food required and review videos& testimonials of the past marriages catered.

- Get at least three recent references of marriages/events conducted and speak to the client directly to get a feel of what to expect.

Choosing a façade contractor to supply for your project also needs a rational and established process to finally choose the most suitable supplier.

- To begin with, there needs to be clarity on the specifications. What is expected of the system depends on the location, height and target market it is catering.

- Once the specification is clear, then the easiest way to choose is by having a set of preconditions for potential contenders.

a) Do they have the technology to deliver what is needed

b) What is their track record to complete in time

c) Do they have a proper factory and infrastructure to deliver consistent quality

d) How skilled is the team or is it a one man show

e) The important qualifying factor is whether the product has been tested and certified by a third party based on some established parameters. (The proof of the pudding is always in the eating!)

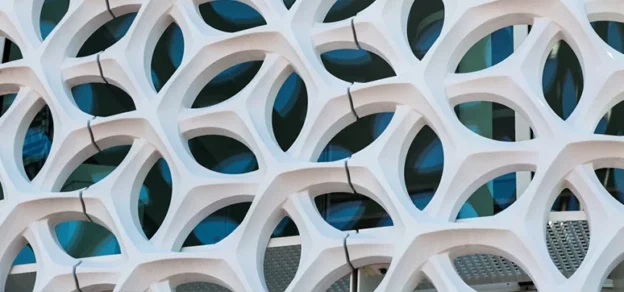

Facades, windows, doors and hand rails have been used in projects world over for decades. Standards to evaluate them have also been established to evaluate their performance based on the parameters expected for performance.

This expectation has been refined over the years by actual users and their cumulative experiences have formed a part of process in the evolving of the standards. So why reinvent the wheel when the job has already been done and endure the pain of uncertainty?

A façade is made up of several components such aluminium, glass, gaskets, hardware, silicone sealant etc. When the performance of all these components has to be tested concurrently, it is safer to rely on established norms rather than experiment. Making a product with a test certificate is the minimum qualification – it will ensure suppliers with similar capabilities and make the choice obvious.

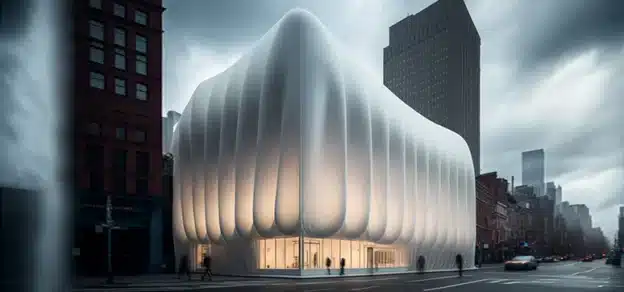

For a façade contractor in case of large projects, once the supplier is chosen, a sample of the product (same dimensions and features to be used in project) is installed at a testing lab and tested for the performance specified and witnessed by all stake holders. If there is any failure, the root cause is identified and corrective action done. Retest is carried out till it passes all specifications laid down by the consultant. Once this is done, you can be almost totally-assured value for your money.

But how to ensure the same care is taken with all the units delivered at the project site? For a façade contractor On Site testing resolves this by testing random units when carried out by an impartial third party testing agency. This process ensures that all parties involved in the supply & installation follow established process and ensures no slippages in any stage of the entire process.

To return to Mr. Om Prakash Goel, he is a happy man today. The marriage went off smoothly and the grooms’ side were very pleased with all the arrangements. The highlight was the food. It was a huge hit and Mr.Goel was thanking his stars for making his family and close friends to taste the food before finalising the caterer.

And that my friends made ALL the difference…